Anti Permeation LLDPE Geomembrane

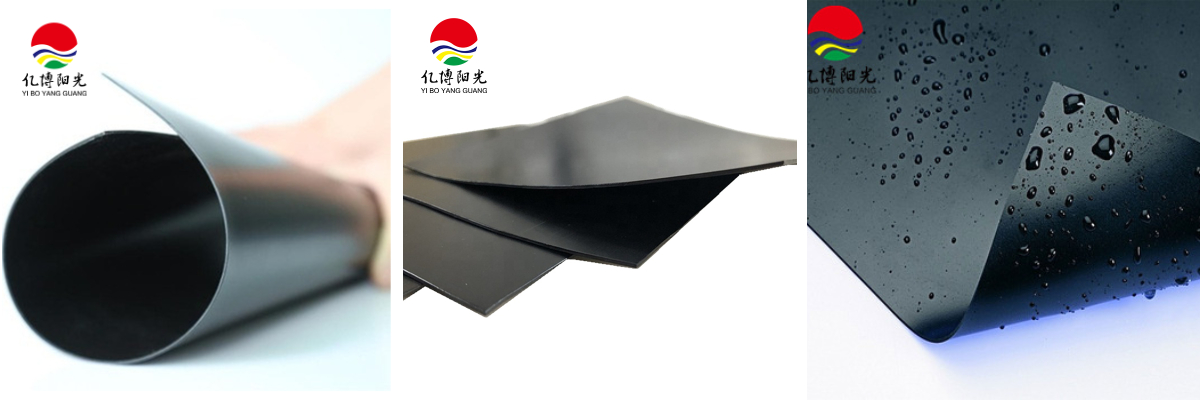

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

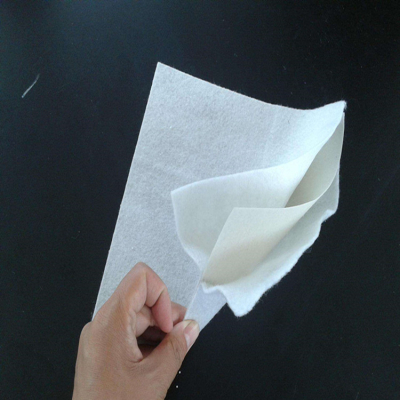

LLDPE (Linear Low-Density Polyethylene) is a specialized type of polyethylene characterized by a linear arrangement of polymer chains with occasional short branches. This molecular configuration enhances its mechanical properties, including superior tensile strength, exceptional flexibility, and high resistance to tearing. Compared to standard low-density polyethylene (LDPE), LLDPE exhibits a more densely packed molecular structure, granting it improved impact durability and greater resilience against environmental stress cracking caused by temperature fluctuations or chemical exposure.

Product Specifications

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Application Scenarios

LLDPE Geomembrane Application Specifications

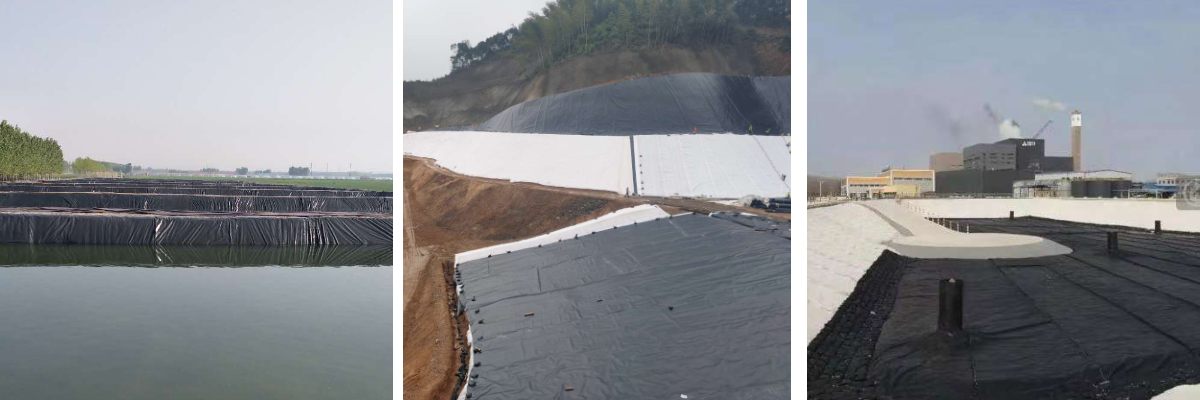

1. Environmental Engineering Applications

Sanitary Landfill Systems: Primary/secondary liner systems with leak detection

Waste Containment: Hazardous & non-hazardous waste storage facilities

Wastewater Treatment: Anaerobic lagoons and equalization basins

2. Water Resource Infrastructure

Hydraulic Structures:

Irrigation canals (≤1:1 slope applications)

Reservoir liners (≤30m water head)

Dam face sealing (textured surface variants)

Flood Control: Emergency water retention basins

3. Urban Development Projects

Decorative Water Features:

Ornamental ponds (0.5-1.0mm thickness)

Fountain basins (with root barrier protection)

Green Infrastructure: Rainwater harvesting systems

4. Transportation Engineering

Tunnel Waterproofing: Composite systems with geotextile backing

Subgrade Protection: Railway/highway embankment moisture barriers

Drainage Systems: Combined with geocomposite drains

5. Agricultural Water Management

Water Storage:

Irrigation ponds (UV-stabilized formulations)

Aqueduct liners (high-abrasion resistance)

Packaging & Delivery

We ensure secure packaging and efficient delivery to meet your project timelines. With ample spot inventory and strong production capacity, we guarantee fast shipments for all geosynthetic material orders. Our products are carefully packaged to prevent damage during transit, using industry-standard methods that maintain quality from factory to site.

Key advantages:

Fast Delivery: Immediate dispatch available for in-stock items

Reliable Logistics: Coordinated shipping solutions for domestic and international orders

Quality Packaging: Protective wrapping tailored to product specifications

Custom Options: Special packaging available upon request

Our 24/7 service team tracks shipments and provides real-time updates, ensuring your materials arrive on schedule. Construction-grade materials are delivered ready for immediate installation, supported by our end-to-end supply chain management.

*"Your business, we guarantee" - from packaging to final delivery.*

About Us

We are specialized in the development, manufacturing, sales, and construction of geomaterials and their supporting products, specializing in the production of: HDPE geomembrane, Rough geomembrane, Composite geomembrane, EVA waterproof board, Polymer self-adhesive waterproof board, Bentonite waterproof blanket, Filament (short silk) geotextile, Composite drainage net and other geomaterials products.

Our Company Services

Technical Specifications for Engineered Geomembrane Solutions

Product Portfolio

We manufacture precision-grade geomembranes in three surface configurations:

Standard Smooth (0.25-3.0mm thickness range)

Textured Surface (co-extruded/embossed, 0.5-3.5mm)

Column-Point Reinforced (structured, 1.0-4.0mm)

Virtual Quality Assurance Program

Digital factory walkthroughs via 360° VR technology

Sample kits with ASTM-certified test reports

Material data sheets compliant with:

GRI-GM13 standards

ISO 9001:2015 quality systems

NSF/ANSI 61 for potable water

Performance Guarantees

Extended Service Life

Minimum 4-year warranty (accelerated aging tested per ASTM D7238)

Field-proven 8-10 year performance in extreme environments

Advanced Material Science

100% virgin resin formulation with:

2.5% carbon black (UV stabilization)

High-performance antioxidant package (HP-OIT ≥100 min)

Multi-axial reinforcement (≥40N puncture resistance)

Manufacturing Excellence

Blown-film extrusion process (ASTM D5199 compliant)

Continuous thickness monitoring (±0.02mm tolerance)

Blockchain-tracked production batches