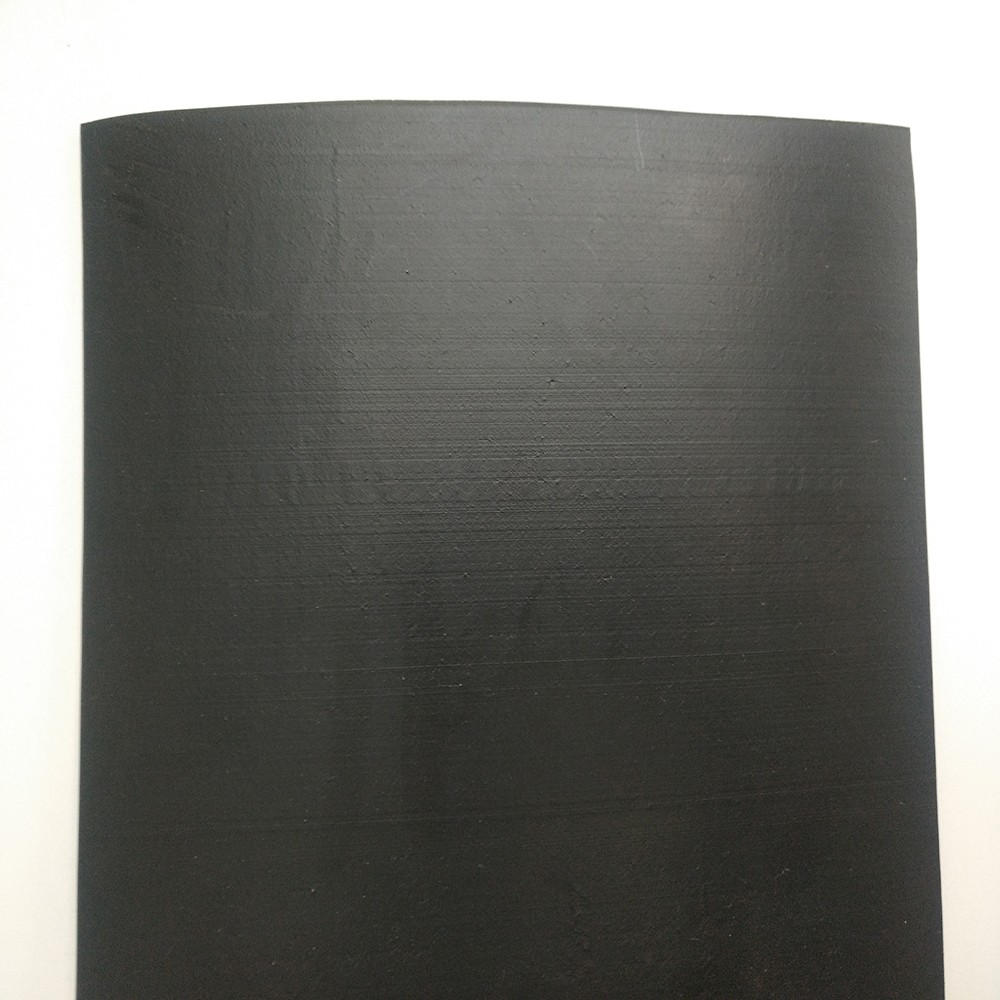

60Mil Black Large Pond Liner

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

60Mil Black Large Pond Liner is a 60-mil (approximately 1.5 mm) thick black high-density polyethylene (HDPE) pond geomembrane roll specifically designed for large-scale water body seepage control projects.

It is acid and alkali resistant, corrosion resistant, unaffected by chemicals in the soil, and has a service life of over 50 years. The addition of carbon black provides excellent UV resistance, and it is suitable for temperatures ranging from -60°C to 60°C.

The 60-mil thickness offers good mechanical strength and puncture resistance, making it suitable for complex foundation conditions. Hot-melt welding ensures high joint strength, fast construction speed, and effectively reduces project costs. Compared to traditional geomembranes, it offers higher overall benefits.

Product Specifcations

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Application Scenarios

Landscape Engineering: Large-scale water features such as artificial lakes, landscape ponds, and golf course pools.

Additional Uses: Industrial seepage avoidance projects include salt fields, tailings ponds, and tunnel waterproofing.

Packaging & Delivery

Pallet Packaging

Multi-roll products are packaged together on wooden or plastic pallets.

Stretch film is used for securing the product, ensuring safe transport.

Suitable for large orders, easy for forklift loading and unloading.

Special Packaging

Packaging methods can be customized according to customer requirements. Waterproof, moisture-proof, and UV-resistant special packaging solutions are available.

Delivery Time:

Standard Products: 3-7 working days

Special Specifications: 7-15 working days

Custom Products: Determined based on order quantity and production process; specific delivery date is subject to contract agreement.

About Us

We are experts in the development, manufacturing, and worldwide distribution of geosynthetic materials. Our goal is to provide dependable, high-performing geomembranes, geotextiles, geogrids, and related solutions to clients globally, supported by 20 years of industry experience.

Our Main Advantages:

Advanced Production Capacity: Our facility has completely automated procedures that guarantee unparalleled product consistency, along with high-precision production technology from top European manufacturers.

Unwavering Standards of Quality: We follow important international standards including GB/T, ASTM, and GRI while operating under an ISO 9001 certified quality management system. To attain the ideal release rate, every production batch is carefully verified.

Our Company Services

In-sales Service

Production Monitoring

Monitor the entire production process to ensure stable quality.

Provide production progress reports for real-time customer monitoring.

Support customer on-site inspection.

Logistics and Distribution

Provide professional logistics solutions.

Fast delivery nationwide.

Support door-to-door service.

Technical Support

Provide construction technical guidance.

Assist in resolving technical problems during construction.

24-hour technical hotline support.

After-sales Service

Quality Assurance

Product warranty period of XX years.

Provide a product quality commitment letter.

Lifetime maintenance service.