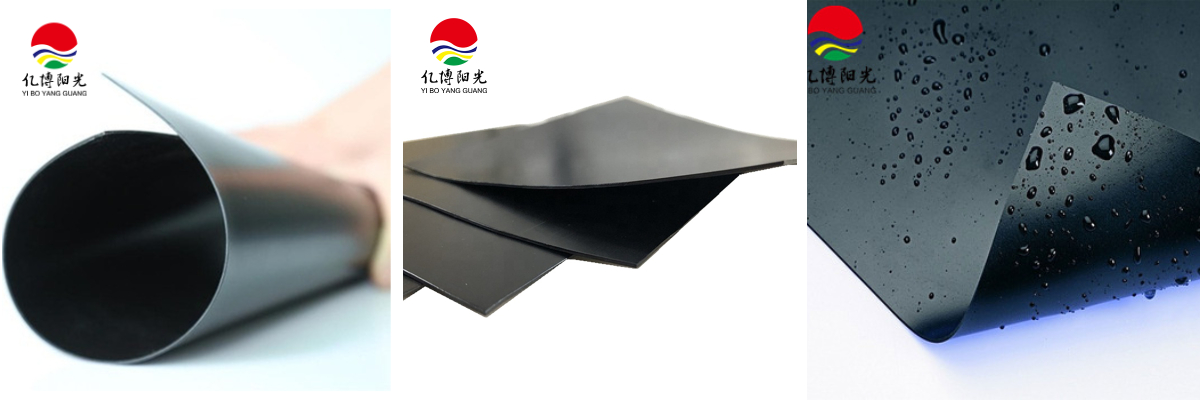

HDPE Geomembrane

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

Premium-grade high-density polyethylene (HDPE) geomembranes are produced using state-of-the-art extrusion technology. This method guarantees consistent thickness distribution, exceptional tensile resilience, and superior adaptability. Engineered for prolonged durability, these smooth HDPE geomembranes exhibit unmatched resistance to chemical degradation, ultraviolet radiation, and environmental stress, serving as optimal containment solutions for diverse geoenvironmental and civil engineering applications.

Product Specifcations

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

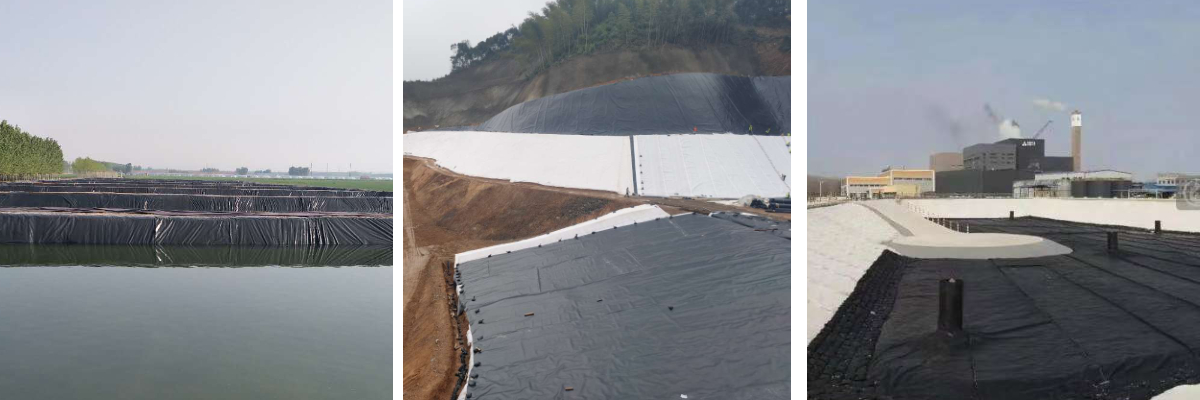

Application Scenarios

Urban Environmental Protection: Critical for landfill caps, wastewater treatment facilities, and hazardous waste containment systems.

Hydraulic Engineering: Essential in irrigation canals, water retention basins, and flood control infrastructure.

Recreational Water Features: Perfect for decorative fountains, artificial wetlands, and urban aquatic landscapes.

Transport Networks: Utilized in roadway subgrade protection, tunnel waterproofing, and railway drainage layers.

Agricultural Infrastructure: Deployed in livestock lagoons, crop irrigation reservoirs, and agricultural runoff management.

Aquatic Farming Systems: Ensures water integrity in commercial fish breeding tanks and marine culture enclosures.

Modular Construction: Provides leak-proof barriers for prefabricated containment units and mobile environmental solutions.

Packaging & Delivery

Robust protective measures ensure secure transit and timely project execution. Leveraging substantial inventory reserves and streamlined production, we expedite geosynthetic shipments globally. Specialized packaging protocols safeguard product integrity during transportation, adhering to international material handling standards.

Key Benefits:

Rapid Turnaround: Priority dispatch for stock items

Global Logistics Network: Tailored shipping solutions across 50+ countries

Customized Crating: Product-specific protective layering

Special Handling: Vacuum-sealed options for sensitive environments

Our dedicated logistics team provides 24/7 shipment monitoring with GPS-tracked updates. Project-ready materials arrive pre-inspected, backed by comprehensive supply chain oversight.

"Precision packaging meets global delivery excellence."

About Us

As a vertically integrated manufacturer of geosynthetic solutions, we specialize in the innovation, production, and technical implementation of: HDPE geomembranes (smooth/textured), EVA waterproof panels, polymer-modified adhesive membranes, sodium bentonite composites, woven/nonwoven geotextiles, and 3D drainage networks.

Our Company Services

Custom fabrication of geomembrane systems including smooth, textured, and hybrid surface configurations. Virtual facility tours and product sampling available upon request.

Competitive Advantages:

Extended Durability: 5+ year performance warranties

Quality Assurance: ISO-certified laboratories with automated thickness monitoring systems

Engineered Performance: Triple-layer co-extrusion technology ensures 0.08mm tolerance control

Value-Added Services:

Remote Technical Consultation

Certified Installation Crew Deployment

Onsite Welding Certification Programs

Pre-Shipment Quality Verification

Complementary Maintenance Kits

Defect Replacement Commitment