Chemical Resistant LLDPE Geomembrane

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

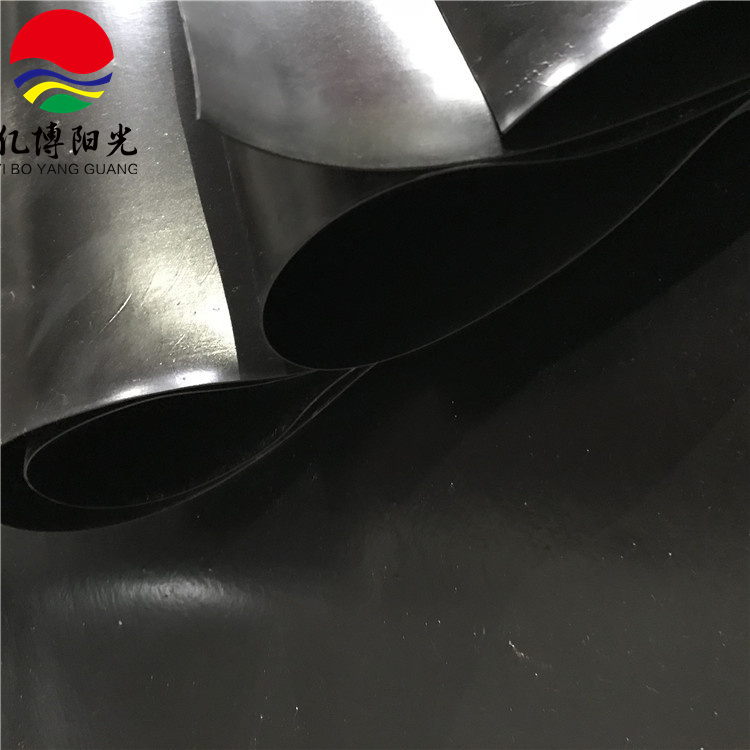

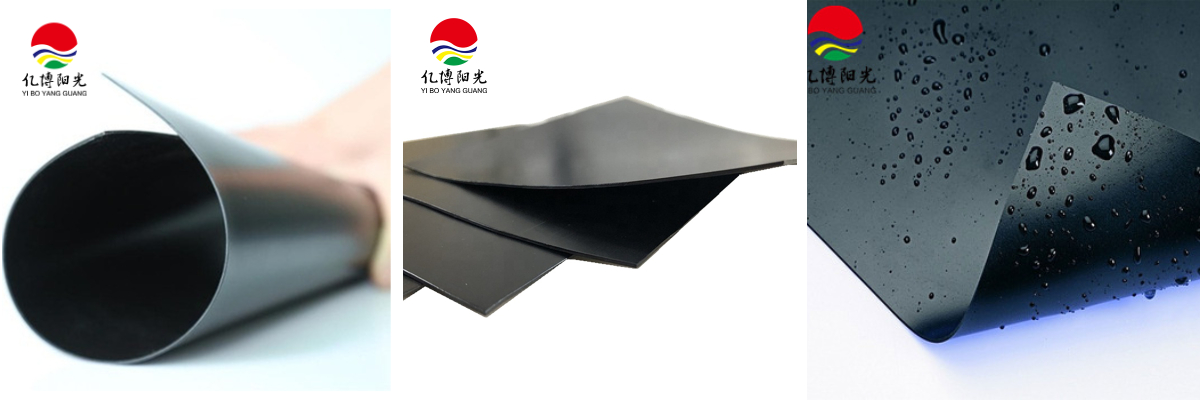

LLDPE geomembrane, a linear low-density polyethylene-based impermeable material, finds extensive applications in civil, hydraulic, and environmental engineering. It exhibits strong resistance to chemical corrosion (including acids, alkalis, and salts) and retains flexibility even at extremely low temperatures (-50°C), making it suitable for cold climates. However, its UV resistance is limited (requiring stabilizers for prolonged outdoor use), and its low density (0.915–0.940 g/cm³) ensures lightweight and easy installation.

Product Specifications

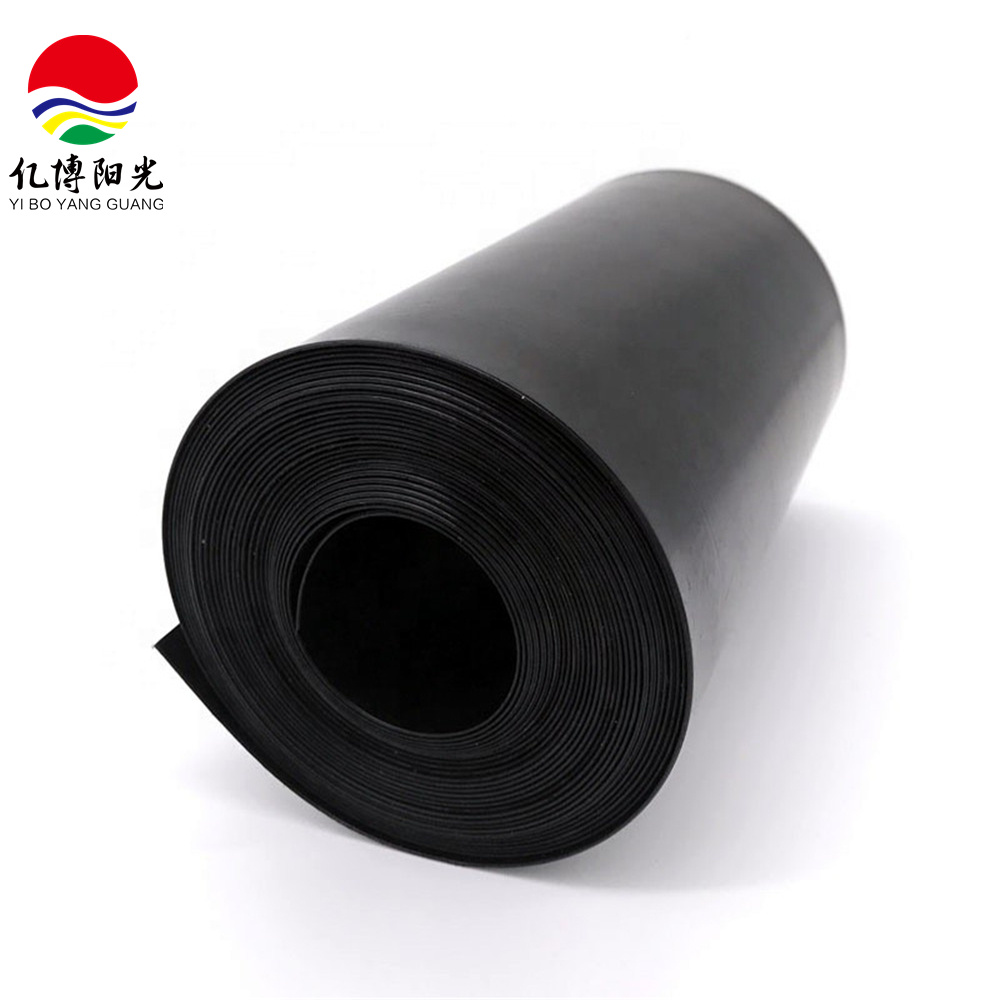

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Application Scenarios

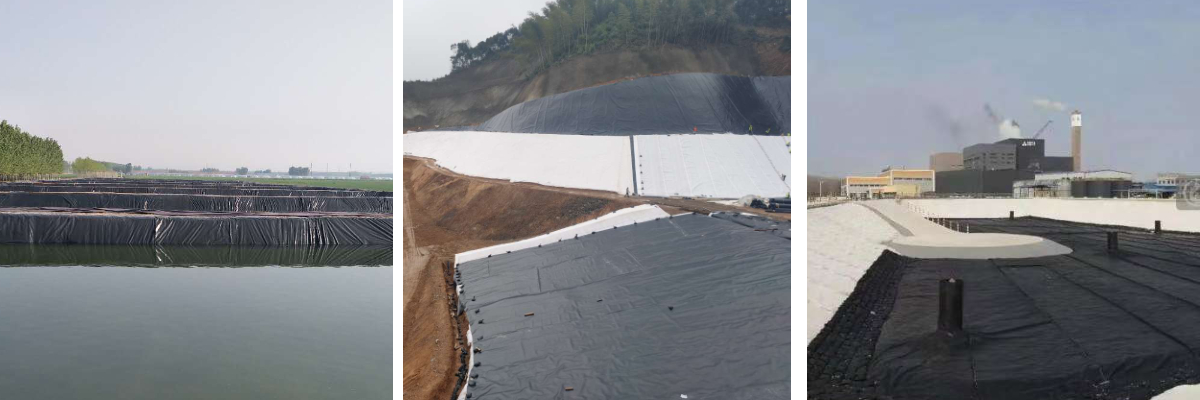

Landfill Applications

Landfill liners – Acts as an impermeable barrier to block leachate from contaminating groundwater.

Waste containment – Prevents harmful landfill seepage from polluting underground water sources.

Reservoir Anti-Seepage

Reservoir lining – Used as a waterproofing layer on reservoir bases and dams to minimize water loss.

Water conservation – Reduces seepage in reservoirs, ensuring efficient water storage and supply.

Aquaculture Ponds

Pond liners – Prevents water leakage, maintaining optimal water levels and quality for aquaculture.

Fish farming – Ensures water retention and stable conditions for aquatic life.

Irrigation Ponds

Water storage – Helps retain rainwater and irrigation water while reducing evaporation losses.

Agricultural use – Enhances water conservation in farming by preventing seepage in storage ponds.

Packaging & Delivery

We provide high-performance geosynthetics backed by a resilient supply chain. Our strategically located warehouses enable rapid bulk supply, while AI-optimized production ensures on-time delivery—even for large-scale orders. Every shipment is protected with advanced cushioning and moisture barriers, monitored via real-time tracking to prevent delays.

Rigorous ISO 9001-certified processes and automated QA systems guarantee flawless material integrity. Our just-in-time logistics reduce lead times while upholding strict safety standards, keeping your projects on schedule.

Key Benefits:

Same-Day Dispatch – Pre-stocked inventory & automated WMS for urgent needs.

Global Delivery Network – Air, sea, and rail logistics with pre-cleared customs.

Smart Packaging – ASTM-compliant, project-specific protection (moisture barriers, crush-proof crates).

Adaptable Solutions – Customizable packing (cushioning, strapping) for hazardous or sensitive environments.

Live IoT sensors (shock, humidity, temperature) provide 24/7 shipment visibility via client dashboards. Materials arrive installation-ready, with full traceability from factory to site.

About Us

Shandong Yibo Yangguang Engineering Materials Co., Ltd. is affiliated to Boda Construction Group. The company is located in Laiwu High-tech Zone, Jinan City, Shandong Province. It is a high-tech enterprise specializing in the research and development, manufacturing, sales and construction of geotechnical materials and related products including HDPE geomembrane, textured geomembrane, filament ( staple fiber ) geotextilecomposite geomembrane, EVA waterproof board, polymer self-adhesive waterproof board, bentonite waterproof blanket, composite drainage net and other geotechnical materials products.

Our Company Services

As pioneers in geomembrane engineering, we design and manufacture high-performance barrier systems tailored to demanding containment applications. Our expertise spans:

Engineered Liner Solutions

Smooth Geomembranes – ASTM D4439 Class I-III compliant, reinforced with weldable polypropylene scrim for superior seam integrity.

Textured Geomembranes – 3D-embossed surface (Ra 150–500 μm) for optimal slope stability and interface friction.

Column-Point Geomembranes – Precision-perforated arrays (Φ5–20mm) for integrated drainage in composite systems.

Customization Capabilities

Variable Thickness – 0.5–3.0mm tailored to project specifications.

Specialty Coatings – Antimicrobial (silver-ion) or flame-retardant formulations for enhanced performance.

Competitive Advantages

Extended Durability – 40+ year service life under standard conditions.

Premium Material Quality – Virgin HDPE base with carbon black, UV stabilizers, and antioxidants for exceptional tensile strength (≥25 MPa) and puncture resistance (≥500 N).

Technical Excellence – In-house laboratory with ASTM-compliant testing and QA team for batch-to-batch consistency.

Leakproof Guarantee – Blow-molded HDPE/EVA liners with <1×10⁻¹² cm/sec permeability to liquids/gases.

End-to-End Project Support

• 24/7 engineering consultation

• Certified installation crews

• Onsite workforce training

• Pre-deployment material inspection

• Complimentary replacement components

• No-hassle warranty replacements