PET Filament Geotextile

High Chemical Resistance: Durable against acids, alkalis, and other chemicals.

UV & Weather Resistant: Reliable performance in outdoor conditions.

Superior Puncture Resistance: Withstands heavy loads and sharp objects.

Excellent Filtration & Drainage: Prevents soil migration while allowing water flow.

Flexible Installation: Easy to cut, weld, and lay on-site.

Cost-Effective: Long service life with minimal maintenance.

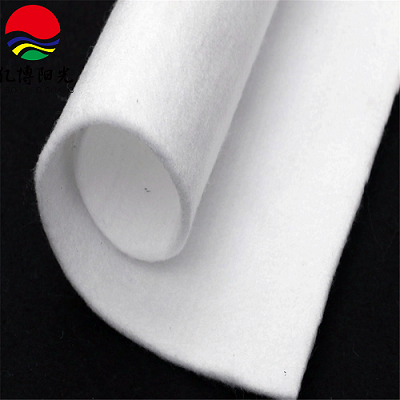

Product Introduction

Filament geotextiles are divided into two systems, polyester (PET) filament geotextiles and polypropylene (PP) filament geotextiles, according to their materials, and their core advantages are reflected in:

1. Durability advantages

Chemical stability: acid and alkali resistance (pH 1-14 environment strength retention rate > 95%), salt and alkali erosion resistance (NaCl solution immersion 1000h without degradation)

2. Ageing resistance: UV stabilizer modification treatment, outdoor exposure for 5 years fracture strength retention rate ≥ 80

3. Mechanical properties

High strength: longitudinal breaking strength ≥ 35kN / m (ASTM D4595 standard)

Low creep: 1% fixed load elongation <3% (ISO 10319 test)

4. Functional Characteristics

Precise filtration: pore size gradient structure (O₉₀ = 70-200μm) to achieve dynamic soil retention and drainage.

Dimensional stability: hot rolling process to control thermal shrinkage ≤ 1.5% (GB/T 15788 specification)

Product Specifications

Material | 100% Polyester (PET) Staple Fiber |

Fabric Type | |

Weight Range | 80g/m² – 1500g/m² |

Width | 1 meter to 8 meters (customizable) |

Length | Customized based on project requirements |

Color | White, Black, Grey (or customized) |

Standards | GB/T17638-2017 — Geosynthetics — Staple Fiber Needle-Punched Nonwoven Geotextile JT/T520-2004 — Geosynthetics for Highway Engineering — Staple Fiber Nonwoven Geotextile |

Key Features: | High chemical and UV resistance Excellent puncture and tear strength Superior water permeability and filtration Flexible and easy to install Long-lasting and cost-effective performance |

Application

1、Hydraulic engineering

Anti-seepage and anti-filtration system: Used in seepage control structures of embankment dams and channel linings to prevent soil loss and maintain hydraulic stability through two-way anti-filtration function.

Drainage system construction: embedded within the earth dam to realize vertical/horizontal drainage channels, reducing pore water pressure; for tunnel seepage control, it can reduce the external water load on the lining structure.

2、Traffic Engineering

Roadbed reinforcement and isolation: as the isolation layer between road base layer and ballast, soft ground, preventing material mixing; enhance the deformation resistance of railroad roadbed, airport runway and other structures through reinforcement.

Crack prevention and control: repair road cracks and inhibit the expansion of reflection cracks to extend the service life of asphalt pavement.

3、Environmental protection and municipal engineering

Pollution prevention and control barrier: composite use with geomembrane in landfills to protect the impermeable layer from mechanical damage; efficient solid-liquid separation in sewage treatment ponds.

Ecological restoration support: used in river training and coastal protection projects to stabilize slopes and reduce soil erosion through stress diffusion mechanism.

4、Industrial and Special Scenarios

Mine management: covering the initial dam surface of tailing dams as an anti-filtration layer to control the migration of mine waste; reinforcing the slope structure of open-pit mines.

Agriculture and horticulture: laying on the soil surface to inhibit the growth of weeds and improve moisture retention capacity; greenhouse ground cover to achieve temperature and humidity control.

Packaging & Delivery

Delivery time: 7-10 working days after receipt of deposit

Reel size: width and length can be customized, each reel is equipped with two lifting straps

Packaging: Reel with core tube; double UV stabilized woven bag

About Us

Located in Jinan, Shandong Province, China, YBYG are a comprehensive service provider and solution provider integrating design, production and construction.

The main products are PET and PP geotextiles, High Density Polyethylene (HDPE) geomembranes, LDPE geomembranes, LLDPE geomembranes, composite geomembranes, drainage nets, cement blankets and so on.

With a perfect quality control system, our product quality, technology and equipment are at the leading level of the industry. Our goal is to become a world-class company dedicated to providing comprehensive, reliable and high-quality services and solutions to our customers.

Our Company Services

Quality Assurance

1. Regularly or according to the requirements of customers, we entrust national testing organizations to carry out quality testing.

2. Strictly according to the international quality system standards, we monitor and manage the whole process of production, quality testing and measurement to ensure product quality.

3. we provide return, exchange and repair service for construction delay or unqualified construction due to quality reasons (except for damage or loss caused by customer's responsibility or irresistible natural disasters), and we will reply to customer's feedback on quality problems within 24 hours.

After-sales service

1. In order to provide customers with comprehensive technical support, we will provide timely technical and other related information upon request.

2. According to the needs, we will assign professional technicians to the construction site to provide technical training to the construction personnel and provide technical guidance during the whole construction process.

3. For damages caused during transportation and delivery, after receiving complaints, we will verify them through the pictures and videos provided, and if it is confirmed to be our responsibility, we will provide free replacement.

4. After the construction is completed, according to your request, our technicians can participate in the final acceptance.