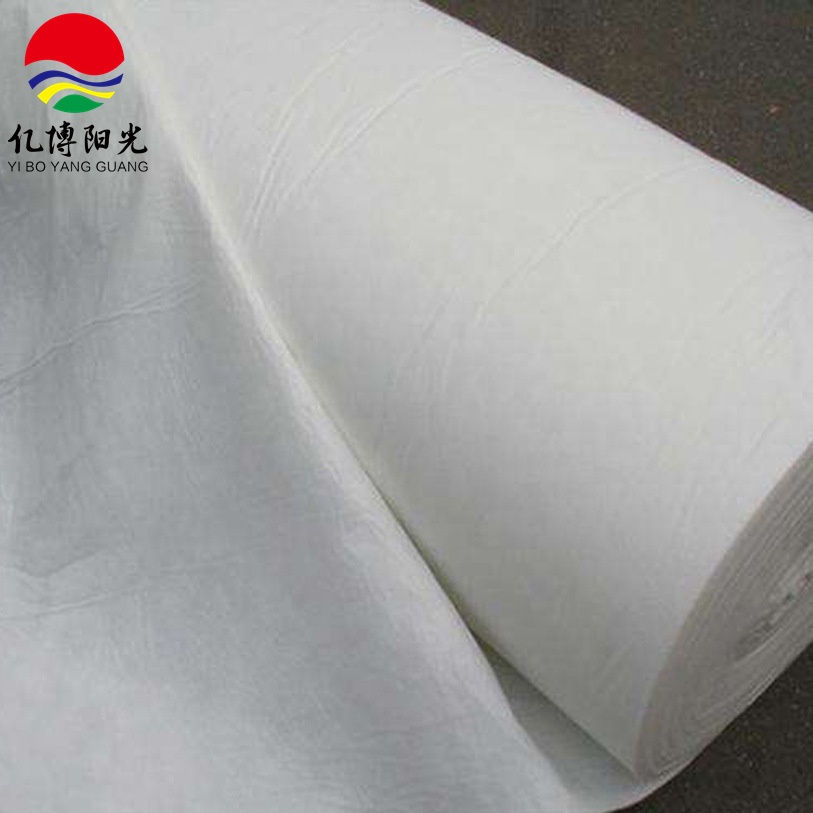

Geofabric

High Chemical Resistance: Durable against acids, alkalis, and other chemicals.

UV & Weather Resistant: Reliable performance in outdoor conditions.

Superior Puncture Resistance: Withstands heavy loads and sharp objects.

Excellent Filtration & Drainage: Prevents soil migration while allowing water flow.

Flexible Installation: Easy to cut, weld, and lay on-site.

Cost-Effective: Long service life with minimal maintenance.

Product Introduction

Geofabric often called geofabric or driveway fabric, is a synthetic material placed under the gravel, stone, or pavement of a driveway. It's not just an optional extra; it's a crucial component that acts as a stabilizing layer between the soft subsoil and the aggregate base, significantly extending the driveway's lifespan and reducing maintenance.

Product Specifications

| Material | 100% Polyester (PET) Staple Fiber |

| Fabric Type | Needle-Punched Nonwoven Geotextile |

| Weight Range | 80g/m² – 1500g/m² |

| Width | 1 meter to 8 meters (customizable) |

| Length | Customized based on project requirements |

| Color | White, Black, Grey (or customized) |

| Standards | GB/T17638-2017 — Geosynthetics — Staple Fiber Needle-Punched Nonwoven Geotextile JT/T520-2004 — Geosynthetics for Highway Engineering — Staple Fiber Nonwoven Geotextile |

| Key Features: | High chemical and UV resistance Excellent puncture and tear strength Superior water permeability and filtration Flexible and easy to install Long-lasting and cost-effective performance |

Application

Separation & Stabilization: It prevents the mixing of subgrade soil with crushed stone aggregate, distributes the load, and reduces rutting.

Drainage & Filtration: Prompt removal of water from within the roadbed prevents water damage and also prevents soil particles from clogging the drainage system.

Reinforcement & Erosion Control: To enhance the overall bearing capacity of the roadbed, especially on soft soil roadbeds; to prevent soil erosion on slopes.

Packaging & Delivery

Customized Packaging

Optional waterproof polyethylene wrapping or reinforced edge protection for long-distance or sea freight.

Rolls can be palletized and shrink-wrapped for easier handling and forklift operations.

Special Requirements

For large projects, rolls can be bundled and loaded in 20ft or 40ft containers with optimal space utilization.

Hazardous material packaging is not required as geotextiles are environmentally safe.

About Us

Yibo Yangguang maintains a rigorous quality management system to ensure product excellence:

Certification Compliance: The company holds ISO 9001 quality system certification, ISO 14001 environmental system certification, and occupational health certification. Products also carry CE certification and comply with ASTM standards.

Quality Control System: The company implements a comprehensive QC system where each production batch undergoes sampling and testing. Samples are retained for 5 years to ensure traceability and quality consistency.

Our Company Services

Raw Material Control: The company utilizes 100% virgin materials with technical formulations to ensure product quality and performance consistency.

Quality Control Personnel: The company maintains 45 dedicated QA/QC inspectors who conduct pre-production sampling, in-process inspections, and final inspection before shipment.

Traceability System: The company implements product traceability protocols that track raw materials through the entire production process, ensuring accountability and facilitating quality audits.