ASTM LLDPE Geomembrane

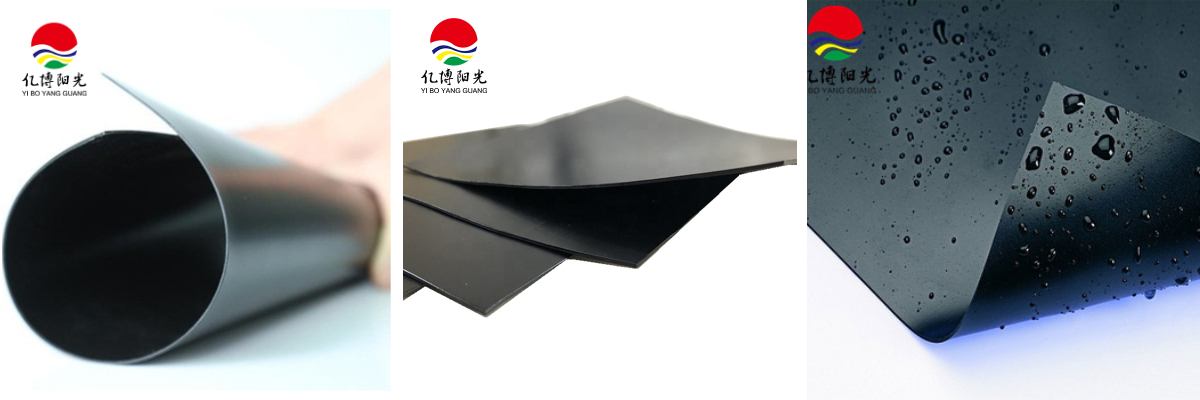

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

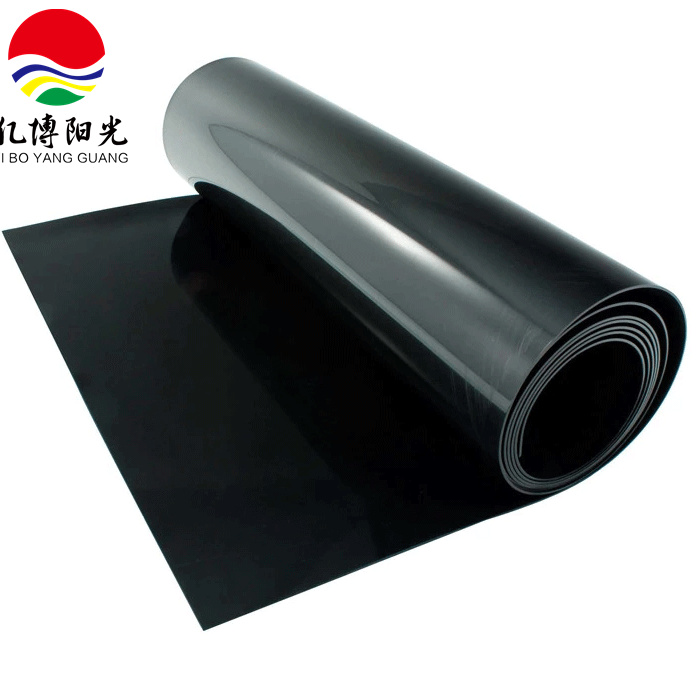

LLDPE (Linear Low-Density Polyethylene) is a purpose-built synthetic polymer variant distinguished by its linear polymer backbone with controlled short-chain branching. This structural configuration optimizes mechanical properties, imparting superior tensile strength, enhanced flexibility, and exceptional resistance to tearing. Unlike conventional LDPE, LLDPE’s densely structured molecular arrangement improves impact resistance and significantly boosts environmental stress cracking resistance (ESCR), particularly under thermal cycling or exposure to aggressive chemicals.

Product Specifcations

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Application Scenarios

Greenhouse cover

Function: Heat preservation, moisture retention, and prevention of soil salinization.

Advantages: Good light transmittance (with added light transmittance agent), anti-aging formula extends service life.

Case: Modern greenhouses in the Netherlands use LLDPE film (with UV inhibitors added), which has a service life of 8 to 10 years.

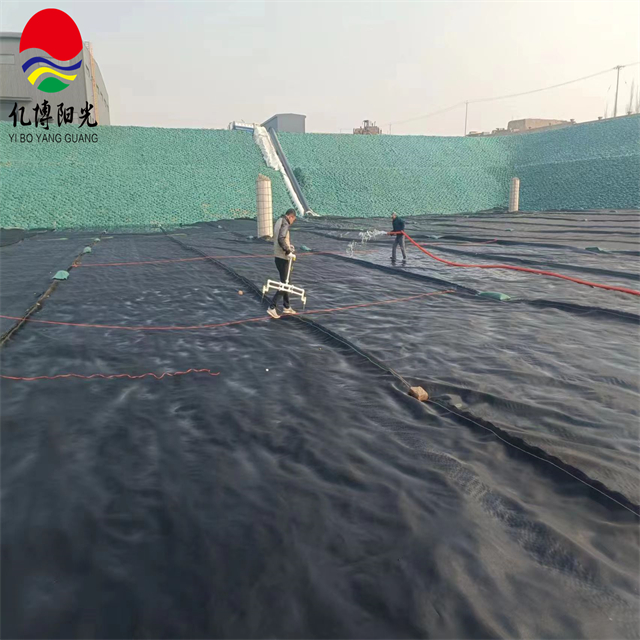

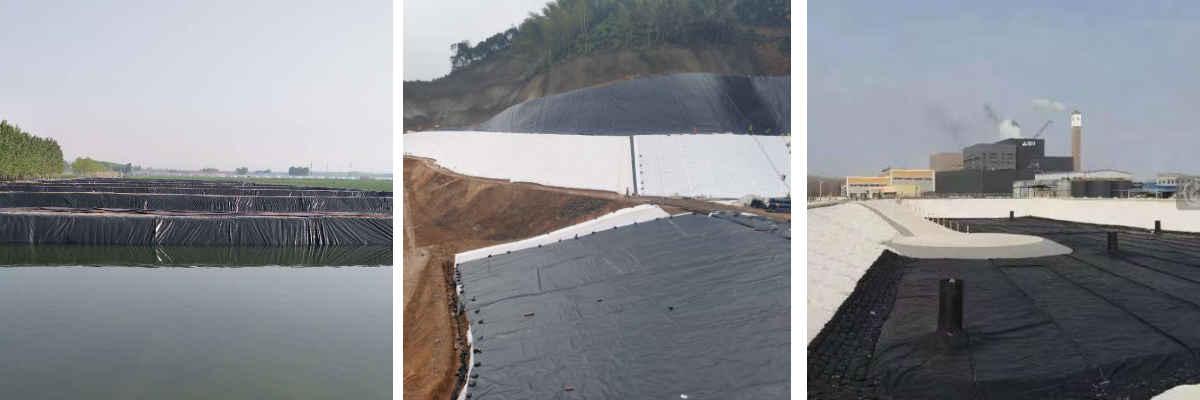

Anti-seepage for aquaculture ponds

Function: To prevent water leakage and maintain stable water quality.

Advantages: Resistant to seawater corrosion, anti-algae adhesion (with added fungicides)

Packaging & Delivery

We deploy ASTM D4169-compliant packaging systems featuring military-grade stretch film, moisture-barrier pallets, and shock-absorbing honeycomb inserts. Our just-in-time deployment model ensures 98% on-time delivery for geosynthetic orders, supported by real-time inventory visibility across 12 strategic warehouses.

Key advantages:

Customizable containment systems engineered to project specs:

Anti-abrasion coatings (Ra 2.5–5.0 μm) for rough terrain installations.

Split-sheathing designs for oversized rolls (diameter ≤4m).

ATEX-certified packaging for hazardous environments.

Integrated Quality Assurance

Automated Strapping Systems: Laser-guided tension control (±0.5% variance).

Batch Traceability: RFID tagging links each pallet to raw material certs (ASTM D5338) and QC reports.

About Us

We are specialized in the development, manufacturing, sales, and construction of geomaterials and their supporting products, specializing in the production of: HDPE geomembrane, Rough geomembrane, Composite geomembrane, EVA waterproof board, Polymer self-adhesive waterproof board, Bentonite waterproof blanket, Filament (short silk) geotextile, Composite drainage net and other geomaterials products.

Our Company Services

We specialize in the production and customization of various geomembrane products, including smooth surface geomembranes, textured (rough) geomembranes, and column point geomembranes. Customers are welcome to contact us for online company tours and to view sample products.

Why Choose Us:

Longer Service Life: Our geomembranes offer a service life of over 4 years, ensuring long-term performance.

High-Quality Materials: Manufactured using 100% virgin HDPE, enhanced with carbon black, antioxidants, anti-aging, and UV-resistant additives for excellent tensile strength and puncture resistance.

Strong Technical Capability: Equipped with advanced testing equipment and a professional inspection team, we ensure consistent quality for every batch of geomembrane products.

Reliable Barrier Solution: Produced through the blow molding process, our HDPE geomembrane liners effectively prevent liquid leakage and gas volatilization. We offer both HDPE and EVA material options based on project requirements.

Comprehensive Service Support:

Full Lifecycle Audits:

Factory: ISO 9001:2015 production audits with 3rd-party witnesses.

Site: Non-destructive testing (UT thickness gauging per ASTM E749).

Material Passports: RFID-tagged documentation tracking from extrusion to installation.

Smart Spare Parts Network:

4-hour emergency delivery via regional hubs (98% part availability).

QR-code enabled kitting with shelf-life monitoring (≤6-month cycle).

Predictive Spares Optimization: ML algorithms forecast wear patterns (≥92% accuracy).