Geocomposite Drainage Net

1. Fast drainage: Efficiently guide and drain accumulated water.

2. High strength: Resistant to pressure and not easy to deform.

3. Good soil filtration: Prevent sand and soil from clogging.

4. Corrosion resistance: Adapt to a variety of environments.

5. Easy construction: Lightweight and flexible for laying.

6. Long service life: Durable, stable and long-lasting.

Production introduction

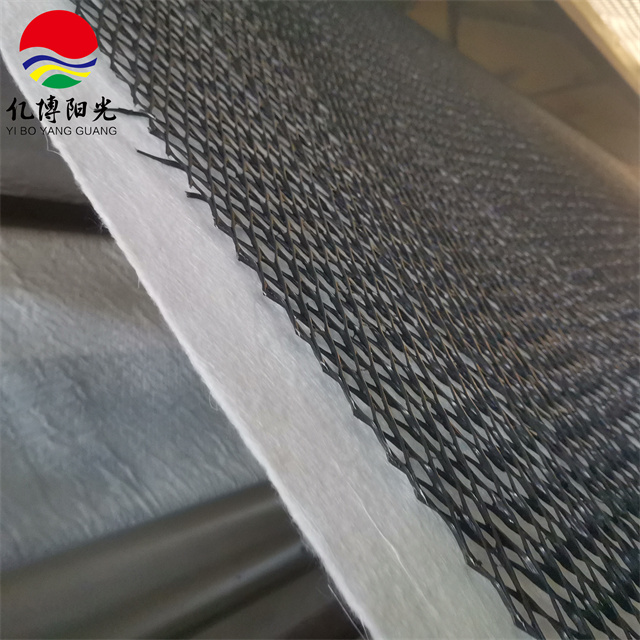

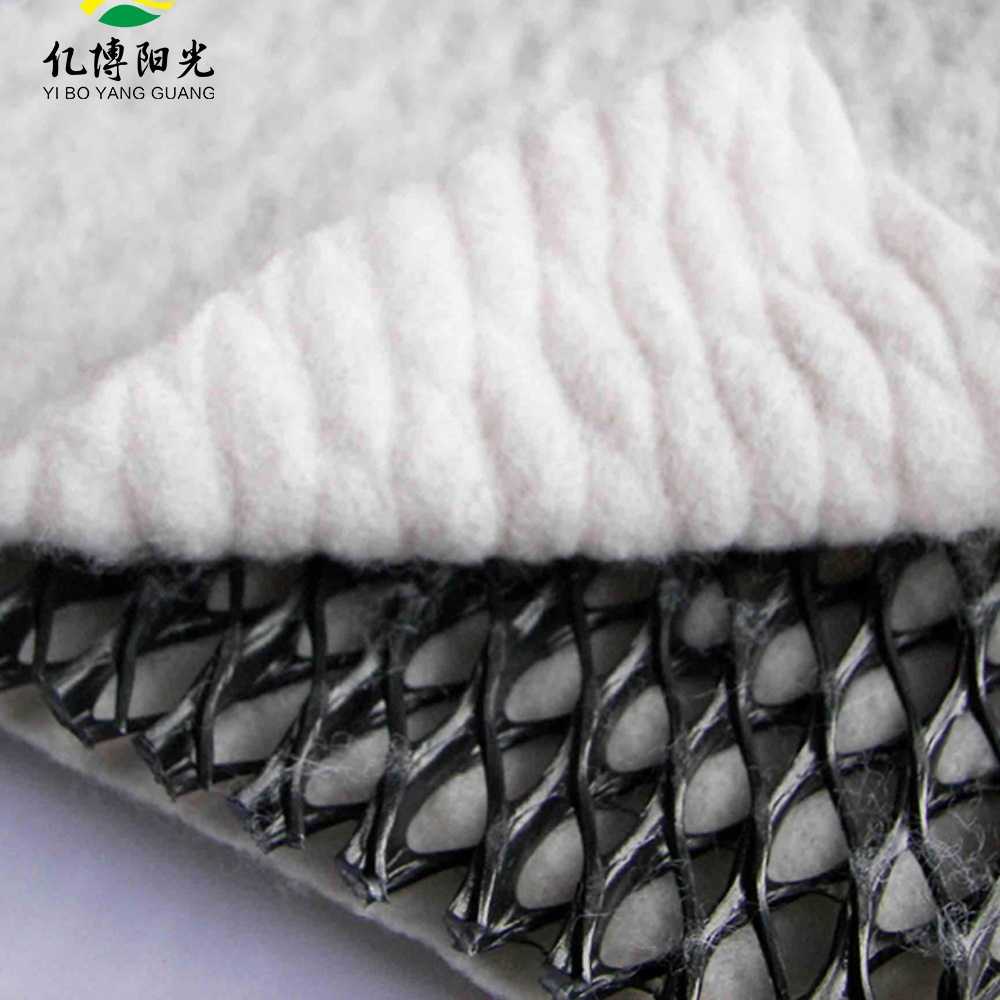

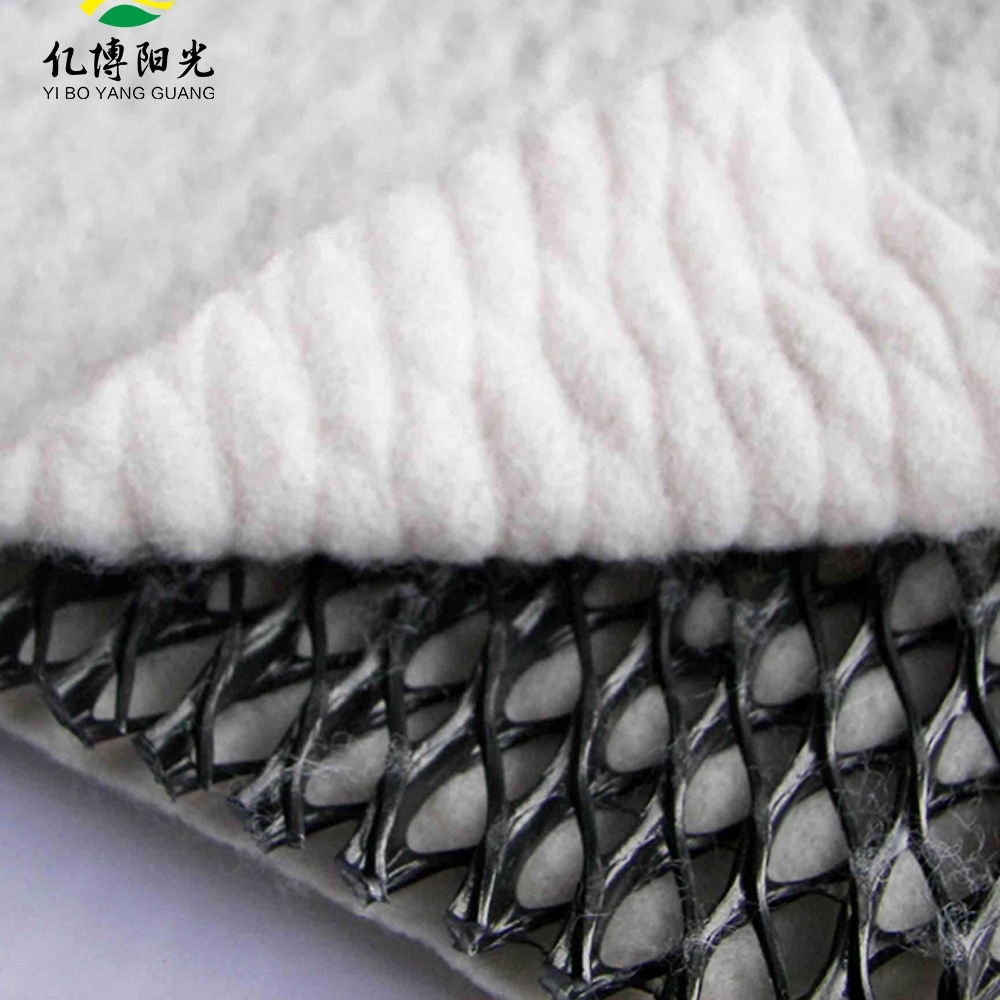

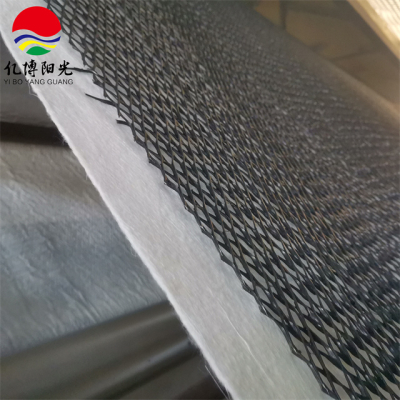

A prefabricated geosynthetic construction made up of two geotextile filters (either woven or non-woven) and a high-strength polymeric net core is called a geocomposite drainage net, or geonet drainage composite. Continuous drainage channels are produced by the uniform grid or hexagonal design of the net core, which is usually composed of polyethylene (PE) or polypropylene (PP). Water can freely flow through the geotextile layers, which serve as a filter to keep soil particles from obstructing the drainage channels. The main issues of water management in environmental engineering and construction are addressed by this integrated structure, which guarantees effective water flow, soil retention, and structural reinforcement.

Production Specification

| Country of origin | China | Colour | Black |

| Brand | YIBO | Certification | ISO9001 |

| Size | 4mm-8mm | Length | 20m-50m |

| Material | HDPE | Width | 1-6m |

Application scenarios

Road Engineering: It is used for the drainage of road subgrades, reducing the groundwater level, improving the stability and strength of the subgrade, and reducing road diseases.

Landfill: A landfill is an important facility that centrally disposes of waste, protects the environment through pollution prevention and control measures, achieves a certain degree of resource utilization, and maintains urban sanitation.

Key Features & Benefits

Superior Drainage Capacity: Even at high hydrostatic pressure, the 3D net core design's clean internal channels and wide void space (up to 90% porosity) allow for quick water flow rates. In both horizontal and vertical drainage applications, it performs better than conventional granular drainage materials.

High Tensile Strength & Durability: Made from high-quality PE/PP polymers, the drainage net has outstanding defenses against mechanical damage, UV rays, chemical corrosion, and biological deterioration. It guarantees a service life of more than 50 years by retaining its structural integrity in challenging soil and environmental conditions.

Lightweight & Easy Installation: Our geocomposite drainage net is lightweight (usually 200-500 g/m2) and comes in rolls up to 50 meters long, unlike gravel or sand, which need large gear for transportation and placing. This minimizes site disturbance, cuts down on construction time, and lowers labor expenses.

Soil Stabilization & Reinforcement: By combining geotextile with geonet, soil erosion is avoided, loads are distributed uniformly, and soil shear strength is increased. It is perfect for strengthening retaining walls, embankments, and slopes, lowering the chance of structural collapse and landslides.

Economical: Significant project savings are achieved through quicker installation, less maintenance, and lower material transportation costs. It is a cost-effective and sustainable substitute since it does not require large amounts of granular ingredients.

Why Choose us.

Longer Service Life: Our geomembranes offer a service life of over 4 years, ensuring long-term performance.

High-Quality Materials: Manufactured using 100% virgin HDPE, enhanced with carbon black, antioxidants, anti-aging, and UV-resistant additives for excellent tensile strength and puncture resistance.

Strong Technical Capability: Equipped with advanced testing equipment and a professional inspection team, we ensure consistent quality for every batch of geomembrane products.

Reliable Barrier Solution: Produced through the blow molding process, our HDPE geomembrane liners effectively prevent liquid leakage and gas volatilization. We offer both HDPE and EVA material options based on project requirements.