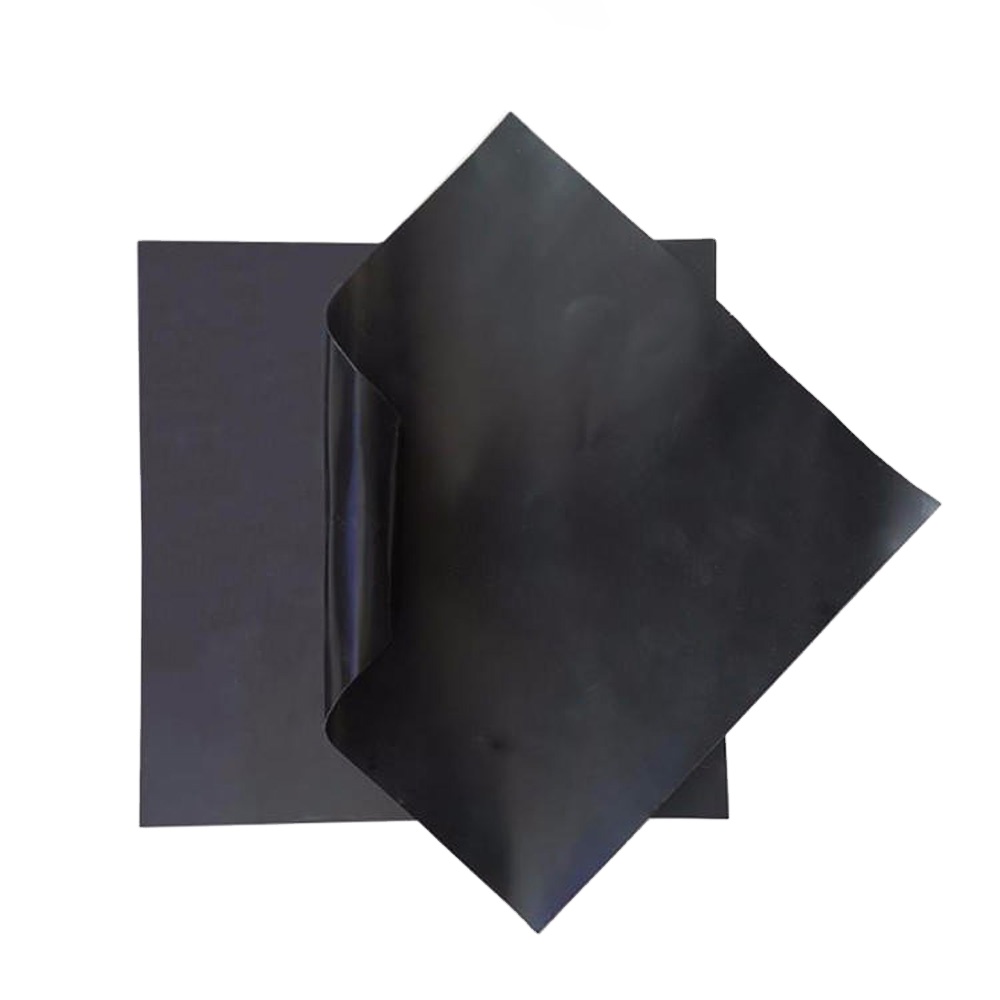

High Density LLDPE Geomembrane

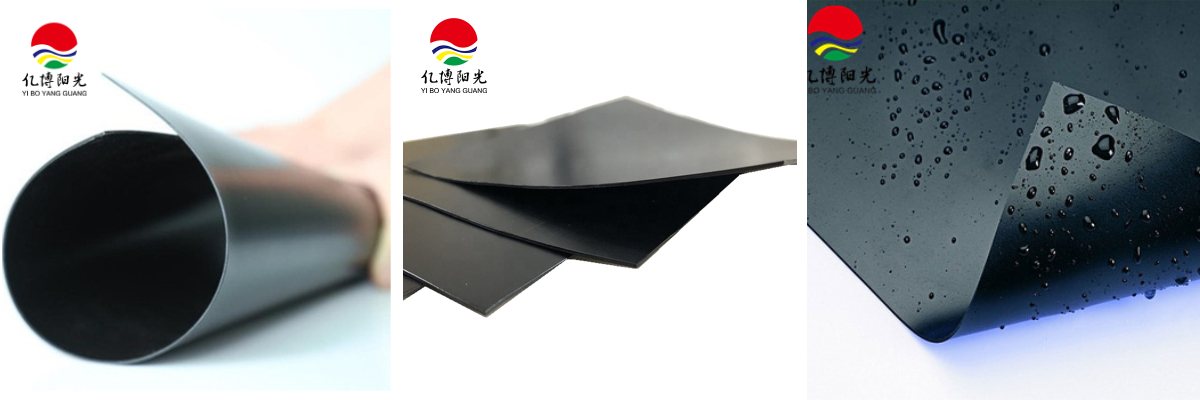

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

LLDPE (Linear Low-Density Polyethylene) is an engineered polyethylene derivative defined by a linear polymer backbone with sporadic short-chain branching. This structural design strengthens its mechanical performance, delivering excellent tensile strength, remarkable flexibility, and outstanding resistance to tearing. In contrast to conventional LDPE, LLDPE features a tightly packed molecular configuration, which enhances its impact durability and elevates its ability to withstand environmental stress cracking induced by thermal cycling or chemical interactions.

Product Specifications

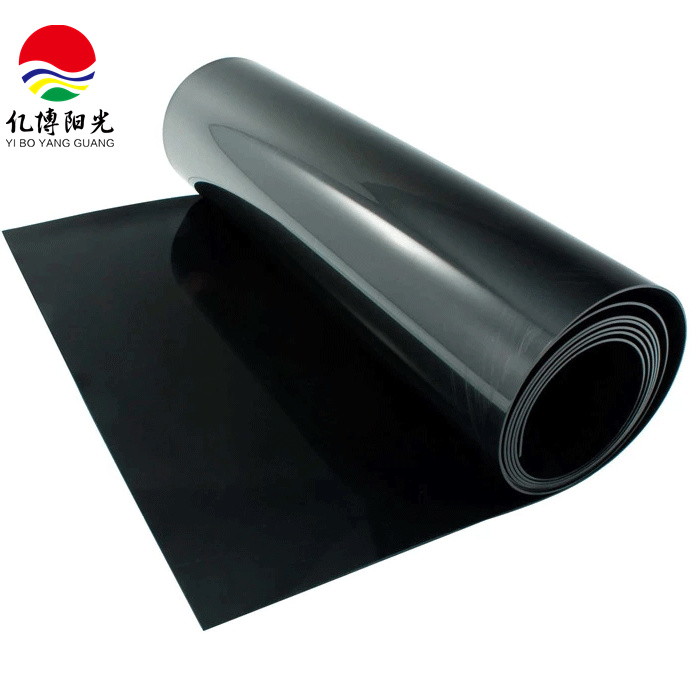

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

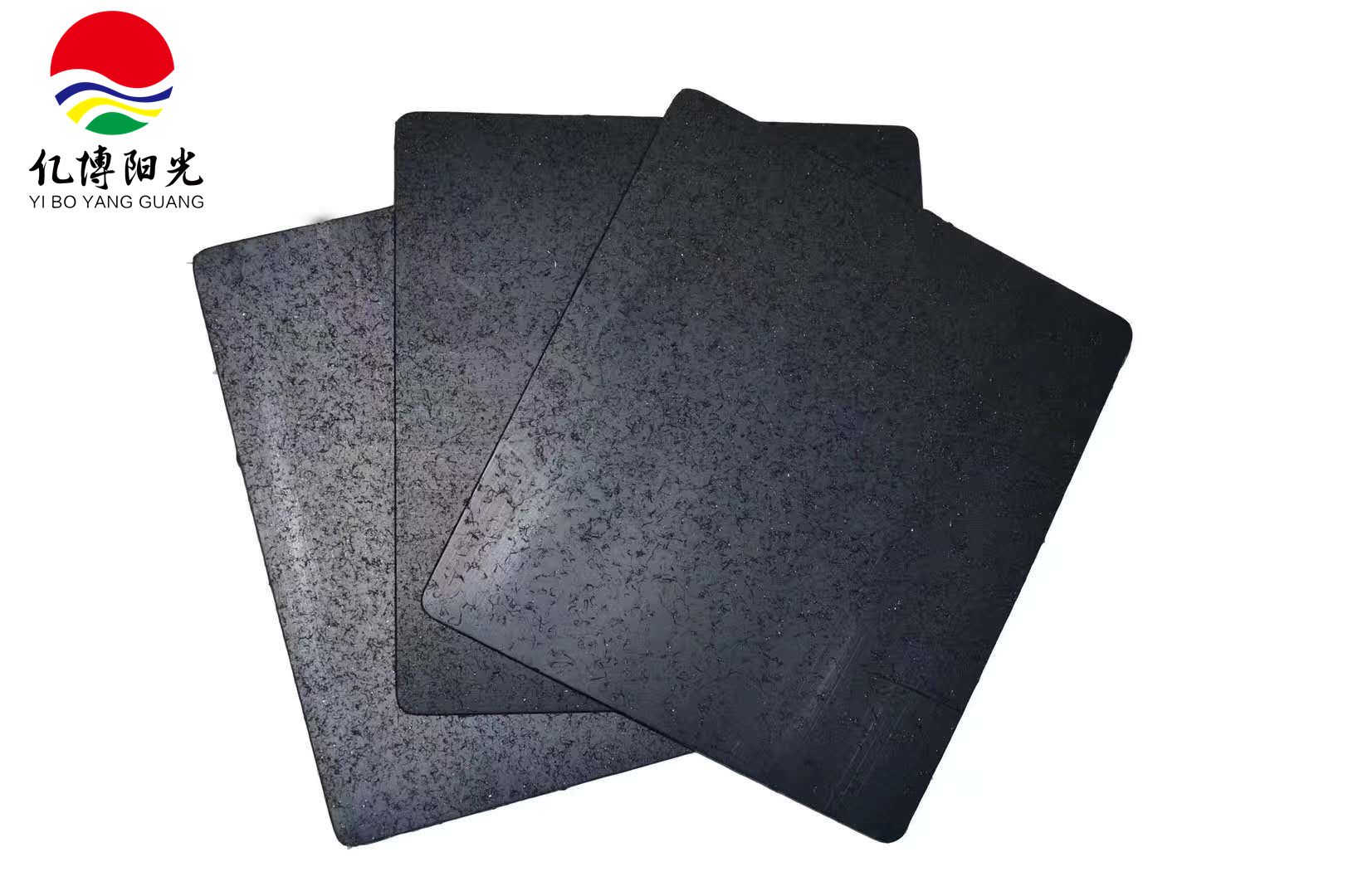

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

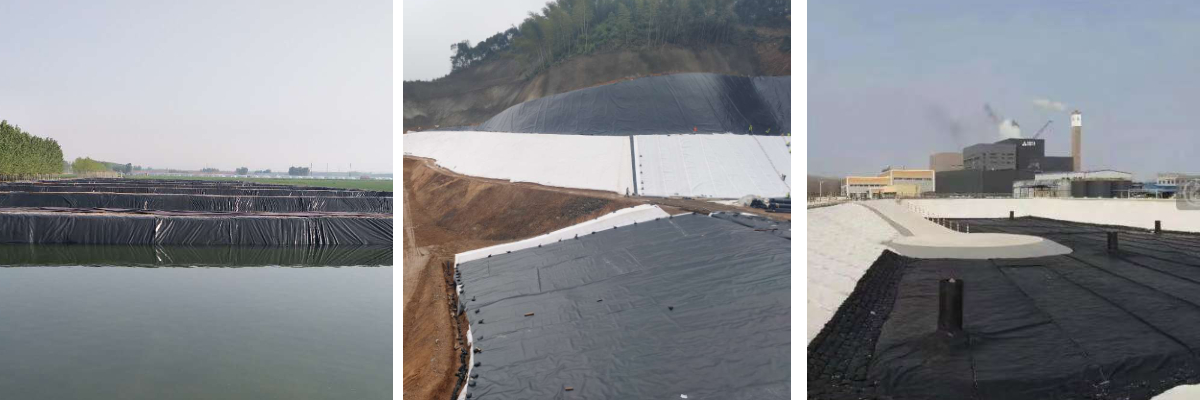

Application Scenarios

Reservoir Lining Systems

Primary Application: Dual-phase fluid retention technology for simultaneous evaporation suppression (up to 85% reduction) and seepage control (hydraulic conductivity <1×10⁻¹³ cm/s).

Engineering Benefits:

Ultra-lightweight deployment (1.5-3.0 kg/m²) enables rapid installation over complex topographies

Custom-formulated 1.0mm LLDPE membrane with:

High-temperature stabilizers (continuous 50°C service)

UV-resistant carbon black masterbatch

Demonstrated 10-year field performance in Middle Eastern climates

Precision Irrigation Channel Liners

Hydraulic Optimization: Achieves 95% water conveyance efficiency through:

Continuous thermal-fusion welded seams (ASTM D6392 compliant)

Terrain-conforming flexibility (up to 700% elongation)

Modular installation for channels up to 20m width

Fluvial Erosion Control Systems

Bank Stabilization Technology:

Composite membrane-geotextile assembly provides:

Shear strength >25 kN/m (ASTM D5321)

Filtration efficiency meeting EN ISO 12958

Verified performance in Yangtze River applications:

40% reduction in sediment loss

Withstands 5 m/s flow velocities

Packaging & Delivery

Advanced Logistics & Packaging Solutions for Geosynthetics

Smart Packaging System

Our engineered packaging solution exceeds international shipping requirements through:

Triple-layer protective wrapping meeting ASTM D4169 DC-15 standards

Military-specification cushioning materials with impact-resistant edges

Integrated humidity control (silica gel + moisture barrier film)

IoT-enabled monitoring devices tracking:

Real-time vibration (ISTA 3A compliant)

Temperature fluctuations (±1°C accuracy)

Humidity levels (0-100% RH range)

Supply Chain Optimization

Strategic Inventory Network:

10,000+ MT capacity across 3 regional distribution centers

Automated warehouse management (WMS) with <2hr order processing

Flexible Manufacturing:

Rapid product changeover capability (≤20min)

Priority production scheduling for emergency orders

Value-Added Services

Proactive Shipment Protection:

AI-driven risk forecasting (weather/route analysis)

24/7 monitoring center with instant alert system

98% on-time delivery performance guarantee

Jobsite-Ready Delivery:

RFID-enabled material tracking

BIM-integrated logistics coordination

Pre-sorted installation kits available

Quality Assurance:

Digital twin technology for shipment simulation

92% predictive accuracy for delivery conditions

Post-delivery performance analytics reporting

About Us

We are a vertically integrated manufacturer and engineering contractor specializing in advanced geosynthetic systems. Our core competencies encompass:

Material Development & Production

High-performance geomembranes:

Standard HDPE (0.75-3.0mm)

Textured surface variants (co-extruded/embossed)

Multi-layer composites (with geotextile backing)

Waterproofing Systems

EVA copolymer sheeting (flexible membrane roofing)

Pre-applied polymer-bonded membranes

Sodium bentonite geosynthetic clay liners (GCL)

Geocomposite Products

High-strength geotextiles:

Continuous filament woven

Needle-punched nonwoven

Three-dimensional drainage composites

All-in-one drainage/barrier systems

Our Company Services

Technical Specifications for Engineered Geomembrane Solutions

Product Portfolio

We manufacture precision-grade geomembranes in three surface configurations:

Standard Smooth (0.25-3.0mm thickness range)

Textured Surface (co-extruded/embossed, 0.5-3.5mm)

Column-Point Reinforced (structured, 1.0-4.0mm)

Virtual Quality Assurance Program

Digital factory walkthroughs via 360° VR technology

Sample kits with ASTM-certified test reports

Material data sheets compliant with:

GRI-GM13 standards

ISO 9001:2015 quality systems

NSF/ANSI 61 for potable water

Performance Guarantees

Extended Service Life

Minimum 4-year warranty (accelerated aging tested per ASTM D7238)

Field-proven 8-10 year performance in extreme environments

Advanced Material Science

100% virgin resin formulation with:

2.5% carbon black (UV stabilization)

High-performance antioxidant package (HP-OIT ≥100 min)

Multi-axial reinforcement (≥40N puncture resistance)

Manufacturing Excellence

Blown-film extrusion process (ASTM D5199 compliant)

Continuous thickness monitoring (±0.02mm tolerance)

Blockchain-tracked production batches