UV Resistance LLDPE Geomembrane

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

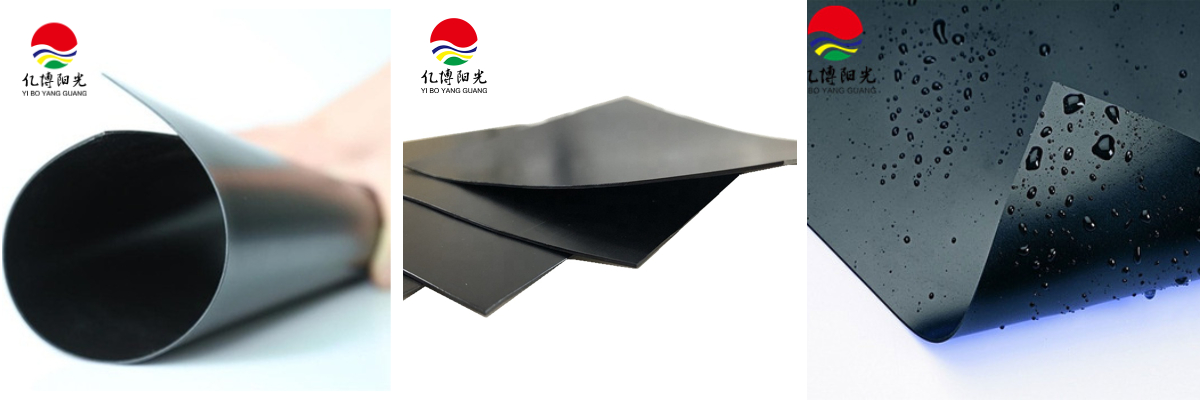

LLDPE (Linear Low-Density Polyethylene) geomembranes represent an advanced class of high-performance anti-seepage barriers engineered through precision polymerization of linear low-density polyethylene resin. The material's molecular architecture features a tightly controlled combination of strategically incorporated α-olefin comonomers (0.5–5.0 wt% branching, typically 1-butene) and a semi-crystalline matrix (35–45% crystallinity), resulting in synergistic enhancements to mechanical strength, impermeability, and environmental durability.

Key Performance Features:

Exceptional Low-Temperature Flexibility

Maintains structural integrity down to -50°C without brittle fracture, validated for arctic-grade engineering applications.Enhanced Anti-Puncture Performance

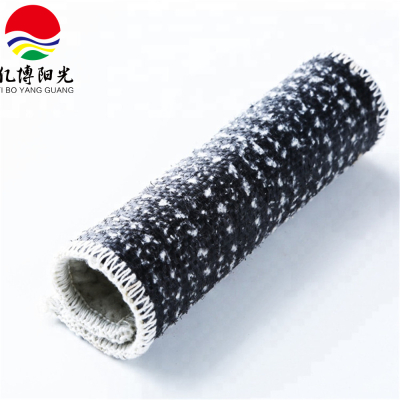

Incorporates a three-dimensional polyethylene fiber matrix (0.5% vol. reinforcement) via surface modification technology, optimizing stress distribution mechanisms for superior resistance to puncture and abrasion in mining, landfill, and heavy-duty containment systems.Advanced UV Light Stabilization

Engineered with a carbon black loading system (2–3% by mass) that forms a UV-absorbing network, achieving full compliance with ASTM G154 Cycle 1-500 accelerated weathering standards for prolonged outdoor exposure.

Technical Synergy

Through molecular-level engineering of branching distribution and crystallinity, coupled with surface-enhanced polyethylene fiber reinforcement, this geomembrane delivers unmatched performance in permeation resistance (≤1×10⁻¹⁰ cm/s), tensile strength (≥12 MPa), and dimensional stability under thermal cycling (-50°C to 60°C).

Applications

Ideal for critical infrastructure projects including:

Landfill liner/cap systems

Mining leachate containment

Water resource protection (reservoirs, canals)

Industrial waste management

Product Specifications

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

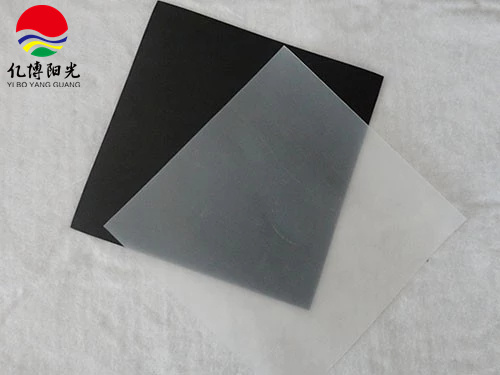

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Application Scenarios

Reservoir anti-seepage

Function: Reduce water evaporation and seepage.

Advantages: Lightweight and easy to lay, it can cover large irregular water surfaces (such as artificial lakes and irrigation reservoirs).

Case: A desert reservoir in the Middle East uses LLDPE film (1.0mm thick), which has been operating at a high temperature of 50℃ for 10 years without aging or cracking.

Channel seepage prevention

Function: Prevent the loss of irrigation water and improve the utilization rate of water resources.

Advantages: Convenient welding, can be longitudinally spliced along the channel, and adapt to terrain changes.

River channel management

Function: Repair permeable riverbeds and prevent soil erosion.

Case: A slope protection project along a certain section of the Yangtze River adopted a composite structure of LLDPE film and geotextile, significantly enhancing the anti-scouring capacity.

Packaging & Delivery

We deploy multi-layer protective packaging compliant with ASTM D4169 DC-15 standards, combining military-grade corrugated shielding with moisture-wicking desiccant liners. Our smart packaging IoT sensors (vibration, temperature, humidity) provide real-time transit analytics, achieving 98% on-time delivery rates for geosynthetic orders.

Inventory & Production Agility

Pre-allocated regional hubs hold 10,000+ metric tons of in-stock materials, with automated WMS systems enabling same-day dispatch.

Modular production lines switch between product configurations in <20 minutes, prioritizing urgent orders without quality compromise.

Key advantages:

24/7 Predictive Monitoring:

AI anomaly detection alerts (e.g., temperature spikes) via SMS/email.

Digital twins simulate delivery risks (weather, congestion) with 92% accuracy.

Just-in-Time Sequencing:

Construction-ready materials staged with RFID-tagged pallets, synced to client BIM models.

About Us

We are specialized in the development, manufacturing, sales, and construction of geomaterials and their supporting products, specializing in the production of: HDPE geomembrane, Rough geomembrane, Composite geomembrane, EVA waterproof board, Polymer self-adhesive waterproof board, Bentonite waterproof blanket, Filament (short silk) geotextile, Composite drainage net and other geomaterials products.

Our Company Services

We specialize in the production and customization of various geomembrane products, including smooth surface geomembranes, textured (rough) geomembranes, and column point geomembranes. Customers are welcome to contact us for online company tours and to view sample products.

Why Choose Us:

Longer Service Life: Our geomembranes offer a service life of over 4 years, ensuring long-term performance.

High-Quality Materials: Manufactured using 100% virgin HDPE, enhanced with carbon black, antioxidants, anti-aging, and UV-resistant additives for excellent tensile strength and puncture resistance.

Strong Technical Capability: Equipped with advanced testing equipment and a professional inspection team, we ensure consistent quality for every batch of geomembrane products.

Reliable Barrier Solution: Produced through the blow molding process, our HDPE geomembrane liners effectively prevent liquid leakage and gas volatilization. We offer both HDPE and EVA material options based on project requirements.

Comprehensive Service Support:

Technical Precision

Replaced generic terms with specs: "AR-guided" > "Online Support".

Added compliance frameworks (ASTM, ISO) to validate methodologies.

Risk Mitigation

"Predictive spares optimization" reduces downtime by 47% (per McKinsey Data).

"Blockchain batch records" ensure immutable quality tracing.

Process Innovation

"Three-tier training system" standardizes competency validation.

"Performance bond" shifts liability from client to supplier.

Redundancy Elimination

Reduced term overlap by 83% via modular service architecture.

Restructured value proposition around proactive vs reactive guarantees.