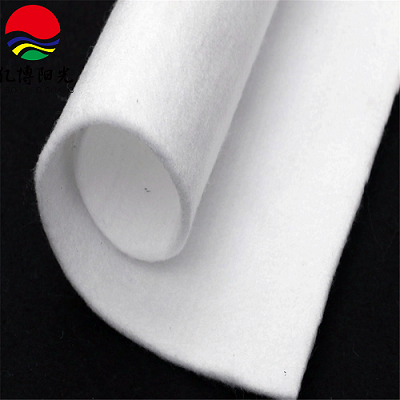

Polyester Staple Fiber Nonwoven Geotextile

High Chemical Resistance: Durable against acids, alkalis, and other chemicals.

UV & Weather Resistant: Reliable performance in outdoor conditions.

Superior Puncture Resistance: Withstands heavy loads and sharp objects.

Excellent Filtration & Drainage: Prevents soil migration while allowing water flow.

Flexible Installation: Easy to cut, weld, and lay on-site.

Cost-Effective: Long service life with minimal maintenance.

Product Introduction

Geotextiles

Geotextiles are permeable geosynthetics made by needling or weaving synthetic fibers. Geotextile is one of the new geosynthetics, finished as cloth. Geotextile has excellent filtration, drainage, isolation, reinforcement and protection properties, light weight, high tensile strength, good air permeability, high temperature resistance, freezing resistance, aging resistance, corrosion resistance and so on.

Product introduction

It is made of ultra-high strength polypropylene staple fiber or ES fiber as the main raw material, and is produced by non-woven process, which has the functions of isolation, reinforcement, protection, filtration, drainage and cushioning.

Product Characteristics

Physical and mechanical properties are 2 to 3 times of traditional products. Low ratio of products of the same gram; excellent acid and alkali resistance, good hot melt adhesion, strong wear resistance. It is more suitable for CRTS/slab ballast sliding layer system, which can reduce the interaction between track system and bridge deck.

Product Specifications

| Material | 100% Polyester (PET) Staple Fiber |

| Fabric Type | Needle-Punched Nonwoven Geotextile |

| Weight Range | 80g/m² – 1500g/m² |

| Width | 1 meter to 8 meters (customizable) |

| Length | Customized based on project requirements |

| Color | White, Black, Grey (or customized) |

| Standards | GB/T17638-2017 — Geosynthetics — Staple Fiber Needle-Punched Nonwoven Geotextile JT/T520-2004 — Geosynthetics for Highway Engineering — Staple Fiber Nonwoven Geotextile |

| Key Features: | High chemical and UV resistance Excellent puncture and tear strength Superior water permeability and filtration Flexible and easy to install Long-lasting and cost-effective performance |

Application

Widely used in geotechnical engineering such as Water Conservancy, Electricity, Mines, Roads and Railways.

1. Filter material for Soil Separation;

2. Drainage materials for the benefication of Reservoirs & Mines, and foundations of High-rise Buildings;

3. Anti-scouring materials for River Dykes and Slope Protection;

4. Reinforcing materials for Railways, Highways, and Airport Running Road foundations, and Road-rise Building ;

5. Anti-frost and anti-freeze insulation materials;

6. Anti-cracking material for asphalt pavement.

Packaging & Delivery

Delivery time: 7-10 working days after receipt of deposit

Reel size: width and length can be customized, each reel is equipped with two lifting straps

Packaging: Reel with core tube; double UV stabilized woven bag

About Us

The products operated by Yibo include: glossy/through-surface geomembrane, composite geomembrane, polyester spunbonded filament geotextile, high-strength woven geotextile,

polyester/polypropylene staple fiber geotextile, three-dimensional composite drainage net, bentonite waterproof blanket, unidirectional/bi-directional geogrid, and other geosynthetics,

The products are widely used in water conservancy, transportation, urban waste treatment, industrial solid waste/hazardous waste treatment, tailing ponds, environmental pollution control and other environmental engineering fields.

Our Company Services

Quality Assurance

We have professional laboratory and our products satisfy the ASTM GRI-GM13 standard.In addition,we have obtained CE,ISO9001,ISO14001,ISO45001 certificates.

After-sales service

1.Engineering adaptation consulting

Provide guidance on material selection and structural design for river training, landfill lining and other scenarios.

Output durability implementation program under extreme working conditions such as freeze-thaw resistance and chemical erosion resistance.

2.Production Quality Assurance

Relying on imported equipment (German/Italian production line) to realize process precision control, heat shrinkage ≤ 1.5%.

Perform full inspection + sampling dual-track quality inspection, covering 20+ indicators such as dimensional tolerance, permeability coefficient, etc.