HDPE Pond Liner Roll

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

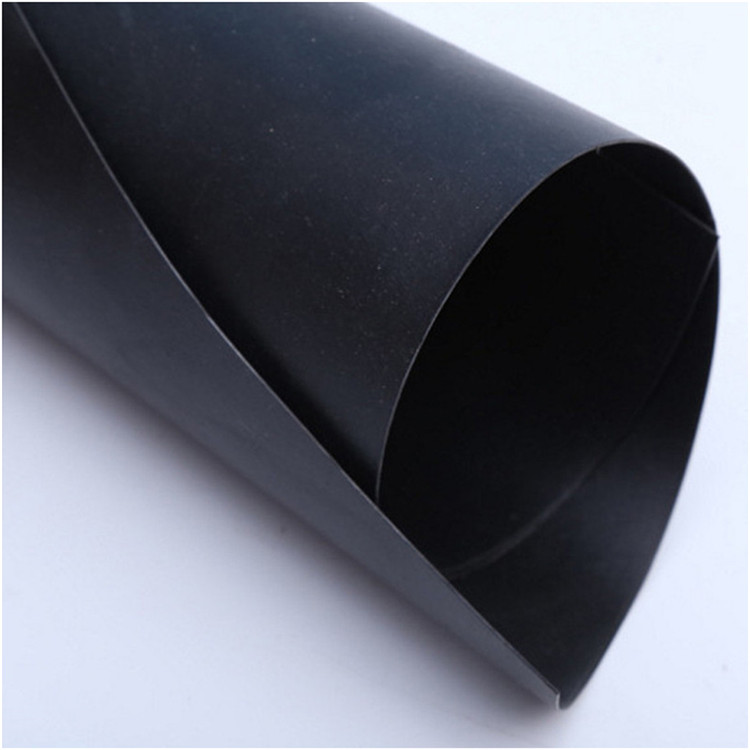

A high-density polyethylene geomembrane roll made especially for controlling pond seepage is called an HDPE Pond Liner Roll. For ease of transportation and installation, it is usually provided in roll form. This material has exceptional mechanical strength and seepage control performance because it is manufactured from high-density polyethylene (HDPE) resin using an extrusion blow molding method.

The flexible and lightweight HDPE Pond Liner Roll makes on-site installation and shipping easier. It effectively lowers project costs by using hot-melt welding for high joint strength and quick assembly. It provides greater overall benefits than conventional seepage control solutions, usually resulting in cost savings of about 42%.

Product Specifcations

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

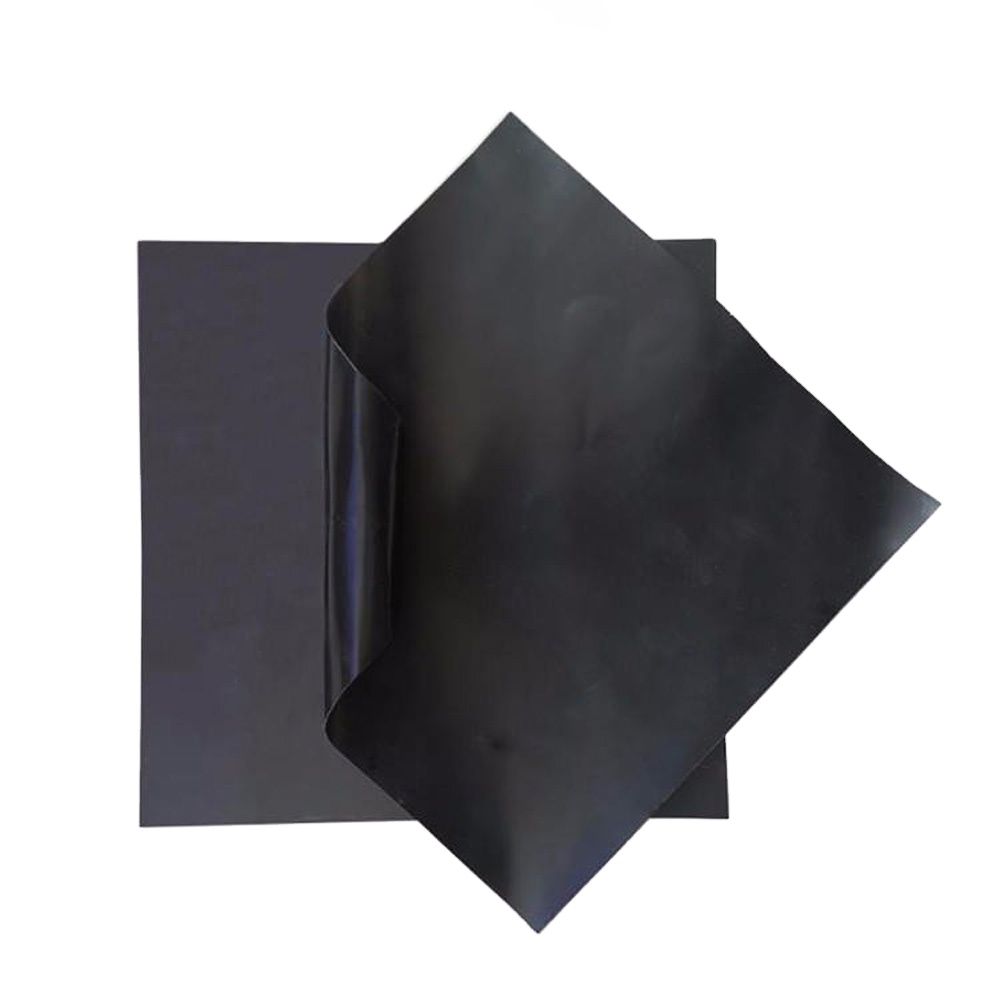

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Application Scenarios

Aquaculture: Seepage prevention for fishponds, shrimp ponds, lotus ponds, and other aquaculture water bodies to provide a good living environment for aquatic organisms.

Artificial landscapes include golf course ponds, artificial lakes, landscaping ponds, and river seepage control.

Engineering seepage avoidance for seawater aquaculture in sea cucumber and abalone farming ponds.

Packaging & Delivery

Packaging Method

Typical roll packing. For wrapping, an outer moisture-proof film is attached to high-strength woven fabric or PE film. Both ends of the roll are covered with hard plastic or wooden end caps to avoid damage during shipment. For ease of loading, unloading, and storage, each roll is packaged separately.

Ocean Freight

Container shipping, ensuring waterproofing and moisture protection; fumigation certificate provided (if required); compliant with international shipping standards.

About Us

We are a high-tech enterprise specializing in the R&D, production, and sales of geosynthetics. With 20 years of industry experience, we are committed to providing global customers with high-quality geomembranes, geotextiles, geogrids, and other related products.

Core Advantages:

Advanced Production Equipment

Imported advanced production lines from Germany and Italy

Employed fully automated control systems to ensure stable product quality

Strict Quality Control

Certified by ISO9001 Quality Management System

Products comply with domestic and international standards such as GB/T, ASTM, and GRI

Each batch of products undergoes rigorous testing to ensure a 100% pass rate.

Our Company Services

Pre-sales Service

Technical Consultation

Provide free technical consultation and solution design

Recommend suitable product specifications based on project needs

Assist clients with project budgeting and material selection

Sample Support

Provide free samples for client testing

Support customized samples to meet special needs

Fast delivery, arriving within 3 business days

Site Visit

Arrange technical personnel for on-site inspection

Provide professional technical guidance

Assist in solving on-site technical problems