HDPE Geomembrane Liner Cost

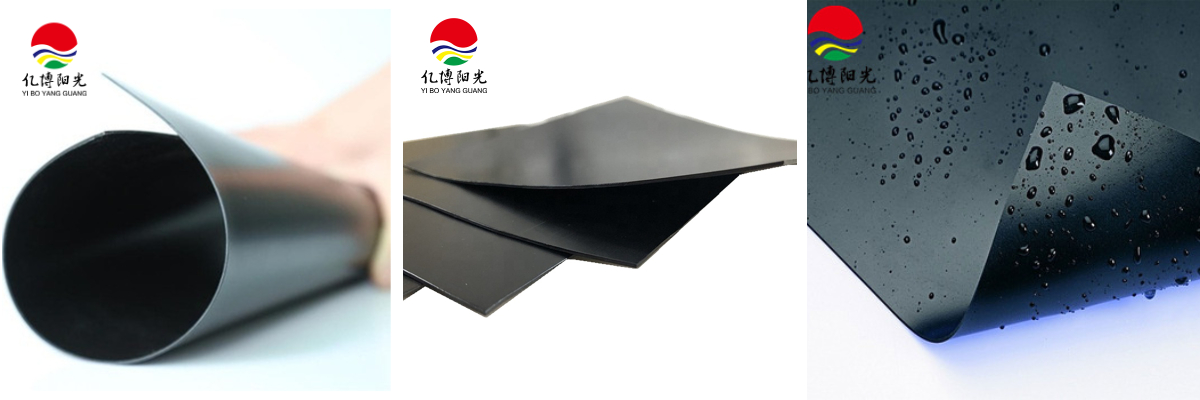

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

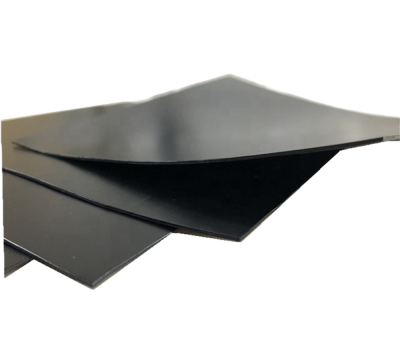

Product Introduction

Engineered for the most demanding applications, our HDPE geomembranes meet GM13 compliance while offering superior long-term performance.

With 99% UV blockage for exceptional durability and reliable flexibility down to -40°C, they provide enduring stability in extreme environments.

Product Specifications

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.1mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Application Scenarios

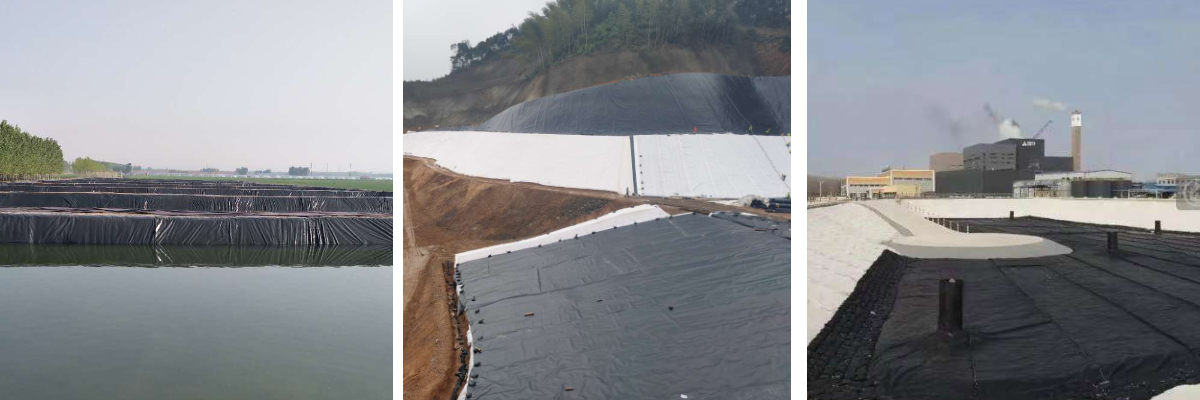

HDPE liners for food processing wastewater: guarantee environmental compliance, prevent groundwater contamination, and contain organic loads and fats.

Chemical resistance and zero-leakage integrity make pharmaceutical containment liners essential for risk reduction and regulatory compliance.

Urban sewage plant liners are essential for protecting the environment and public health due to their high volume capacity and long-term durability.

Pipeline project liners are essential for large-scale linear infrastructure because they meet international environmental standards and provide secondary spill containment.

High salinity and chemical resistance desalination plant liners line evaporation ponds and concentrate areas, guarantee process effectiveness, and protect the environment.

Packaging & Delivery

Packaging appropriate for delicate environments in a cleanroom. Choices for logistics with temperature control.

Principal Advantages

NSF 61 certification is available.

Customized antimicrobial supplements

Zero VOC emissions are guaranteed.

About Us

Technical partner for national infrastructure projects, supplying:

Conductive geomembranes

Bentonite-polymer composites

High-strength geogrids

Our Services

Digital thickness mapping

On-demand rheology adjustments

Carbon footprint reporting