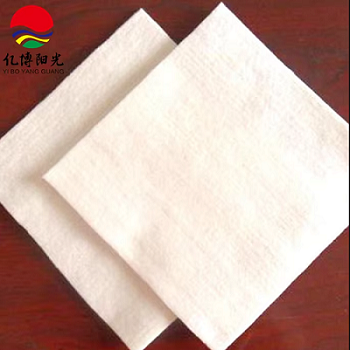

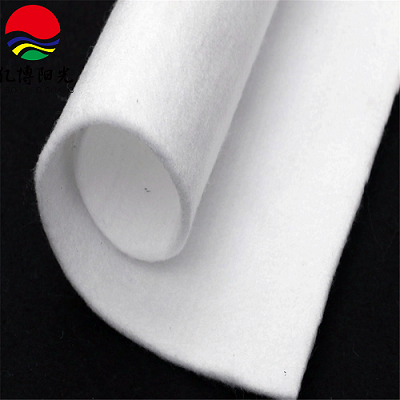

PET Polyester Needle Geotextile

High Chemical Resistance: Durable against acids, alkalis, and other chemicals.

UV & Weather Resistant: Reliable performance in outdoor conditions.

Superior Puncture Resistance: Withstands heavy loads and sharp objects.

Excellent Filtration & Drainage: Prevents soil migration while allowing water flow.

Flexible Installation: Easy to cut, weld, and lay on-site.

Cost-Effective: Long service life with minimal maintenance.

Product Introduction

(1) Brief introduction.

Non-woven polyester geotextile is made of polyester staple fiber on cross-laying equipment and needling equipment.

It has the advantages of acid and alkali resistance, erosion resistance, aging resistance, high strength, dimensional stability and good filtration.

(2) Characteristics

1. High strength: due to the use of plastic fibers, it can maintain sufficient strength and elongation even in a wet state.

2. Corrosion resistance: it can resist corrosion for a long time in soil and water with different ph values.

3. Good permeability: there are gaps between the fibers, so it has good porosity.

4. Good antimicrobial properties: not damaged by microorganisms and insects.

5. Convenient construction: Because the material is light and soft, it is easy to transport, lay and construct.

Product Specifications

| Material | 100% Polyester (PET) Staple Fiber |

| Fabric Type | Needle-Punched Nonwoven Geotextile |

| Weight Range | 80g/m² – 1500g/m² |

| Width | 1 meter to 8 meters (customizable) |

| Length | Customized based on project requirements |

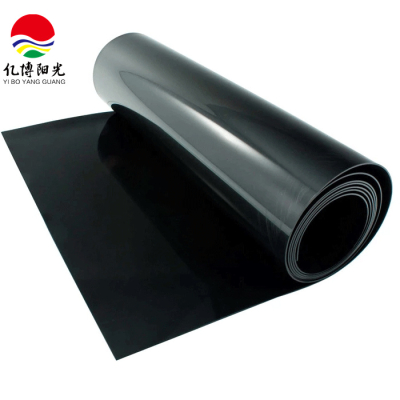

| Color | White, Black, Grey (or customized) |

| Standards | GB/T17638-2017 — Geosynthetics — Staple Fiber Needle-Punched Nonwoven Geotextile JT/T520-2004 — Geosynthetics for Highway Engineering — Staple Fiber Nonwoven Geotextile |

| Key Features: | High chemical and UV resistance Excellent puncture and tear strength Superior water permeability and filtration Flexible and easy to install Long-lasting and cost-effective performance |

Application

Main functions Isolation, filtration, drainage, reinforcement, protection and liquid barrier

1) Filtration Filtering layer for dikes, rivers and canals, seashores, concrete berms, and retaining walls. While preventing the passage of clay particles, it allows water and gas to pass freely.

2) Separation Separates railroad spoils from roadbeds, roadbeds from softbeds, surfaces and ground surfaces of airports and parking lots, and different dam materials. Isolates soil and gravel of two different grain sizes from the ground or other structures.

3) Increase muscle Roads, railroads, earth and rock dams, breakwaters, airports, retaining wall backfill, berms, etc., which can disperse soil stress, prevent lateral movement of the soil, and improve the stability of the soil.

4)Protection Prevent scouring of embankment, protect embankment and embankment bottom from water and soil scouring.

Packaging & Delivery

Delivery time: 7-10 working days after receipt of deposit

Packing: Reel with mandrel, double-layer UV-proof woven bag

About Us

Shandong Yibo Sunshine Engineering Materials Co., Ltd. is located in Jinan City, Shandong Province. It is a high-tech enterprise specializing in the research and development, production, sales and construction of geomaterials and related products such as high-density polyethylene (HDPE) geomembrane, textured geomembrane, filament (staple fiber) geotextile fabrics, composite geomembrane, EVA waterproofing board, polymer self-adhesive waterproofing board, bentonite waterproofing blanket, composite drainage net and so on. They are widely used in railroads and highways, bridges and tunnels, reservoirs, channels and water conservancy, wetland parks, landfills, ash dams and slag disposal sites, mine seepage control, salt industry, chemical industry, agriculture, animal husbandry and fishery industries.

Our Company Services

Quality Assurance System

1. Third-party certification

Cooperate with CNAS-accredited laboratories for product verification testing, the frequency can be customized according to customer requirements.

2. Whole Process Control

Implement ISO 9001 certified quality management in R&D, production and inspection workflow to ensure traceable compliance from raw materials to finished products.

3. Quality Commitment

- 24/7 technical support

- Extended warranty for production defects (excluding: force majeure events or misuse)

- On-site remediation of verified quality incidents within 48 hours

After-sales service agreement

1. Technical support

- Provision of BIM models, installation simulations and product lifecycle documentation

- Dedicated account manager for corporate customers

2. Professional Services

- On-site supervision by certified installation supervisors

- Customized training programs, including

Product specifications

Best maintenance practices

Troubleshooting methods

3. Logistics Protection

- Comprehensive all-risk cargo insurance

- Damage claims resolved within 72 hours (visual evidence required)

4. Project handover

- Joint commissioning with customer's quality assurance team