Long Lasting LLDPE Geomembrane

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

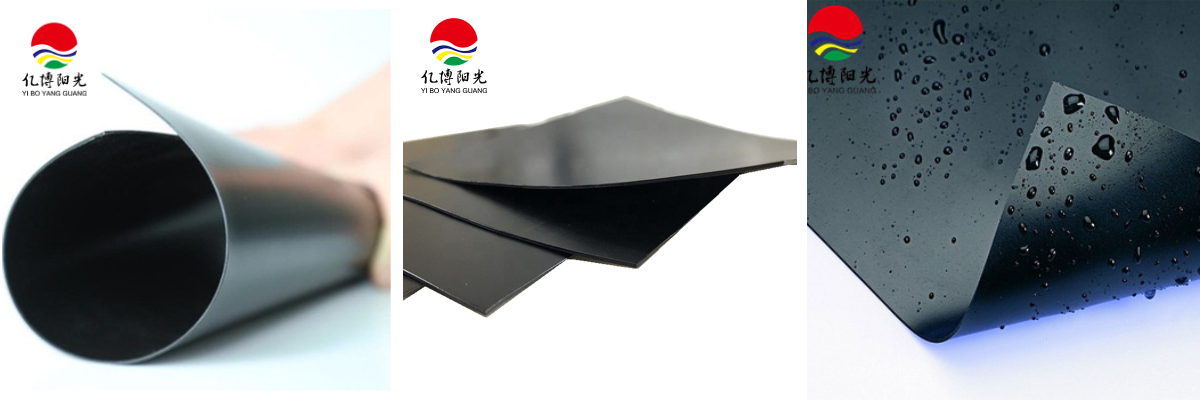

LLDPE geomembrane is widely regarded as the optimal solution for seepage prevention due to its outstanding technical performance. Its advanced material properties make it particularly effective in applications requiring adaptability to substantial substrate deformation and complex stress dynamics, guaranteeing dependable long-term containment in harsh environmental conditions.

Product Specifications

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

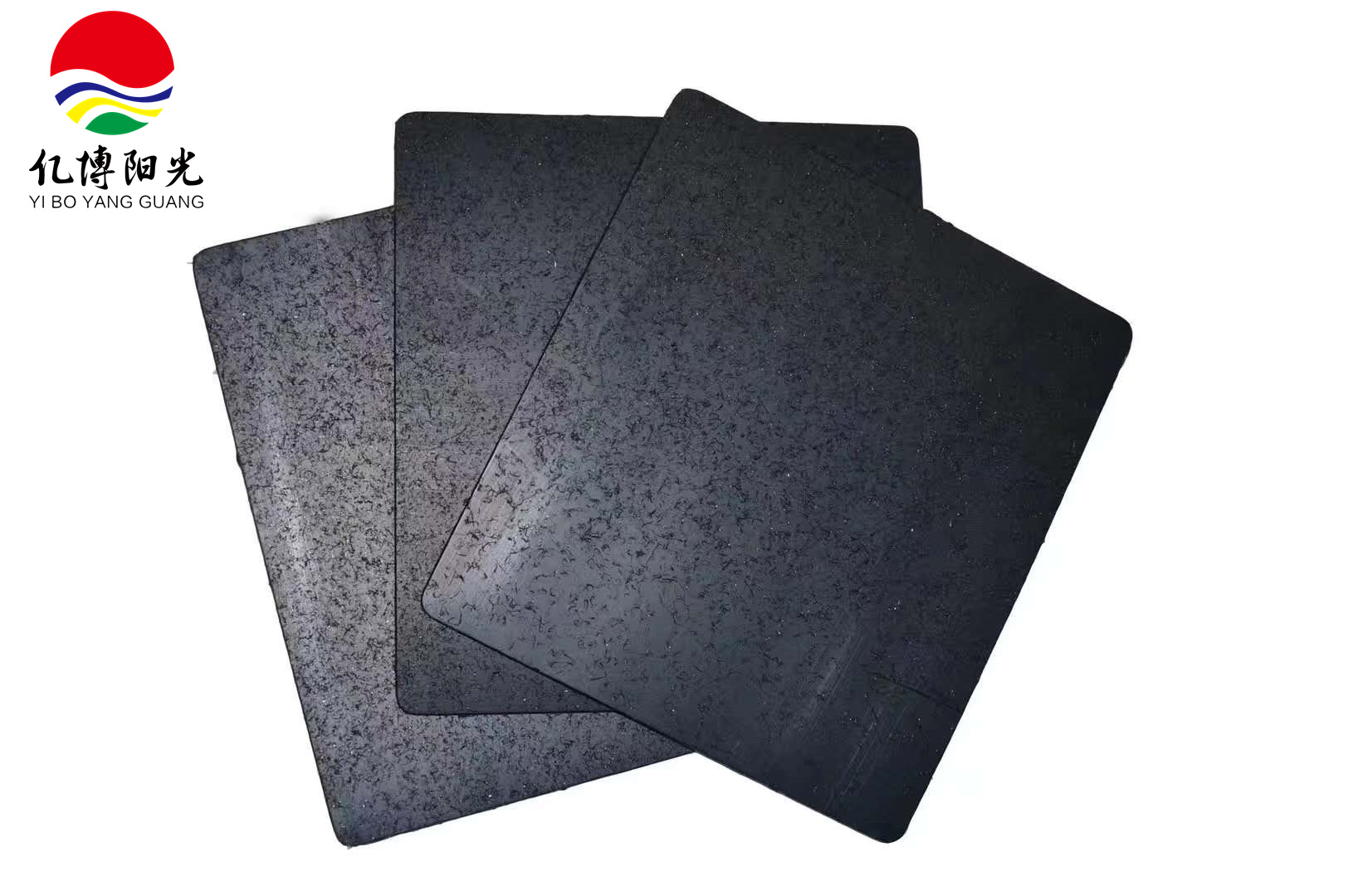

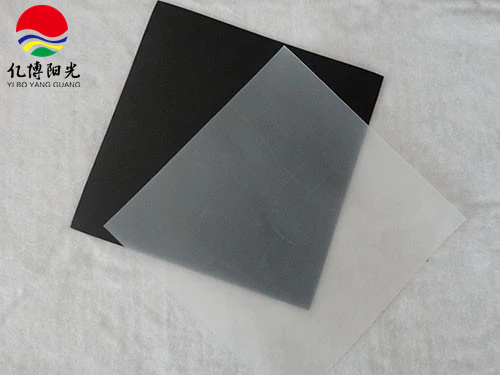

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Application Scenarios

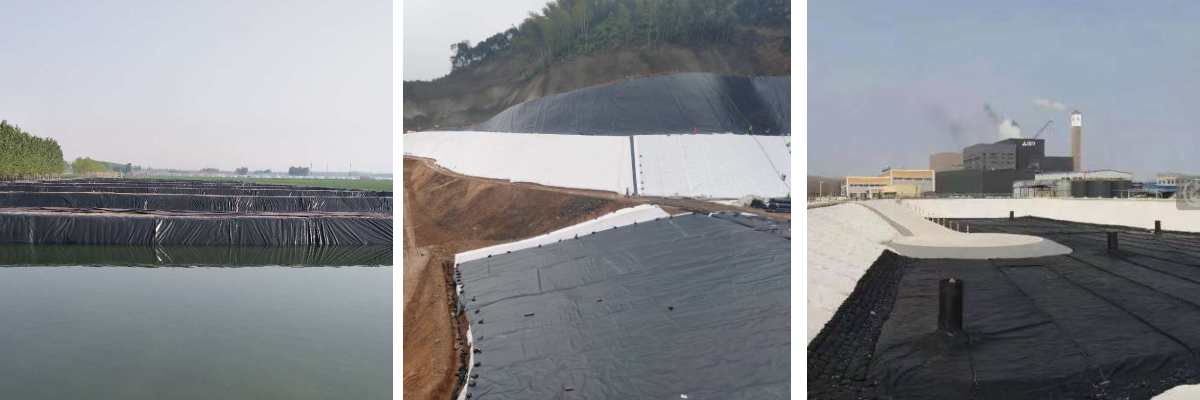

Full-Scale Landfill Encapsulation

Primary/secondary liners & capping systems with multi-layer composite barriers (ASTM D7703 compliant).

Dynamic Waste Management Facilities

Bioreactor landfills with ground movement compensation (≥500% elongation).

Expanding landfill cells requiring strain-resistant membrane joints.

Engineered Water Retention Systems

Seepage-controlled man-made lakes & irrigation reservoirs (permeability ≤1×10⁻¹¹ cm/s).

Hazardous Chemical Containment

Acid-resistant liners for chemical processing zones & double-lined tailings dams (ISO 11348 certified).

Packaging & Delivery

Inventory Assurance

Pre-positioned inventory of 30,000+ m² geosynthetics for instant deployment.

Real-time stock monitoring via IoT-enabled warehouse management systems.

Rapid Response Manufacturing

24/7 continuous production capability for custom-engineered geosynthetic specifications.

Digital twin technology ensures design accuracy and rapid prototyping.

Expedited Dispatch Protocol

Priority handling for urgent orders with 4-hour order fulfillment (priority code required).

Multi-modal logistics hubs for global reach within 24 hours.

About Us

We are specialized in the development, manufacturing, sales, and construction of geomaterials and their supporting products, specializing in the production of: HDPE geomembrane, Rough geomembrane, Composite geomembrane, EVA waterproof board, Polymer self-adhesive waterproof board, Bentonite waterproof blanket, Filament (short silk) geotextile, Composite drainage net and other geomaterials products.

Our Company Services

As a full-service geosynthetic solutions provider, we deliver end-to-end services from research and development to on-site installation. Our core manufacturing capabilities encompass:

Barrier Systems:

HDPE geomembranes (smooth/textured), composite geomembranes, and textured geomembranes for high-performance containment.Waterproofing Solutions:

EVA waterproof panels and self-adhesive polymer membranes for critical moisture control.Specialty Products:

Sodium bentonite geosynthetic clay liners (GCLs) and bentonite waterproof blankets for environmental protection.Drainage & Filtration Systems:

Woven/nonwoven geotextiles (monofilament/polyester staple fibers) and composite drainage nets with integrated filtration layers.

Technical Specification Style

As a vertically integrated geosynthetics specialist, we design and manufacture precision-engineered solutions:

✓ Impermeable Barriers

Smooth/textured HDPE geomembranes: 0.2–3.0 mm thickness

Multi-layer composite geomembranes (HDPE/LLDPE/EVA blends)

✓ Waterproofing Membranes

EVA copolymer sheets (thickness customizable)

Self-adhesive polymer membranes (PSA technology)

Sodium bentonite GCLs (dry density: ≥2.0 g/cm³)

PET/PP geotextiles: 200–800 g/m² (high tensile strength)

3D drainage nets with geotextile filters (permeability ≤5×10⁻³ m/s)