Geocomposite Geomembrane

The composite geomembrane liner has the advantages of geomembrane and geotextile at the same time. Geomembranes provide excellent seepage, leak, moisture, tear, and puncture resistance. The geotextile layer increases the tensile strength, and the composite geomembrane lining plays a great role in the landfill.

Description of composite geomembrane

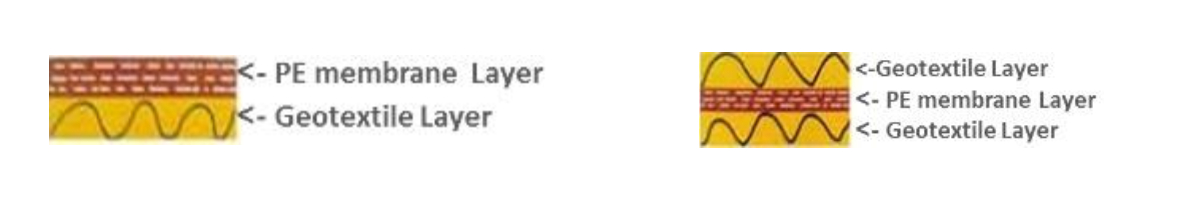

One geotextile and one geomembrane(geotextile: 100-1000g/m2; geomembrane thickness: 0.1-1.5mm)

Two geotextiles and one geomembrane(geotextile: 80-600g/m2; geomembrane thickness: 0.2-1.5mm)

One geotextile and two geomembranes (geotextile: 100-1000g/m2; geomembrane thickness: 0.1-0.8mm)

Many geotextiles and many geomembranes (geotextile: 100-1000g/m2; geomembrane thickness: 0.1-0.8mm)

.

Item | Index | ||||||||

Nominal Breaking Strength (kN/m) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

1 | Tensile Break Strength MD&CD (kN/m) | ≧5 | ≧7.5 | ≧10 | ≧12 | ≧14 | ≧1 6 | ≧18 | ≧20 |

2 | Standard Break Elongation MD&CD % | 30 〜100 | |||||||

3 | CBR Breaking Strength /kN | ≧1.1 | ≧1.5 | ≧1.9 | ≧2.2 | ≧2.5 | ≧2.8 | ≧3 | ≧3.2 |

4 | Tearing Strength CD&MD kN | ≧0.15 | ≧0.25 | ≧0.32 | ≧0.4 | ≧0.48 | ≧0.56 | ≧0.62 | ≧0.7 |

5 | Resistant to Hydrostatic Pressure MPa | According to Table 2 | |||||||

6 | Peel Strength (N/cm) | ≧6 | |||||||

7 | Vertical Permeability Coeffcient (cm/s) | According to Design or Contract Requirement | |||||||

8 | Width Deviation % | -1.0 | |||||||

Item | Geomembrane Thickness (mm) | ||||||||

0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | ||

Resistant to Hydrostatic Pressure (Mpa)≧ | Geomembrane With One Side Geotextile | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.6 |

Geomembrane With Two Side Geotextile | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | |

Advantages of composite geomembrane:

High Tensile Strength.

Outstanding Chemical Resistance.

Superior Waterproofing & Drainage.

Comprehensive Barrier Protection.

Excellent UV Resistance.

High Tear & Puncture Resistance.

Low-Temperature Flexibility.

Quick & Easy Installation.

Cost-Effective Solution.

Anti-Aging & Corrosion Resistant.

Composite Geomembrane Application

It is an ideal impermeable material, widely used on basement and rooftop waterproofing, roads, highways, railways construction, channels, dikes, reservoirs, dams and transportation tunnels as reinforcement, etc.

Packaging Details & Delivery Time

We guarantee safe packaging and prompt delivery to align with your project schedule. Backed by ample inventory and high-efficiency production, we deliver geosynthetic materials fast—exactly when you need them.

Company Profile

Established in 2012, Shandong Yibo Yangguang Engineering Materials Co., Ltd. has earned a strong reputation among leading global contractors as a trusted provider of geosynthetic solutions. Our product portfolio includes geotextiles, geomembrane liners, erosion control materials, and site management supplies, widely applied in infrastructure, environmental, and civil engineering projects.

Our products are exported to a wide range of international markets, including Europe, the United States, Southeast Asia, Africa, and other regions, reflecting our commitment to quality and global reach.

The company operates more than ten advanced production lines, supported by state-of-the-art equipment, including:

Automatic wide-width geomembrane production lines

Geomembrane surface roughening units

Non-woven fabric production lines

Composite geomembrane production lines

Bentonite waterproof blanket production lines

Polymer self-adhesive waterproof membrane production lines

To ensure quality and efficiency, we maintain high-standard manufacturing workshops, well-equipped laboratories, and comprehensive infrastructure, including storage centers, transfer hubs, and finished goods warehouses. This integrated setup enables us to meet both domestic and international demands with speed, consistency, and reliability.