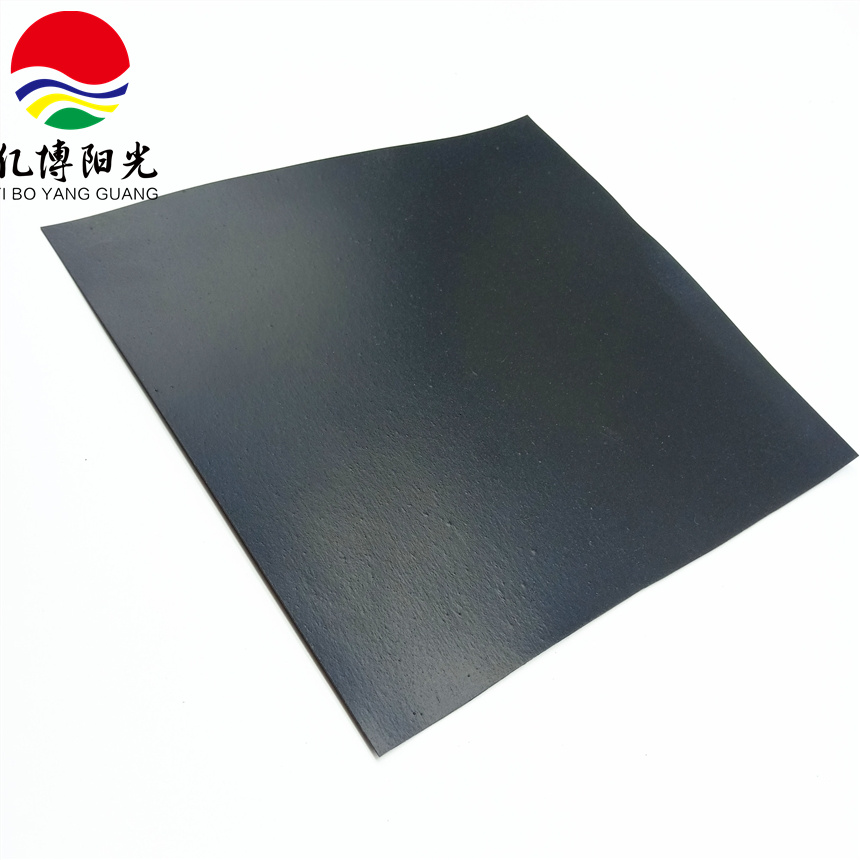

Durable LLDPE Geomembrane

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

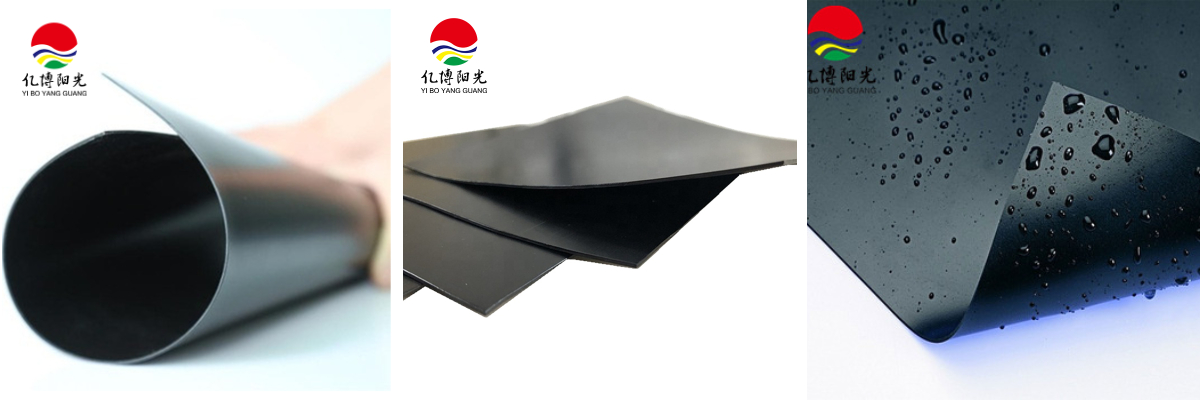

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

Compared to traditional HDPE (high-density polyethylene) geomembranes, LLDPE geomembranes offer the following advantages due to their unique molecular structure (a linear backbone with short side chains)

Excellent flexibility and high elongation

Excellent environmental stress crack resistance (ESCR)

Good low-temperature resistance

Strong puncture resistance

Good chemical stability

Product Specifications

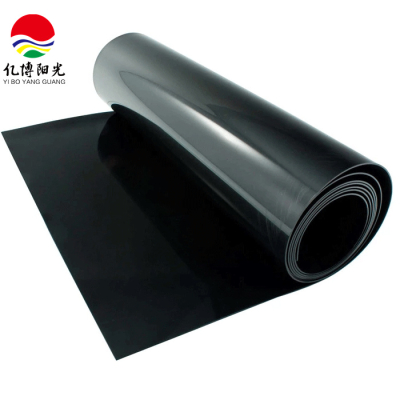

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

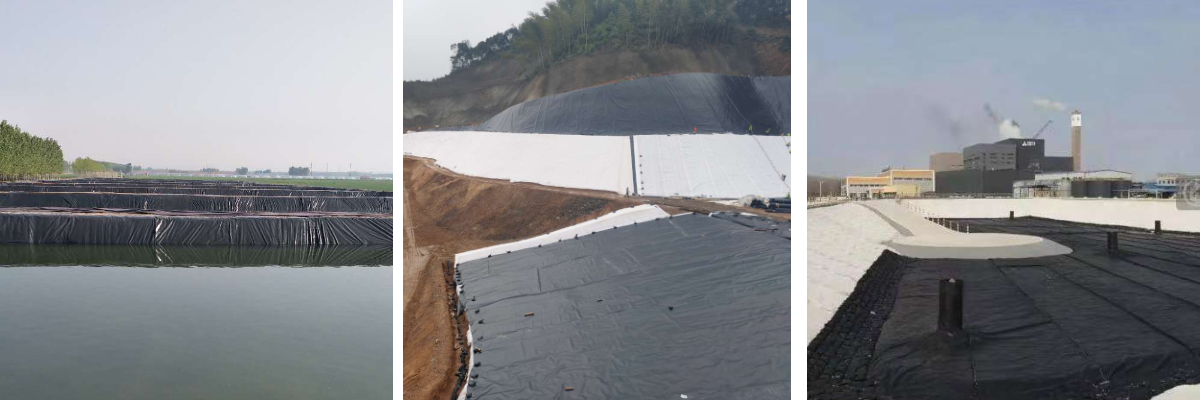

Application Scenarios

Rooftop gardens/greening: Serves as a waterproof root barrier for planted roofs, preventing moisture from penetrating the building structure and effectively preventing plant roots from piercing the waterproofing layer.

Airport and port projects: Used for isolation and anti-seepage beneath road foundations.

Municipal utility corridors and tunnel projects: Used in the waterproofing and drainage systems of integrated utility corridors and tunnel structures, ensuring dry underground spaces.

Packaging & Delivery

We ensure your projects stay on schedule through secure, protective packaging and reliable, on-time delivery. Supported by substantial spot inventory and strong production capabilities, we are equipped to expedite order fulfillment for a full range of geosynthetic materials.

Each item is packed with care according to strict industry standards, guaranteeing it arrives at your site in perfect condition, ready for installation.

Key Advantages:

Speed & Responsiveness: Leverage our vast inventory and streamlined production for quick turnarounds.

Guaranteed Condition: Our robust packaging protocols prevent damage in transit.

About Us

We deliver full-cycle, engineered solutions in geosynthetics, covering advanced material development, precision manufacturing, and expert construction services. Our production expertise is focused on a comprehensive suite of products, including various geomembranes (HDPE, textured, composite), waterproofing systems (EVA, polymeric, bentonite), geotextiles, and drainage nets.

Our Company Services

As a specialized manufacturer, our core focus is the production and customization of geomembranes. Our product range includes smooth, textured, and column-point (pillowed) surfaces. We invite potential clients to connect with us for virtual factory visits and to evaluate sample products.