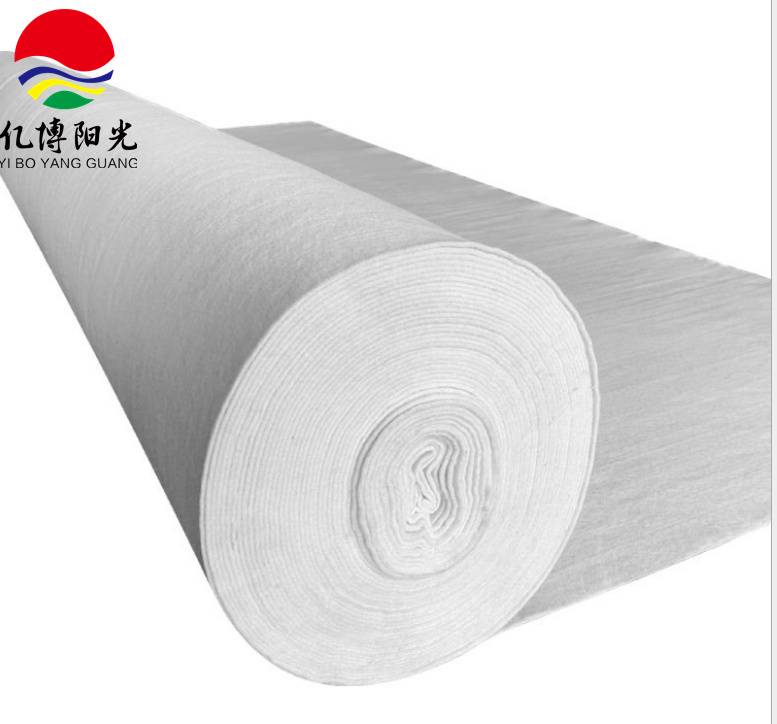

200m2 Geotextile Fabric for Ponds

High Chemical Resistance: Durable against acids, alkalis, and other chemicals.

UV & Weather Resistant: Reliable performance in outdoor conditions.

Superior Puncture Resistance: Withstands heavy loads and sharp objects.

Excellent Filtration & Drainage: Prevents soil migration while allowing water flow.

Flexible Installation: Easy to cut, weld, and lay on-site.

Cost-Effective: Long service life with minimal maintenance.

Product Introduction

A 200m² Geotextile Fabric for Ponds refers to a roll of permeable synthetic textile with a total coverage area of 200 square meters, specifically engineered for the construction, protection, and maintenance of ponds. It is typically installed beneath a waterproof geomembrane (like an HDPE liner) or in certain filtration layers to ensure the pond's long-term stability and functionality.

Product Specifications

| Material | 100% Polyester (PET) Staple Fiber |

| Fabric Type | Needle-Punched Nonwoven Geotextile |

| Weight Range | 80g/m² – 1500g/m² |

| Width | 1 meter to 8 meters (customizable) |

| Length | Customized based on project requirements |

| Color | White, Black, Grey (or customized) |

| Standards | GB/T17638-2017 — Geosynthetics — Staple Fiber Needle-Punched Nonwoven Geotextile JT/T520-2004 — Geosynthetics for Highway Engineering — Staple Fiber Nonwoven Geotextile |

| Key Features: | High chemical and UV resistance Excellent puncture and tear strength Superior water permeability and filtration Flexible and easy to install Long-lasting and cost-effective performance |

Application

Impermeable liner protective layer: Its primary function is to provide cushioning and protection. When selecting a puncture resistance criterion (related to weight), a weight of 250-300 g/m² or higher is commonly used to provide adequate protection.

Drainage and Filtration: Its main advantages lie in its three-dimensional structure and good permeability. When selecting a system, its permeability coefficient should be considered to ensure smooth drainage.

Slope reinforcement: Its high tensile strength is the primary advantage. When selecting a strain, special attention should be paid to its longitudinal and transverse breaking strength (kN/m) to meet reinforcement requirements.

Packaging & Delivery

Delivery Terms & Process

This section clarifies responsibilities and timelines.

Lead Time: Clearly state the standard production time after order confirmation/deposit payment (e.g., 7-15 working days). This varies with order volume and product specification.

Incoterms: Define the delivery responsibility. Common terms include:

EXW (Ex Works): Buyer handles all transportation and risk from the supplier's factory.

FOB (Free On Board): Supplier delivers and loads goods onto the ship at the origin port. Buyer handles main shipping and destination costs.

CIF (Cost, Insurance & Freight): Supplier pays for main shipping and insurance to the destination port. Buyer handles import clearance and onward transportation.

About Us

Shandong Yibo Yangguang Engineering Materials Co., Ltd. positions itself as a comprehensive solutions provider, offering everything from high-quality materials to technical support and installation guidance for civil and environmental engineering projects worldwide.

Our Company Services

Our strength is our team: deeply knowledgeable engineers who bridge civil and geotechnical disciplines.

We deliver solid planning and trustworthy solutions that keep your project on track. The result is fewer interruptions and a seamless progression from design to reality.