Reservoir Seepage Control Use Composite Geomembrane

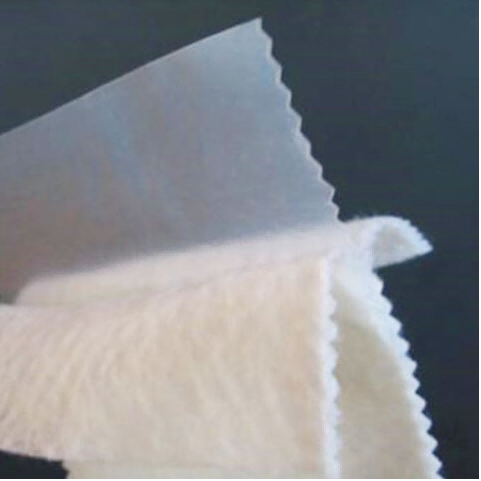

Composite Geomembrane (Geotextile-Geomembrane Composite) is created by heat-bonding a nonwoven geotextile layer to a geomembrane. This composite combines the benefits and features of both materials. The geotextile enhances the system by offering better puncture resistance, tear propagation control, and improved frictional properties, which help reduce sliding. Additionally, the geotextile itself contributes tensile strength to the overall structure.

Composite Geomembrane Specifcations

The composite geomembrane liner has the advantages of geomembrane and geotextile at the same time. Geomembranes provide excellent seepage, leak, moisture, tear, and puncture resistance. The geotextile layer increases the tensile strength, and the composite geomembrane lining plays a great role in the landfill.

On the basis of HDPE geomembrane, the composite geomembrane liner has both flexibility and ductility to improve the waterproof and seepage resistance.

The composite geomembrane is thermally bonded by non-woven or woven geotextile and HDPE geomembrane through calendering technology. Composite geomembrane and geomembrane have the advantages of geomembrane and geotextile at the same time. It not only maintains the waterproof, anti-seepage, and tear resistance of the geomembrane while maintaining the characteristics of the geotextile but also protects the geomembrane.

Technical Parameters | Unit weight g/㎡ | |||||||

400 | 500 | 600 | 700 | 800 | 900 | 1000 | ||

Thickness of PE Membrane mm | 0.2-0.35 | 0.3-0.6 | ||||||

Common Spec. | one geotextile plus one geomembrane | 150/0.25 | 200/0.3 | 300/0.3 | 300/0.4 | 300/0.5 | 400/0.5 | 400/0.6 |

two geotextile plus one geomembrane | 100/0.2/100 | 100/0.3/100 | 150/0.3/150 | 200/0.3/200 | 200/0.4/200 | 200/0.5/200 | 250/0.5/250 | |

Unit area weight deviation % | -10 | |||||||

Breaking Strength KN/M≥ | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | |

Breaking elongation % | 30-100 | |||||||

Tear Strength KN | 0.15 | 0.25 | 0.32 | 0.4 | 0.48 | 0.56 | 0.62 | |

CBR bursting strength KN≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3 | |

Vertical seepage coefficient cm/s | 10--12 | |||||||

Resist Hydraulic pressure MPa≥ | 0.4-0.6 | 0.6-0.1 | ||||||

Features of Composite Geomembrane:

High tensile strength.

Anti-aging and anti-corrosion.

Excellent chemical resistance.

Effective drainage and waterproof performance.

Excellent impermeable, leak and moisture proof.

Excellent UV resistance.

Excellent tear and puncture resistance.

Stable low temperature embrittlement resistance.

Easy to deploy.

Cost saving.

Applications of Composite Geomembranes:

Composite geomembrane is also used in Salt industry , agriculture, reservoirs, drinking water pools, storage ponds, fish ponds, lining of shrimp ponds, sea cucumber circle slope protection,and anti-seepage irrigation systems. chemical plants, refineries, oil storage tanks, seepage prevention, chemical reaction tanks, sedimentation tank linings, secondary linings,landfills, sewage treatment plants, power plant conditioning pools, industrial, hospital solid waste,dams of rivers, lakes, and reservoirs, anti-seepage of canals, vertical core walls, slope protection, etc.

About Us

Shandong Yibo Yangguang Engineeing Materials Co.,Ltd, is located in Jinan city, Shandong province. It is an environmental protection technology global service provider integrating geotechnical material research and development, production, sales, construction and maintenance. It specializes in the production of geomembranes, textured surface geomembranes, EVA waterproof boards, geotextiles, composite geomembranes, geocomposite drainage nets (6m), GCL , cement blankets, PVC coated tarpaulin, ton bags and other geotechnical materials products. It has construction qualifications such as municipal administration, environmental protection, water conservancy and hydropower, and provides professional and comprehensive solutions for waterproofing and anti-seepage in tailings ponds, heap leaching sites, landfills, water conservancy projects, slag dams, mining chemicals, transportation tunnels, agriculture, animal husbandry and fishery. At the same time, the company's products are also exported to more than 30 countries and regions including Central Asia, Southeast Asia, Africa and South America.