Geomembrane Liner

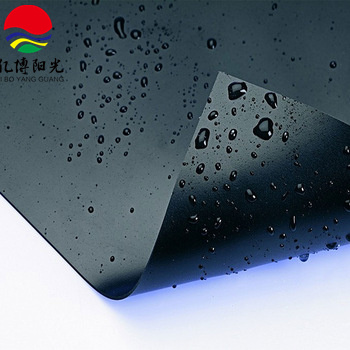

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

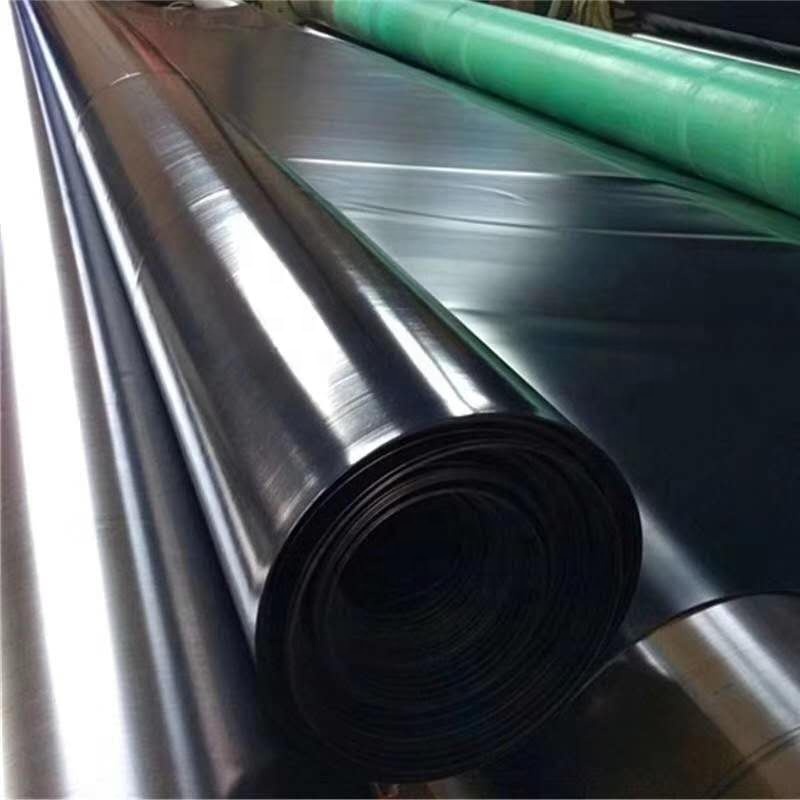

Product Introduction

Engineered to meet GM13 standards, our high-performance HDPE geomembrane liner (2.0–2.5mm thickness) delivers unmatched durability for demanding industrial environments. Manufactured using high-purity resin and advanced multilayer co-extrusion technology, it ensures superior consistency with a tight ±2% thickness tolerance.

Certified for extreme chemical resistance (pH 1–14) and long-term UV stability (15+ years), this geomembrane liner provides reliable containment and protection in harsh conditions. Ideal for landfills, mining, and wastewater treatment—where strength and longevity are critical.

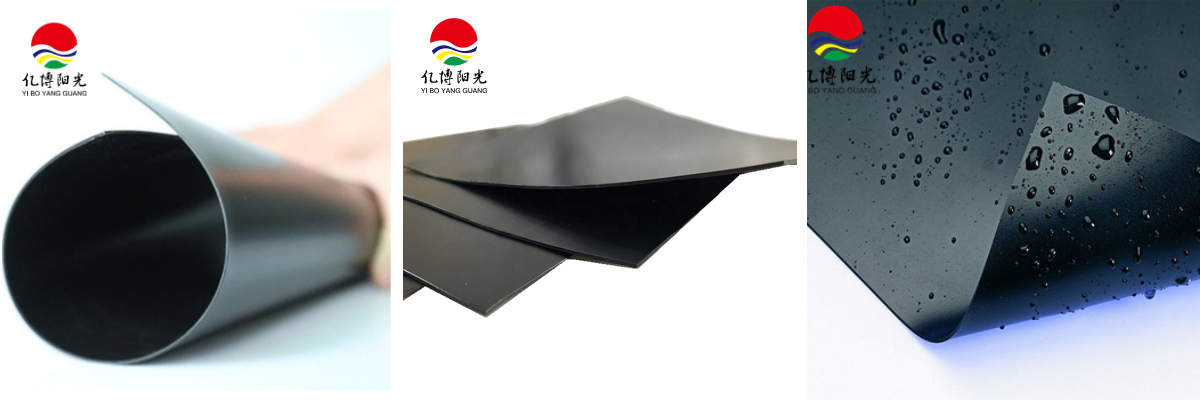

Product Specifcations

Our geomembrane liner offers flexible specs for diverse needs: thickness 0.1-3.0mm, width 1-12m, and length customizable to engineering designs or customer requirements. Its versatility ensures reliable performance in landfill containment, water conservancy, and environmental remediation projects

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane Liner (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

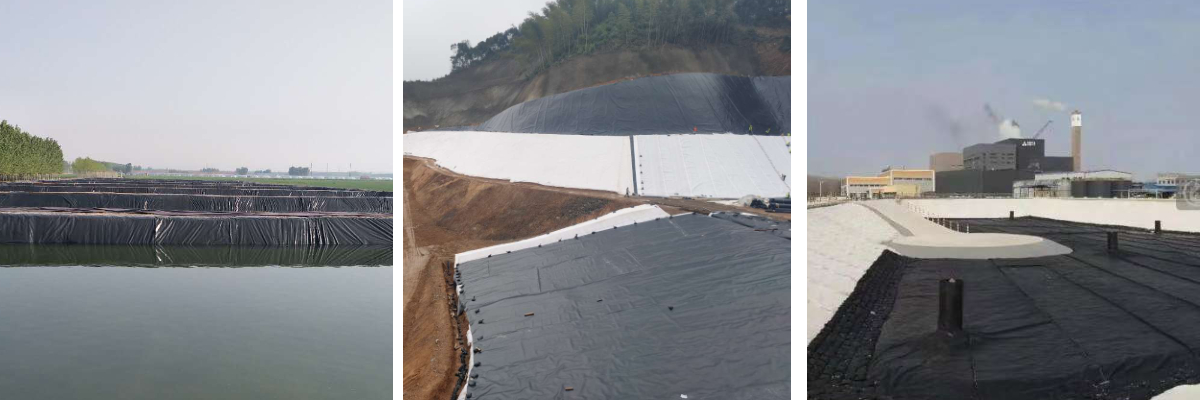

Application Scenarios

Our geomembrane lining is mainly used in projects such as hazardous waste landfill lining, petrochemical tank embankments, coastal flood barriers, mining leachate collection systems, and large-scale hydroponic farm bases. It is designed to cope with harsh environments and complex requirements, providing consistent sealing, leakage control, and environmental protection to achieve safe and efficient performance.

Packaging & Delivery

Our geomembrane lining is mainly used in projects such as hazardous waste landfill lining, petrochemical tank embankments, coastal flood barriers, mining leachate collection systems, and large-scale hydroponic farm bases. It is designed to cope with harsh environments and complex requirements, providing consistent sealing, leakage control, and environmental protection to achieve safe and efficient performance.

About Us

We have an annual production capacity of 10000 tons and a warehouse of 20000 square meters, ready to meet large-scale and urgent supply needs at any time. Our core product line includes impermeable geomembranes, geomembrane liners, and reinforced composite drainage pads - each carefully designed to provide reliable performance in various engineering and environmental applications