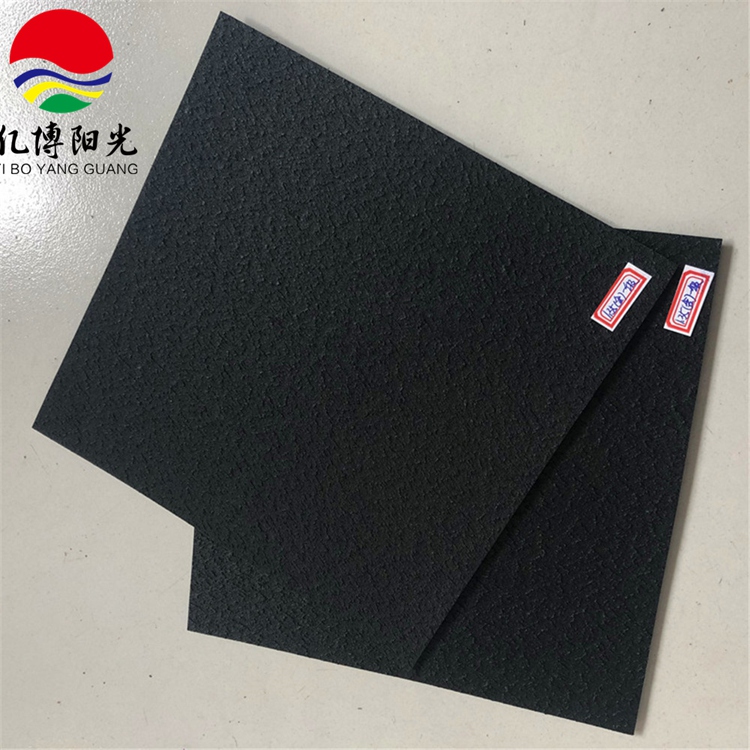

High Quality Textured HDPE Geomembrane

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

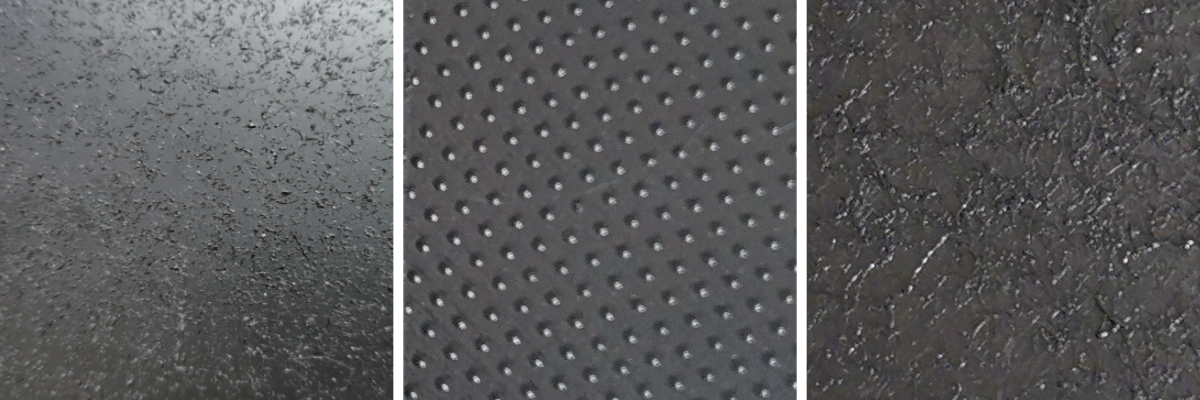

The spinning (single/double) rough surface HDPE geomembrane is made by roughening smooth HDPE film to create a textured surface. This improves friction and stability, making it ideal for landfills, slopes, and mining projects. It also retains the strength of smooth geomembrane while offering better tensile performance.

The column point HDPE geomembrane is made from virgin resin using a flat extrusion process, forming a surface with uniform raised points. This texture boosts friction and drainage, making it suitable for projects like environmental protection, water conservation, and underground construction.

Product Specifications

Parameter | Specification |

Thickness | Textured surface 1.0mm–2.0mm |

Width | Textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Textured/ Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surface textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Application Scenarios

Our geomembranes are widely used to prevent leakage and protect the environment in various projects. Main applications include:

Municipal projects – Preventing soil and water pollution in waste and water systems.

Landfills – Acting as barriers to stop harmful liquids from leaking into the ground.

Sewage pools – Providing strong, chemical-resistant liners to hold wastewater safely.

Metallurgical and petrochemical sites – Containing hazardous materials and preventing pollution.

Tailings ponds & red mud piles – Safely storing industrial waste from mining and aluminum production.

Power plant ash dams – Securing coal ash and other residues to protect soil and water.

Thanks to their excellent durability, chemical resistance, and strength, our geomembranes are trusted in demanding engineering and environmental projects.

Why choose us?

Our company has more than 20 product patents. We are industry director association members, participate in customized product standards, and can customize services according to engineering needs.

Provide complete solutions for product design, delivery, and installation for construction projects.

Offering a variety of complementary product portfolios and contract projects.

We have a laboratory to test products.

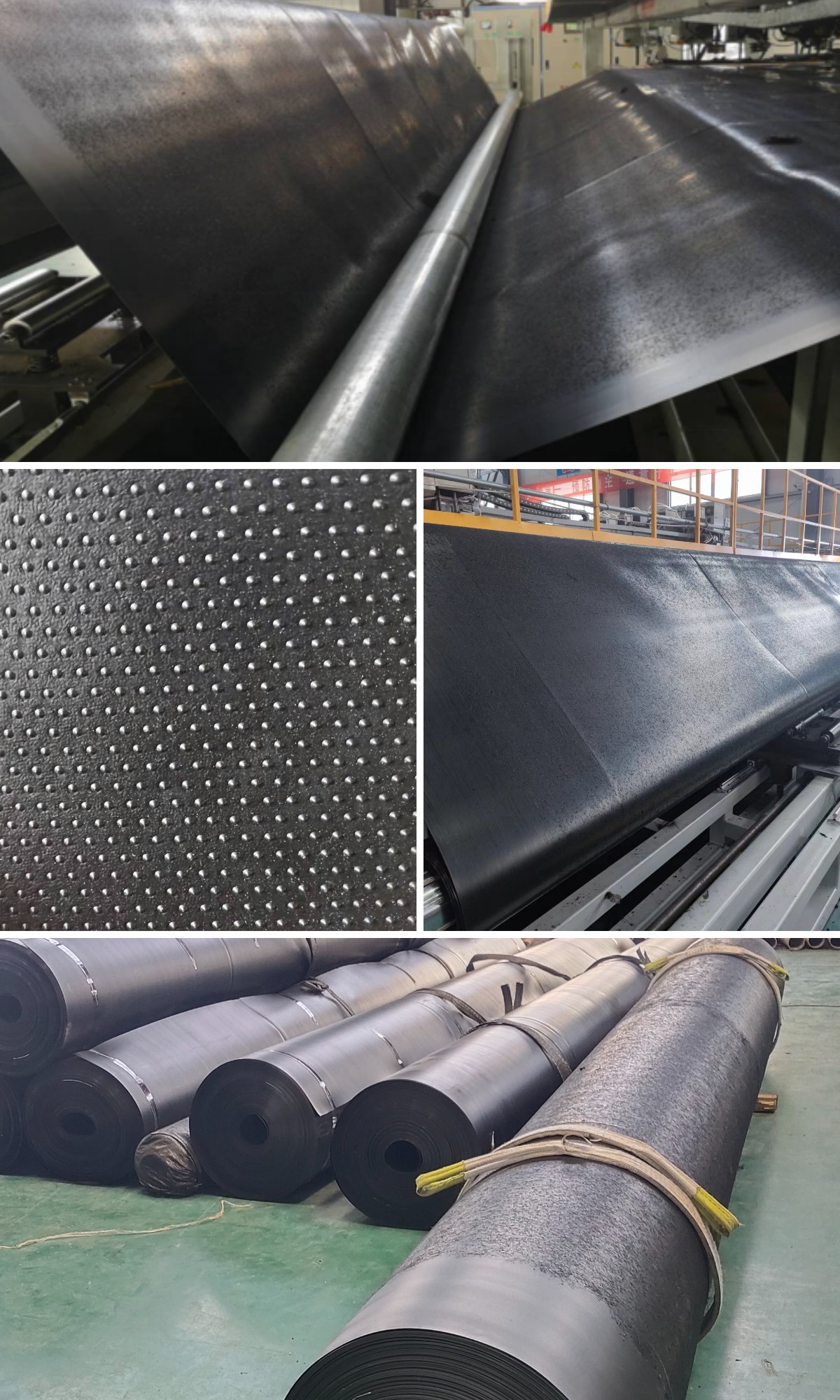

Packaging & Delivery

We ensure secure packaging and fast, reliable delivery to keep your projects on schedule. With strong production capabilities and a large inventory, we can quickly handle orders of any size, anywhere.

Our packaging follows strict industry standards to protect products during shipping. Each order is carefully packed to maintain quality from our factory to your site.

Key benefits include:

Fast Delivery: Quick dispatch for in-stock items

Reliable Shipping: Safe, on-time delivery worldwide

Quality Packaging: Strong, protective materials suited to each product

Custom Options: Special packaging available if needed

Our 24/7 logistics team tracks all shipments and provides real-time updates, ensuring everything arrives on time and ready to use.

"Your business, we guarantee" – from packing to delivery, we’ve got you covered.

About Us

Shandong Yibo Yangguang Engineering Materials Co., Ltd. is a high-tech enterprise based in Laiwu High-tech Zone, Jinan, Shandong Province. We specialize in the R&D, production, sales, and construction of geotechnical materials and related products.

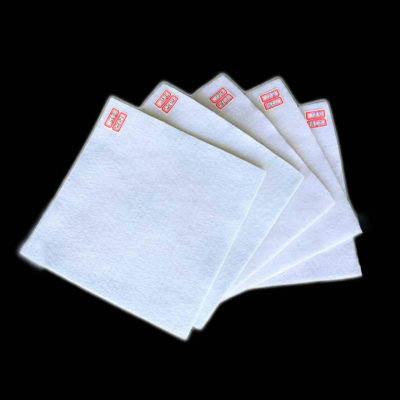

With a focus on innovation and quality, we offer a wide range of geosynthetic solutions—including geomembranes, geotextiles, geogrids, and drainage materials—widely used in environmental protection, infrastructure, mining, water conservation, and energy projects.

We provide complete services from product development to on-site support, ensuring durability and performance. Backed by a skilled technical team, we serve both domestic and international markets with reliable, standards-compliant solutions.

We are specialized in the development, manufacturing, sales, and construction of geomaterials and their supporting products, specializing in the production of HDPE geomembrane, Rough geomembrane, Composite geomembrane, EVA waterproof board, Polymer self-adhesive waterproof board, Bentonite waterproof blanket, Filament (short silk) geotextile, Composite drainage net and other geomaterials products.

Our Company Services

We are proud to have a team of competent and highly knowledgeable technical engineers with extensive experience in the geotechnical and civil engineering fields. Their deep understanding of industry standards, construction challenges, and material behavior ensures that clients receive expert guidance and technically sound solutions at every stage of the project.

Our team offers customized services tailored to the specific requirements of each engineering project, taking into account site conditions, environmental factors, and project objectives. Whether it’s material selection, structural recommendations, or on-site support, we adapt our approach to meet your unique needs.

We provide comprehensive, end-to-end solutions that cover every aspect of construction project execution—from product design and technical consultation to delivery logistics and on-site installation support. This integrated service model helps streamline workflows, reduce delays, and ensure long-term project success.

In addition, we offer a diverse portfolio of complementary geotechnical products and contract project services, enabling clients to source multiple materials and solutions from a single trusted provider. This includes geosynthetics, waterproofing systems, drainage materials, and other engineering essentials, making us a one-stop solution for infrastructure and environmental construction needs.