Advanced HDPE Geomembrane

High Chemical Resistance: Excellent durability in harsh environments.

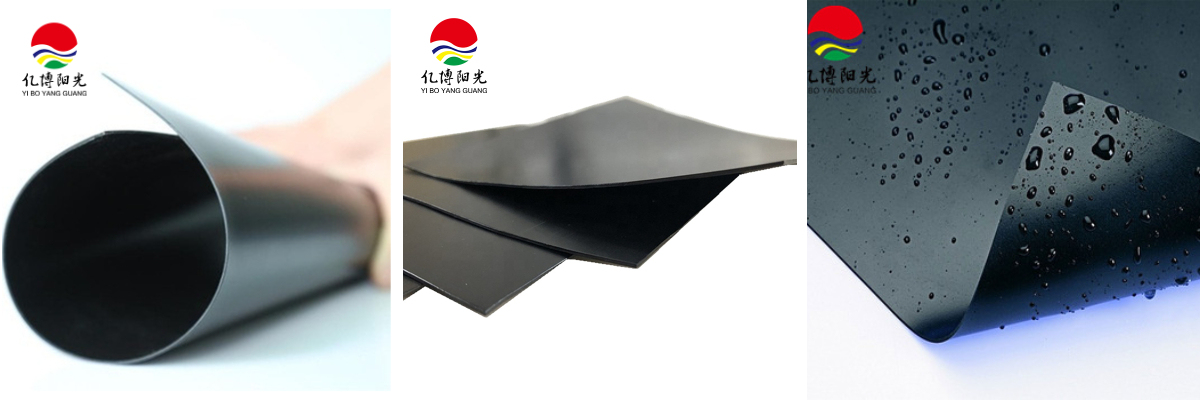

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

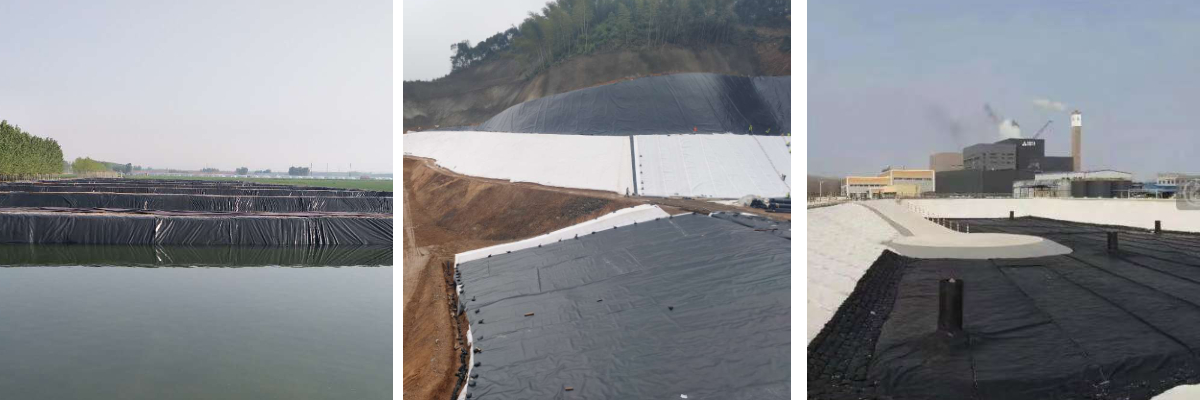

Advanced HDPE Geomembrane is a high-end and dependable option in the world of geosynthetic engineering, well-known for its remarkable performance in environmental protection, chemical resistance, and durability. Made with cutting-edge production techniques and high-density polyethylene resin, this geomembrane product not only satisfies international quality standards but also surpasses the specifications of numerous challenging engineering projects. Advanced HDPE Geomembrane offers a strong barrier that successfully stops the leakage of liquids and gases, protecting the environment and guaranteeing the long-term stability of engineering structures whether it is utilized in landfill liners, water conservation facilities, mining tailings ponds, or agricultural irrigation systems.

Product Specifcations

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

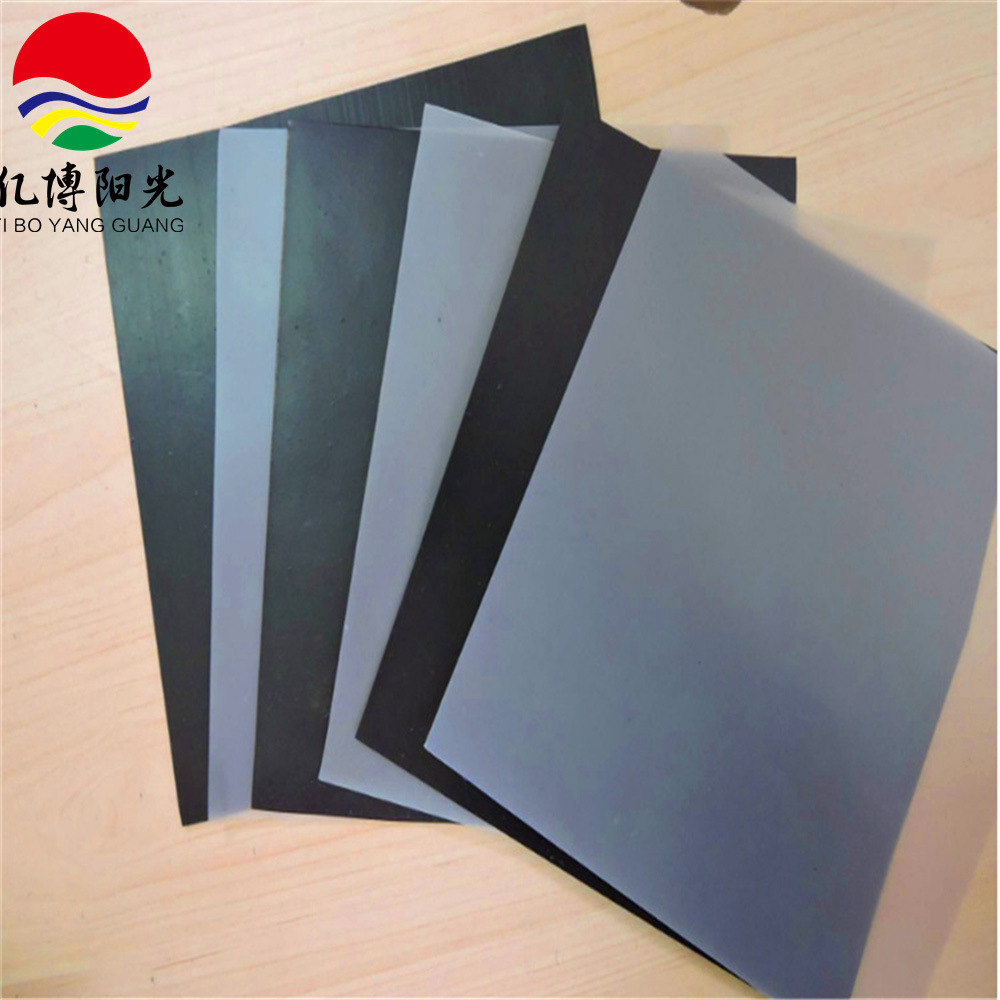

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

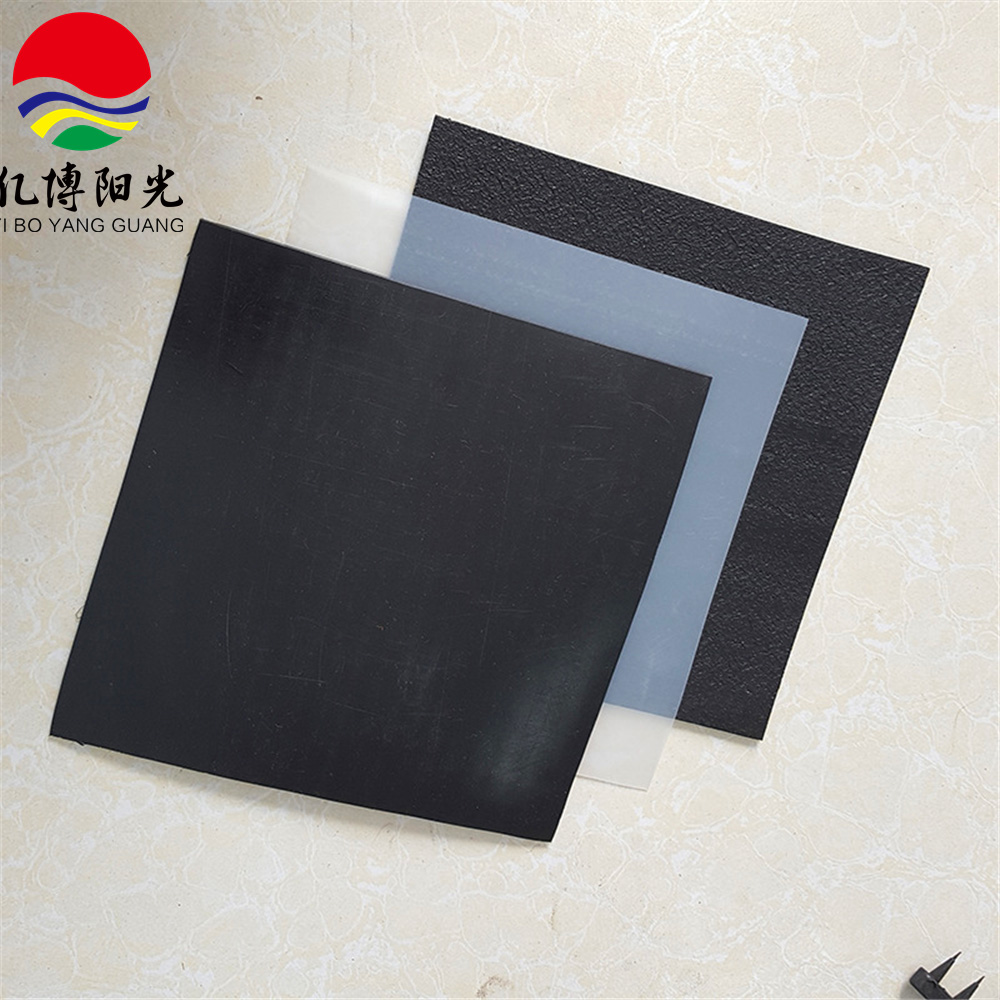

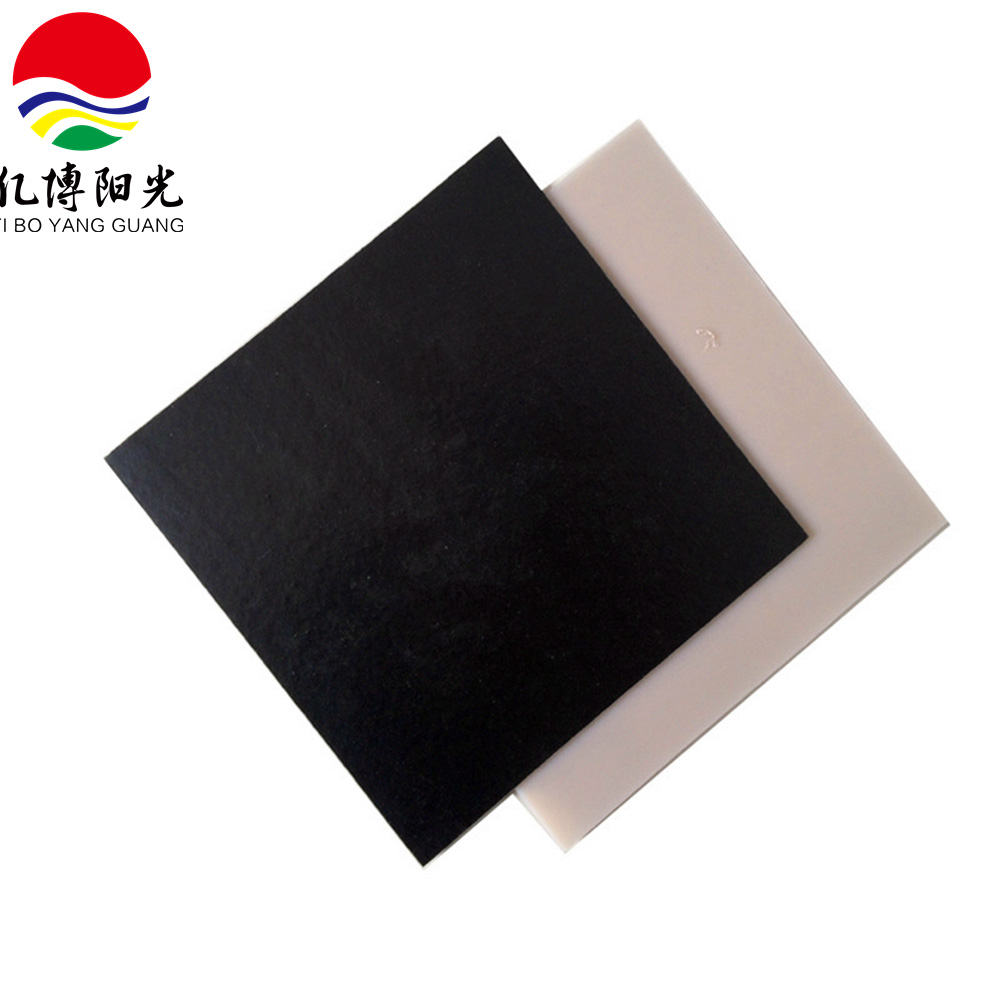

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Applications of Advanced HDPE Geomembrane

1. Waste Management: Advanced HDPE Geomembrane is used as the primary and secondary liner systems in landfill sites to prevent leachate from seeping into the groundwater. It also acts as a cover membrane to control odors, reduce methane emissions, and prevent rainwater infiltration, improving the overall management efficiency of landfills.

2. Water Conservancy and Hydraulic Engineering: It is widely used as a liner in reservoirs, ponds, canals, and dams to reduce water seepage loss. For instance, in agricultural irrigation canals, the geomembrane lining can significantly improve water utilization efficiency by minimizing seepage, ensuring that more water reaches the farmland. In reservoirs, it helps to maintain water levels and prevent soil erosion on the reservoir banks.

3. Mining Industry: Advanced HDPE Geomembrane serves as a barrier to keep leachate and tailings contained in heap leach pads and mining tailings ponds. It protects the ecological environment of the mining area and complies with environmental protection standards by preventing heavy metals and other harmful elements from contaminating soil and groundwater.

4. Industrial Facilities: This geomembrane is used for secondary containment of storage tanks and treatment ponds in chemical facilities, petroleum storage terminals, and wastewater treatment plants. It reduces the possibility of environmental contamination and stops the spread of dangerous materials by adding an extra layer of defense against unintentional spills and leaks.

5. Aquaculture: To stop water seepage and preserve water quality, Advanced HDPE Geomembrane is utilized as a liner in shrimp farms and fish ponds. Additionally, it prevents bugs and weeds from growing on the pond bottom, which lessens the need for chemical treatments and improves the habitat for aquatic life.

Packaging & Delivery

Nested packaging for space efficiency. Priority customs clearance service.

Key Advantages:

10-year UV resistance guarantee

Third-party certified material traceability

Anti-static packaging options

About Us

Strategic partner for national infrastructure projects.

Quality Assurance and Standards

Our Advanced HDPE Geomembrane is produced strictly in compliance with international standards including ISO 9001 quality management system and ASTM GM13. To make sure they meet or surpass the required quality standards, every batch of products is put through a thorough testing process that includes tensile strength, rip strength, puncture resistance, permeability, and thickness measurement. We give our customers complete assurance regarding the functionality and dependability of our products by providing thorough quality certificates and test reports for every shipment.

Our Services

Digital twin installation simulations

Emergency replacement protocols

ESG compliance reporting