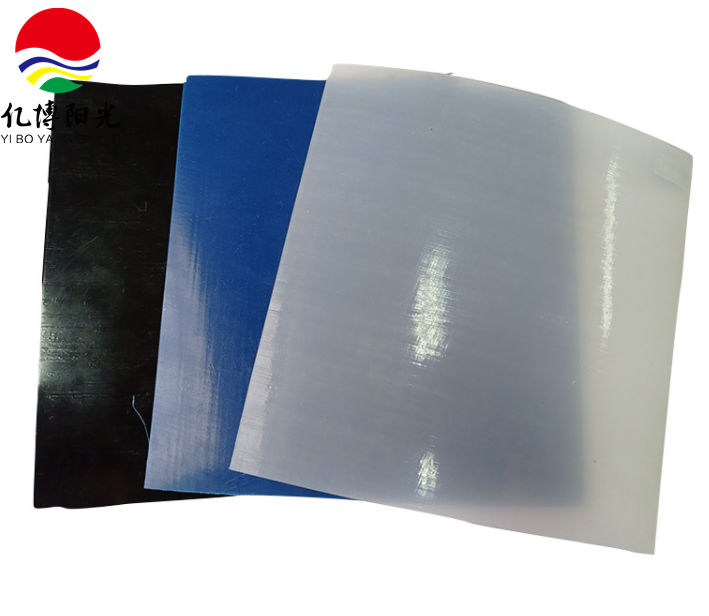

Smooth Geomembrane

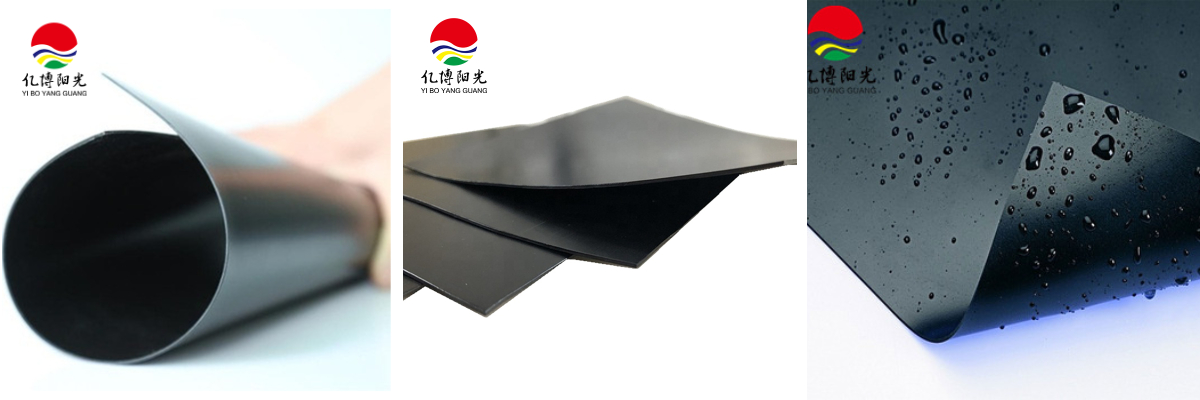

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

Engineered with molecular stabilization technology, our HDPE geomembranes utilize high-purity polyethylene granules processed through multilayer co-extrusion. This innovative method achieves industry-leading dimensional stability (±0.5% thickness variance) while maintaining 98% UV reflectivity. The smooth-surface variant demonstrates exceptional stress crack resistance (>10,000 hours per ASTM D5397), making it indispensable for critical containment systems.

Product Specifcations

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

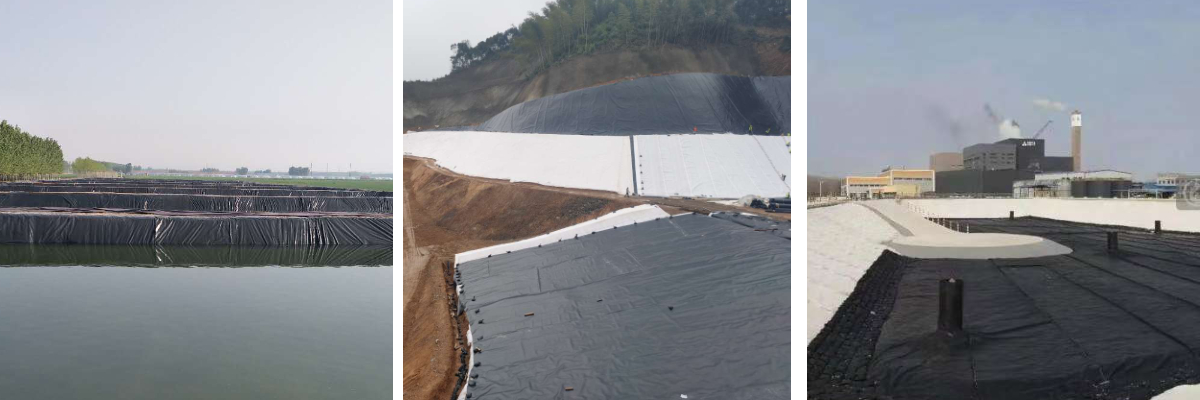

Application Scenarios

Waste Management: Base lining for toxic sludge ponds and incineration ash storage

Hydropower Infrastructure: Penstock tunnel waterproofing and surge chamber protection

Green Architecture: Rooftop garden moisture barriers and vertical green wall systems

Oil & Gas: Secondary containment for fuel storage farms and pipeline corridors

Cold Chain Logistics: Temperature-controlled warehouse vapor barriers

Disaster Prevention: Flood control sacs and emergency spillway liners

Prefab Structures: Modular biogas digesters and mobile water treatment plants

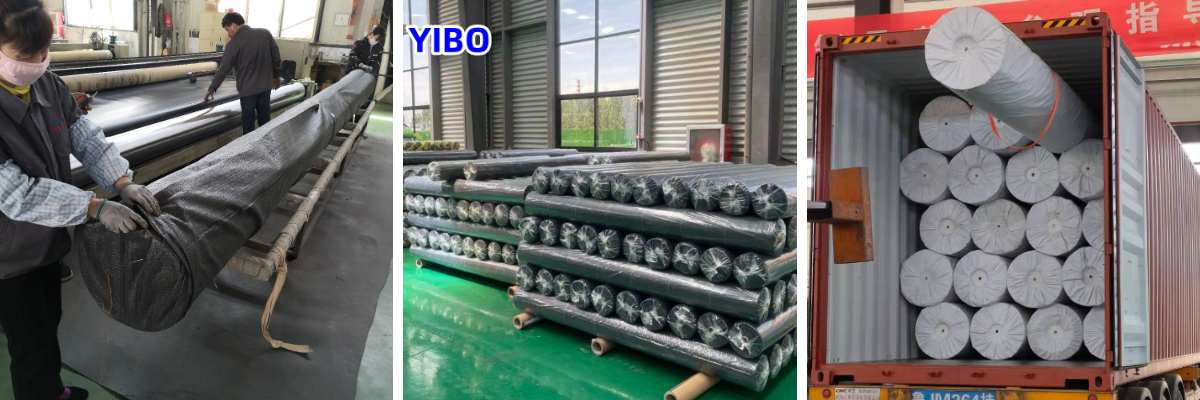

Packaging & Delivery

Advanced palletization systems ensure damage-free global distribution. With dual-shift production capabilities, we guarantee 72-hour dispatch for standard orders.

Core Delivery Features:

Climate-Controlled Storage

Laser-Cut Edge Protection

Bilingual Documentation

Custom HS Code Labeling

Real-time vessel tracking accessible via our proprietary logistics portal.

About Us

Pioneers in polymer engineering since 2008, we deliver full-spectrum geosynthetics including:

HDPE/LDPE/LLDPE geomembranes

Conductive leak detection liners

Geocomposite drainage panels

Bentonite-polymer hybrid sheets

Our Company Services

Turnkey solutions from material specification to installation supervision.

Technical Edge:

15-Year Accelerated Aging Test Data

On-Demand Rheology Modifications

APEC Engineer-Certified Designs