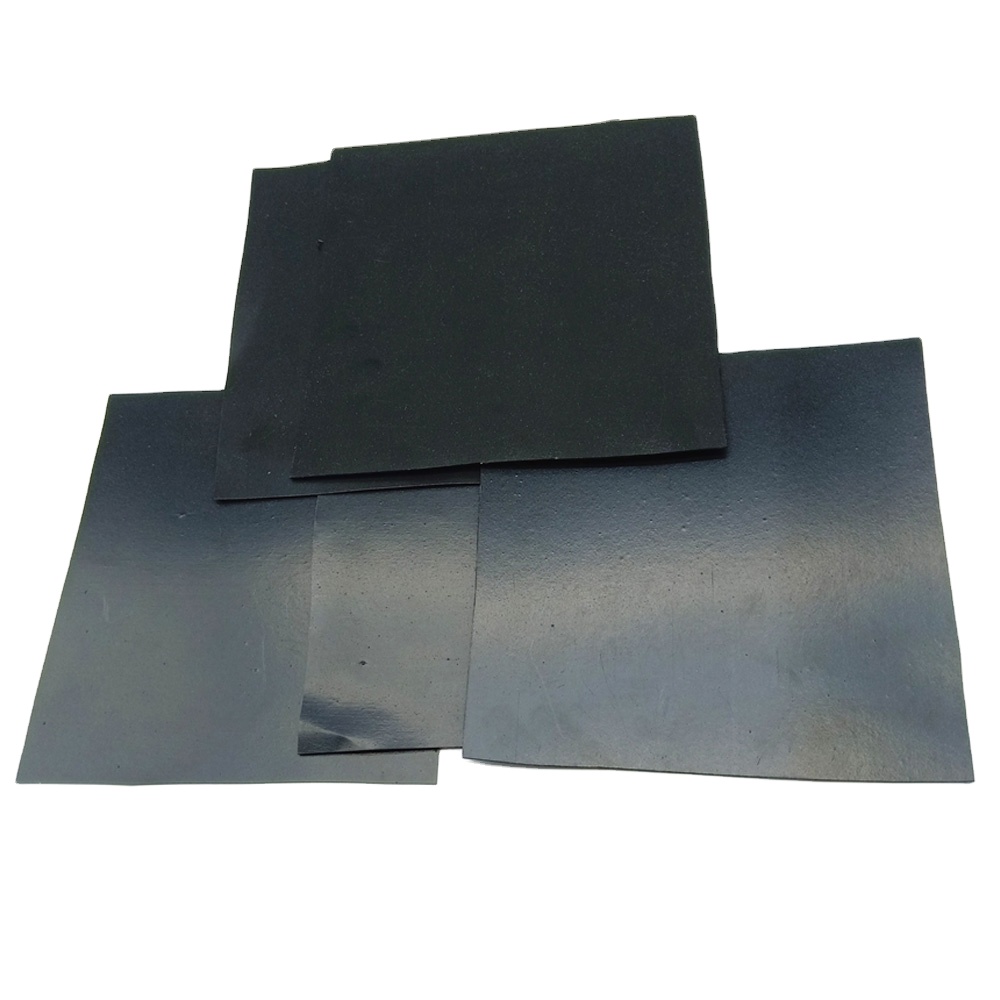

HDPE Geomembrane Sheet

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

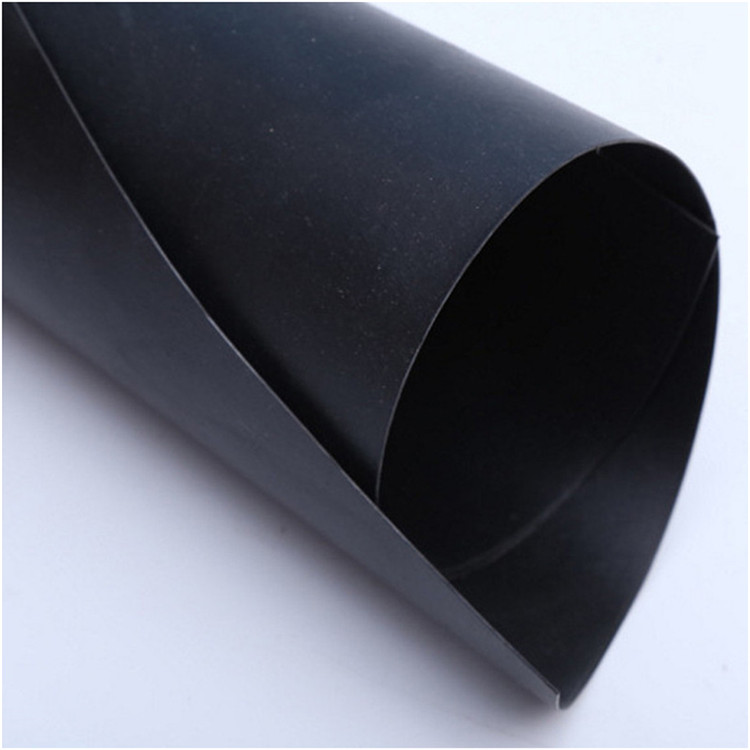

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

Because of its exceptional protective qualities, resistance to harsh chemicals, and long-lasting performance, premium HDPE geomembrane stands out as a superior and dependable solution in the field of geosynthetic engineering. This geomembrane, which is made from premium polyethylene resin uing cutting-edge technology, not only satisfies but frequently surpasses strict international standards and the exacting specifications of intricate infrastructure applications. It guarantees environmental safety and structural integrity in a variety of applications, from landfill containment and water resource management to mining tailings storage and agricultural water systems, by forming an impermeable seal against both liquid and gas migration.

Product Specifcations

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Application Scenarios

Canals for agricultural irrigation

Preventing seepage in water storage tanks

Improvement of saline-alkali land

Water-efficient irrigation system

Packaging & Delivery

Space-Optimized Nested Design | Expedited Customs Clearance

Core Benefits:

10-Year Guaranteed UV Stability

Full Material Traceability (Third-Party Certified)

Optional Anti-Static Packaging Solutions

About Us

We have been at the forefront of polymer engineering since 2008, providing a wide range of geosynthetic solutions, including:

HDPE, LDPE, and LLDPE grades of polyethylene geomembranes

Electrically conductive liners to track leaks

Drainage panels made of composite

Polymer barrier sheets reinforced with bentonite

Our Company Services

Delivering the project from start to finish, from choosing the materials to supervising the on-site installation.

Technical Benefits:

15-Year Accelerated Testing Validates Aging Performance

APEC-Accredited Engineers Certify Designs

Customized Rheological Properties Available Upon Request