Water Conservancy Project Use Composite Geomembrane

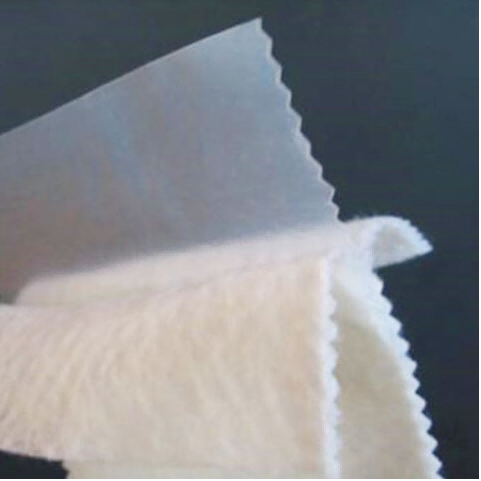

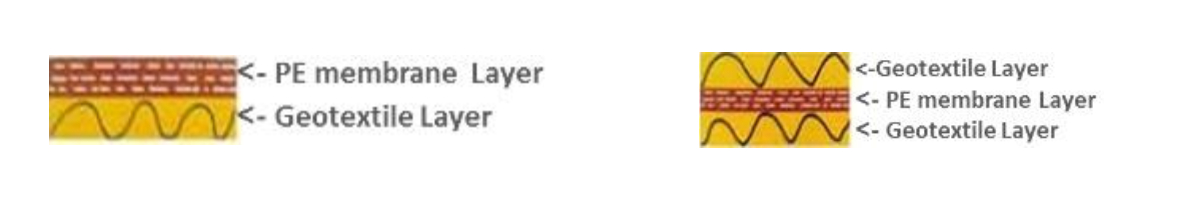

Composite Geomembrane (Geotextile-Geomembrane Composite) is created by heat-bonding a nonwoven geotextile layer to a geomembrane. This composite combines the benefits and features of both materials. The geotextile enhances the system by offering better puncture resistance, tear propagation control, and improved frictional properties, which help reduce sliding. Additionally, the geotextile itself contributes tensile strength to the overall structure.

Composite Geomembrane Specifcations

Item | Index | ||||||||

Nominal Breaking Strength (kN/m) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

1 | Tensile Break Strength MD&CD (kN/m) | ≧5 | ≧7.5 | ≧10 | ≧12 | ≧14 | ≧1 6 | ≧18 | ≧20 |

2 | Standard Break Elongation MD&CD % | 30 〜100 | |||||||

3 | CBR Breaking Strength /kN | ≧1.1 | ≧1.5 | ≧1.9 | ≧2.2 | ≧2.5 | ≧2.8 | ≧3 | ≧3.2 |

4 | Tearing Strength CD&MD kN | ≧0.15 | ≧0.25 | ≧0.32 | ≧0.4 | ≧0.48 | ≧0.56 | ≧0.62 | ≧0.7 |

5 | Resistant to Hydrostatic Pressure MPa | According to Table 2 | |||||||

6 | Peel Strength (N/cm) | ≧6 | |||||||

7 | Vertical Permeability Coeffcient (cm/s) | According to Design or Contract Requirement | |||||||

8 | Width Deviation % | -1.0 | |||||||

Item | Geomembrane Thickness (mm) | ||||||||

0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | ||

Resistant to Hydrostatic Pressure (Mpa)≧ | Geomembrane With One Side Geotextile | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.6 |

Geomembrane With Two Side Geotextile | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | |

1. Unit weight: 300g/㎡---1000g/㎡.

2. The width range is 3meter-6meters; Maximum width is 6meters; Other width can be custom.

3. The length can be 50, 100, 150meters or as request. Maximum length is depending on the rolling limit.

4. White color is most ordinary and popular color, other color can be custom.

Features of Composite Geomembrane:

· High tensile strength.

· Excellent chemical resistance.

· Effective drainage and waterproof performance.

· Excellent anti-seepage, anti-leakage, and moisture-proof performance.

· Excellent UV resistance.

· Excellent tear resistance and puncture resistance.

· Stable low-temperature embrittlement resistance.

· Easy to deploy.

· save costs.

· Anti-aging and anti-corrosion.

Applications of Composite Geomembranes:

Water Conservancy: Composite geomembranes are ideal for applications in water conservation, including anti-seepage, sealing, and reinforcement of dams, riverbanks, lakes, and reservoirs. They are also effective for canal lining, vertical core walls, and slope protection.

Environmental Protection & Sanitation: They are widely used in environmental projects such as landfills, sewage treatment plants, power plant conditioning pools, and the management of industrial and hospital waste.

Landscaping & Recreation: In landscaping, composite geomembranes are utilized in artificial lakes, rivers, reservoirs, golf course ponds, slope stabilization, and the creation of green lawns.

Municipal Engineering: They are commonly applied in municipal projects, including subways, underground building structures, green roofs, roof garden drainage, and sewage pipelines.

Mining & Waste Management: Composite geomembranes are used in mining applications such as washing tanks, heap leaching tanks, ash dumps, dissolution tanks, sedimentation tanks, and tailings pond liners to prevent seepage.

Petrochemical & Chemical Industries: These geomembranes are effective for petrochemical plants, refineries, oil storage tanks, chemical reaction tanks, secondary lining for sedimentation tanks, and other chemical containment systems.

Aquaculture: In aquaculture, composite geomembranes are used for intensive farming ponds, fish ponds, shrimp ponds, and sea cucumber farming, providing reliable slope protection and water containment.

Salt Industry: They are also used in the salt industry, including in crystallization ponds, brine pond covers, and salt production facilities, ensuring efficient sealing and protection.

Agriculture & Irrigation: Composite geomembranes are applied in agricultural fields, including reservoirs, drinking water storage pools, irrigation systems, and anti-seepage protection for agricultural ponds.

Transportation Infrastructure: They are used in transportation projects for reinforcing foundations in highways, and preventing seepage in culverts, contributing to the longevity of infrastructure.

Packaging & Delivery

We ensure secure packaging and efficient delivery to meet your project timelines. With ample spot inventory and strong production capacity, we guarantee fast shipments for all geosynthetic material orders. Our products are carefully packaged to prevent damage during transit, using industry-standard methods that maintain quality from factory to site.

About Us

Founded in 2012,Shandong Yibo Yangguang Engineering Materials Co.,Ltd has built a reputation among global leading Contractors as a trusted name in geosynthetics such as geotextiles,geomembrane liners,erosion control materials,and site management supplies.Products have been exported to Europe,the United States, Southeast Asia,Africa and other countries and regions.

The company has an advanced automatic Wide Geomembrane Production Line, Geomembrane Roughening Unit,Non-woven Equipment Production Line,Composite Membrane Production Line,Bentonite Waterproof Blanket Production Line,Polymer Self-adhesive Waterproofing Membrane Production Line and other more than ten production lines and a number of corresponding supporting equipment;It has high standardized production workshops and laboratories as well as functional areas such as storage centers,transfer centers and finished product warehouses.