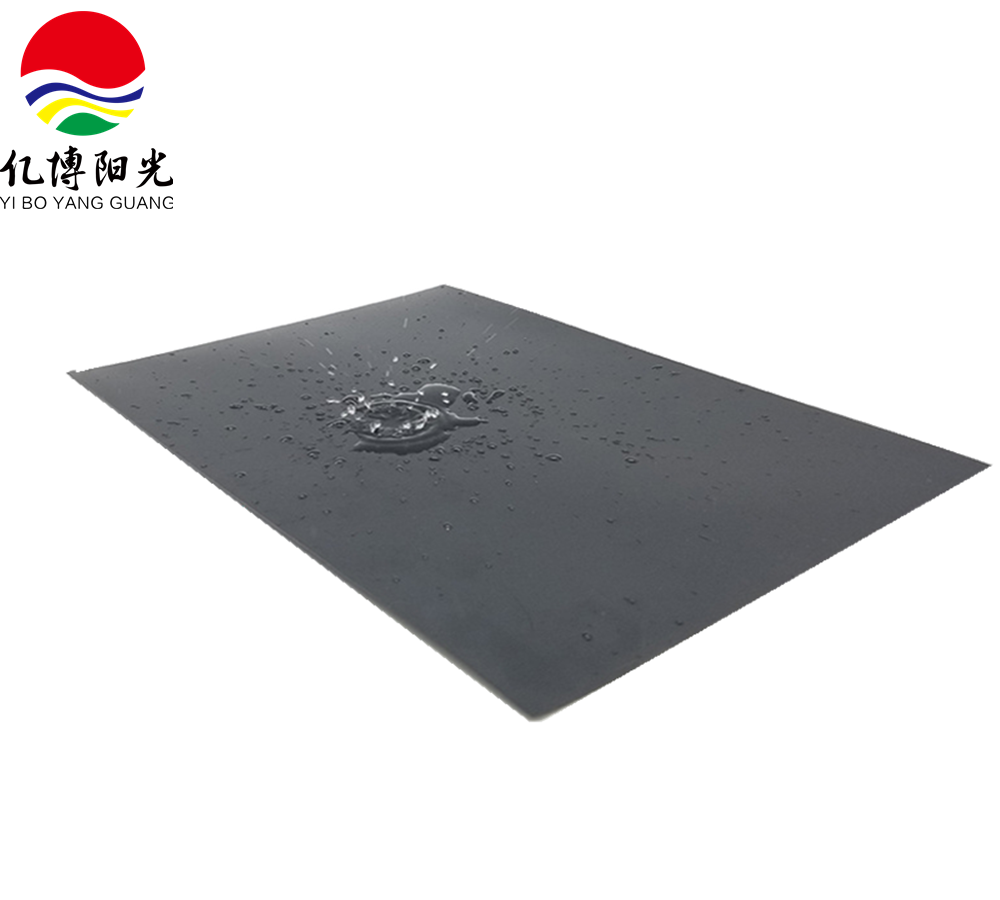

Antistatic LLDPE Geomembrane

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

LLDPE geomembrane (linear low-density polyethylene geomembrane) is a waterproof and anti-seepage material made from linear low-density polyethylene (LLDPE), and is widely used in environmental protection, water conservancy, municipal, agricultural and other fields. The following are its key features and applications:

Material properties

LLDPE resin: It is copolymerized from ethylene and a small amount of α -olefins (such as butene and hexene), with a linear molecular chain structure. It combines flexibility and high mechanical strength.

Performance advantages:

Strong puncture resistance: It is more resistant to being pierced by sharp objects than ordinary LDPE (low-density polyethylene).

Good ductility: High elongation at break, adaptable to foundation deformation.

Chemical stability: Resistant to acids, alkalis, salts, oils and most organic solvents.

Low-temperature adaptability: Maintains flexibility in low-temperature environments (-60℃ to 60℃).

Environmentally friendly and non-toxic: Complies with drinking water and soil protection standards.

Product Specifications

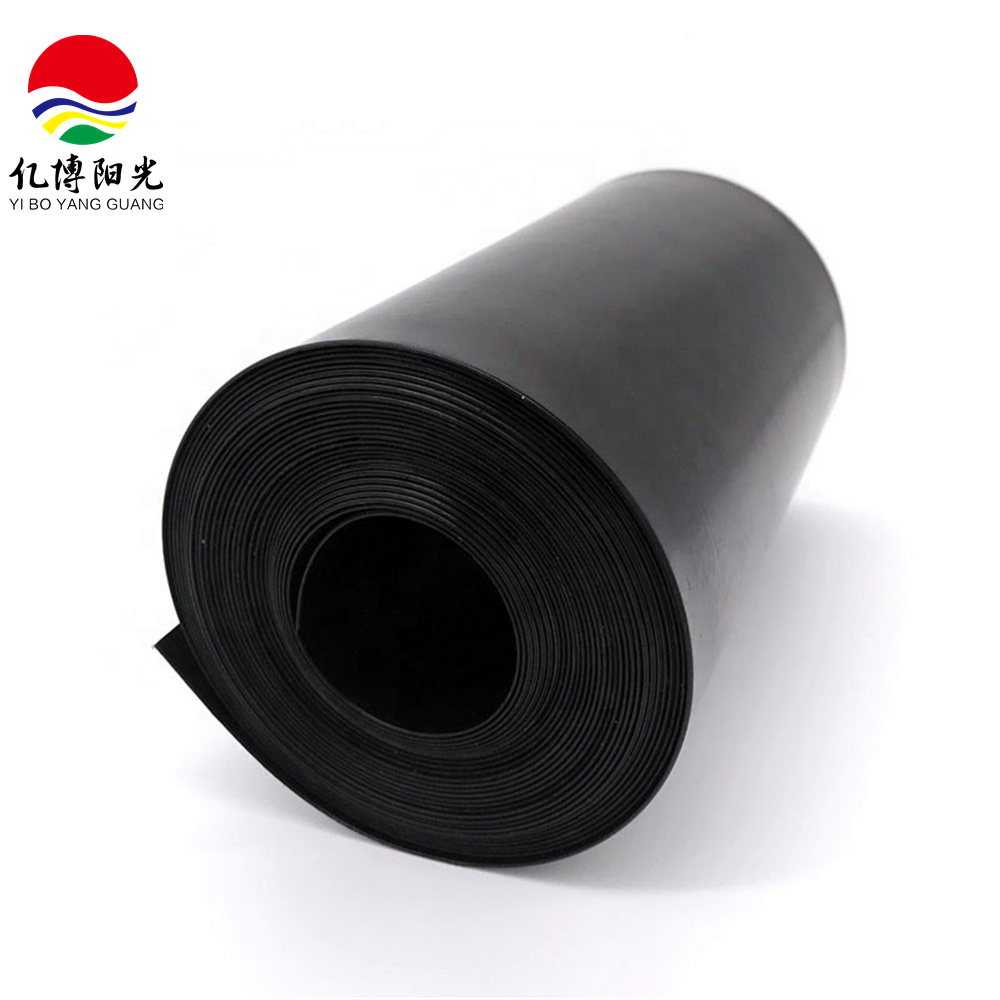

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

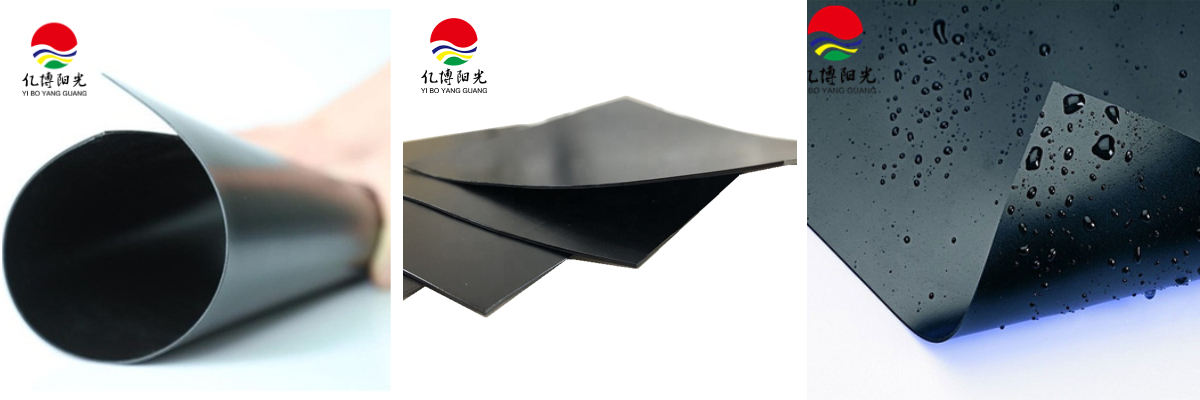

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

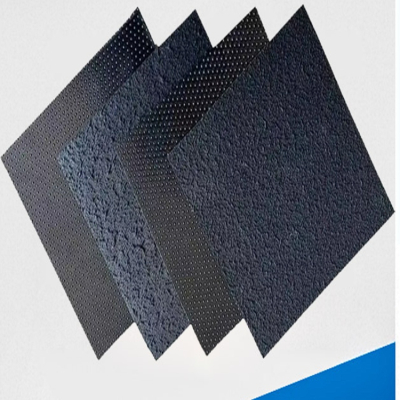

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Application Scenarios

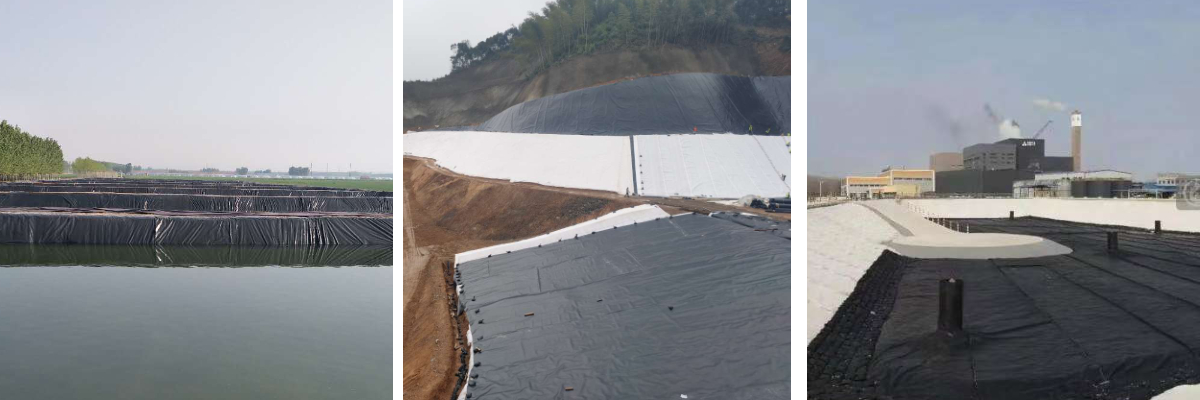

LLDPE Geomembrane Applications in Water Conservancy Projects

1. Reservoir Anti-Seepage

Primary Function: Minimizes water loss through evaporation and seepage, ensuring efficient water storage.

Key Benefits:

Lightweight & Flexible: Easy to install over expansive or irregular surfaces (e.g., artificial lakes, irrigation ponds).

Durability: Resists UV degradation and thermal expansion, even in extreme climates.

Case Example: A Middle Eastern desert reservoir utilized 1.0mm LLDPE geomembrane, maintaining structural integrity after 10 years at 50°C+ with no signs of cracking or aging.

2. Irrigation Channel Seepage Control

Primary Function: Prevents water leakage, improving irrigation efficiency and conserving resources.

Key Benefits:

Easy Welding & Installation: Can be seamlessly spliced along channel lengths.

Terrain Adaptability: Conforms to uneven surfaces without rupturing.

3. Riverbank & Channel Rehabilitation

Primary Function: Stabilizes permeable riverbeds and reduces soil erosion.

Key Benefits:

Composite Reinforcement: When paired with geotextiles, enhances scour resistance and prolongs service life.

Case Example: A Yangtze River slope protection project combined LLDPE geomembrane with geotextile, significantly improving erosion resistance and long-term stability.

Packaging & Delivery

Professional/Business Tone:

"Rest assured, your geosynthetic materials will arrive safely and on schedule. We maintain substantial inventory reserves and robust manufacturing output to facilitate rapid order fulfillment. All shipments are meticulously packaged using proven protective methods to preserve product integrity throughout transit.

Core Delivery Benefits:

Same-day processing for stock items

Optimized freight solutions (domestic & global)

Damage-resistant packaging protocols

Custom crating/palletization services

Our dedicated logistics team monitors every shipment 24/7, providing live tracking updates. Materials arrive jobsite-ready, backed by our fully integrated supply network."

Concise/Bullet-Point Format:

"Guaranteed Delivery You Can Trust:

Secure, industry-approved packaging

Fast shipping from stocked inventory

Domestic/global logistics expertise

Real-time shipment tracking

Installation-ready materials

Custom packaging solutions

Our production capacity and inventory ensure timely delivery, while our protective packaging safeguards your order en route. 24/7 logistics support included."

About Us

We are a leading manufacturer and supplier of geosynthetic materials, offering comprehensive solutions from production to installation. Our product portfolio includes:

HDPE Geomembranes (Smooth & Textured)

Composite Geomembranes

EVA Waterproof Panels

Self-Adhesive Polymer Waterproofing Sheets

Bentonite Waterproof Blankets (GCL)

Woven & Nonwoven Geotextiles (Filament & Short Fiber)

3D Drainage Nets

With expertise in R&D, manufacturing, and project implementation, we deliver high-performance geosynthetic solutions for civil, environmental, and hydraulic engineering.

Our Company Services

Advanced Geomembrane Manufacturing & Custom Solutions

We engineer precision-grade geomembranes in three surface configurations:

Smooth Finish (Standard)

Textured/Structured (Enhanced Friction)

Column-Point Pattern (High Shear Resistance)

Request a Virtual Factory Tour & Material Samples

1. Extended Durability

≥4-year service life certification (ASTM D7238 accelerated aging tests)

2. Premium Material Composition

100% virgin HDPE resin with:

2.5% carbon black dispersion (UV stabilization)Antioxidant masterbatch (HALS-based)

Multi-axial reinforcement for >40N puncture resistance (ASTM D4833)

3. Quality Assurance Protocol

In-line thickness gauging (Laser micrometers)

Destructive testing per ASTM D6392 (Tensile) / D5884 (Stress Crack Resistance)

4. Impermeability Performance

Blown-film process achieves <1×10⁻¹³ cm/sec hydraulic conductivity

Dual-material options:

HDPE (0.94-0.96g/cm³ density)

EVA (Ethylene-Vinyl Acetate copolymer)