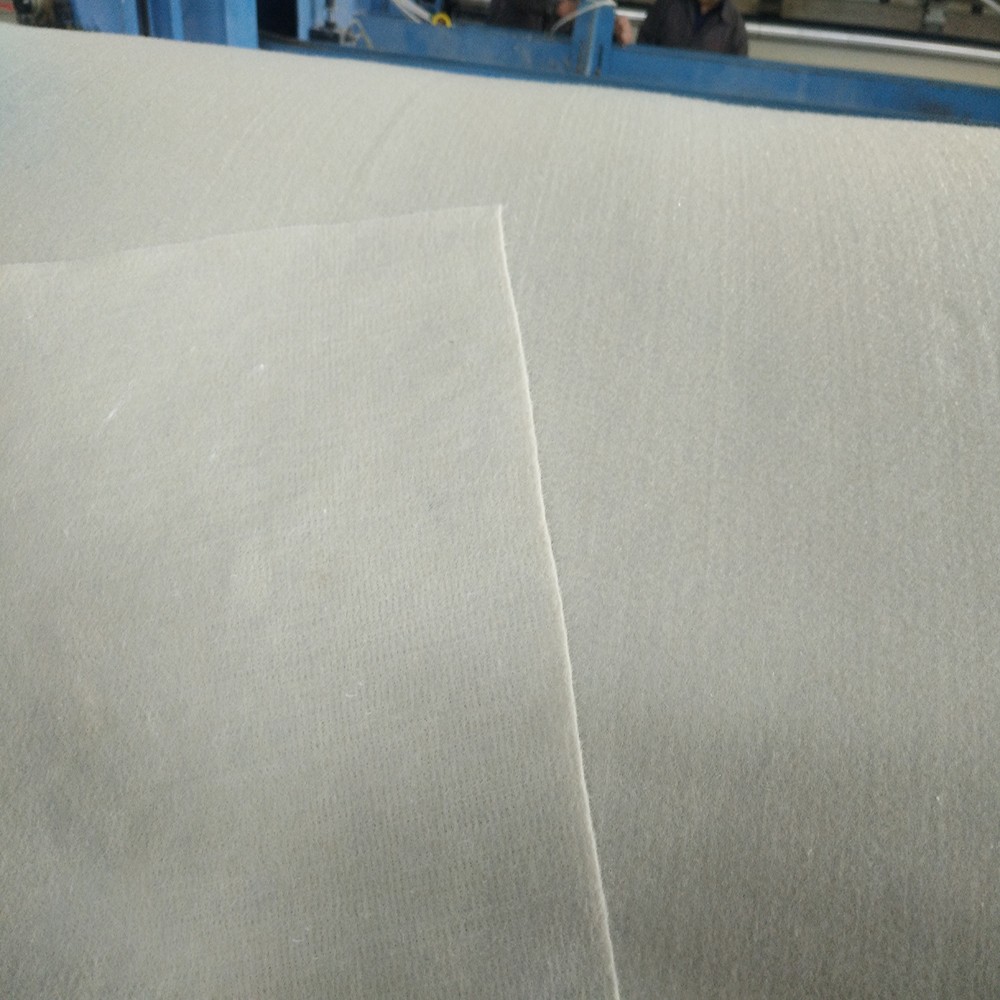

White Polyester Geotextile Fabric for Ponds

High Chemical Resistance: Durable against acids, alkalis, and other chemicals.

UV & Weather Resistant: Reliable performance in outdoor conditions.

Superior Puncture Resistance: Withstands heavy loads and sharp objects.

Excellent Filtration & Drainage: Prevents soil migration while allowing water flow.

Flexible Installation: Easy to cut, weld, and lay on-site.

Cost-Effective: Long service life with minimal maintenance.

Product Introduction

Polyester geotextile is a high-performance engineering material that solves many challenging problems in traditional civil engineering, such as unstable foundations, soil erosion, and poor drainage, through its unique physical properties. Its strength, durability, and creep resistance make it the material of choice for many demanding engineering projects, providing a reliable, economical, and efficient solution for modern infrastructure construction.

Product Specifications

| Material | 100% Polyester (PET) Staple Fiber |

| Fabric Type | Needle-Punched Nonwoven Geotextile |

| Weight Range | 80g/m² – 1500g/m² |

| Width | 1 meter to 8 meters (customizable) |

| Length | Customized based on project requirements |

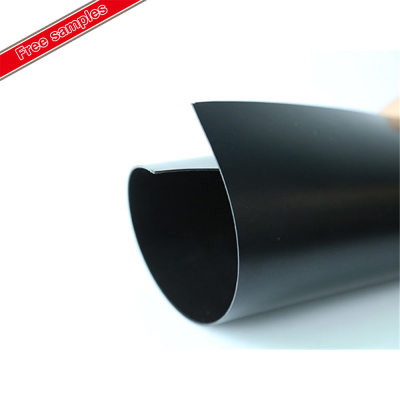

| Color | White, Black, Grey (or customized) |

| Standards | GB/T17638-2017 — Geosynthetics — Staple Fiber Needle-Punched Nonwoven Geotextile JT/T520-2004 — Geosynthetics for Highway Engineering — Staple Fiber Nonwoven Geotextile |

| Key Features: | High chemical and UV resistance Excellent puncture and tear strength Superior water permeability and filtration Flexible and easy to install Long-lasting and cost-effective performance |

Application

Dike and riverbank protection: Used for filter layers and erosion protection.

Landfill sites: Used for basement protection, leachate collection systems, and covering systems.

Building engineering: Used for basement waterproofing, roof garden drainage, etc.

Agriculture: Used for seepage prevention and protection of reservoirs and irrigation canals.

Packaging & Delivery

With our careful packing standards and streamlined global supply network, you can rely on a reliable delivery process. We make sure that every cargo is ready for travel and that products that are ready to send are dispatched on time. Additionally, we offer the flexibility of bespoke labels and, upon request, provide granular visibility into the status of your package with our round-the-clock tracking.

About Us

A complete high-tech company, Shandong Yibo Yangguang Engineering Materials Co., Ltd. combines product development, manufacturing, installation, and post-purchase support.

Geotextiles, composite geomembranes, geogrids, HDPE geomembranes, bentonite waterproof blankets, anti-aging geotechnical woven bags, dust-proof nets, shade nets, and woven bags are among the geotechnical materials that the company primarily produces.

Several sophisticated manufacturing lines, such as 6.6-meter nonwoven fabric equipment, 6.6-meter composite membrane lines, film-coating machines, blow molding machines, bentonite waterproof blanket machines, warp knitting machines, and wire drawing machines, are run by Yibo Yangguang.

Road and railroad construction, bridges, tunnels, canal water conservation projects, land reclamation, landfills, mining regions, the chemical and salt industries, agriculture, and fisheries are just a few of the industries that make extensive use of our goods.

Our materials have endured in a variety of engineering tasks.

Our Company Services

Smooth surface geomembranes, textured (rough) geomembranes, and column point geomembranes are just a few of the geomembrane products that we specialize in producing and customizing. For online corporate tours and to examine sample items, customers are welcome to get in touch with us.

Why Pick Us:

We offer full-scenario technology adaption services for everything from sponge city projects to ecological slope protection, from highway anti-filtration to landfill seepage prevention. Our engineering team may reduce the overall cost by 10% to 30% by tailoring the specs, grammage, and functional composite solutions for you based on the geological conditions, loading requirements, and other factors of the project.

Complete Service Assistance

Online Technical Assistance

Installation Services on-site

Construction Teams' On-Site Training

Product Inspection on-site

Free Supply of Spare Parts

Guarantee of Return and Replacement