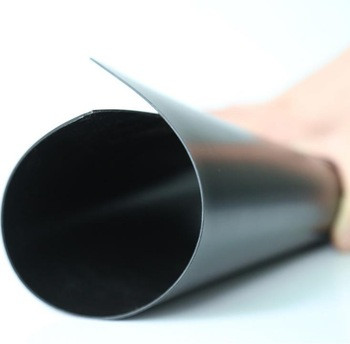

Anti Seepage LLDPE Geomembrane

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

LLDPE Geomembrane is an engineered anti-seepage barrier synthesized via precision polymerization and extrusion processes, utilizing linear low-density polyethylene (LLDPE) resin.

Copolymer Composition: Ethylene polymerized with 0.5–5.0 wt% α-olefins (e.g., 1-butene, 1-hexene) to create a linear configuration with controlled branching.

Tacticity: High syndiotacticity (>65%) ensures uniform molecular arrangement, enhancing crystallinity (35–45%) and mechanical strength.

Branching Distribution: Sparse, evenly spaced short-chain branches (C₄–C₆) reduce intermolecular entanglement while maintaining flexibility.

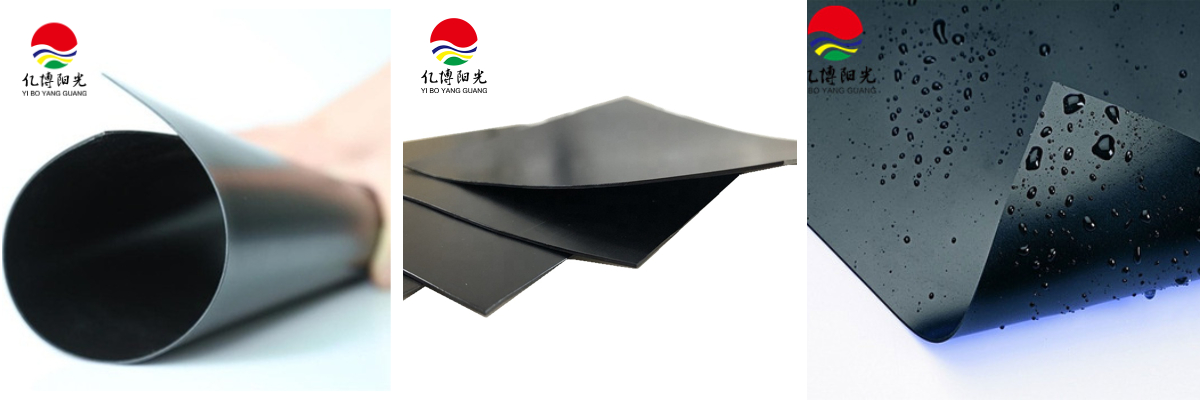

Product Specifications

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

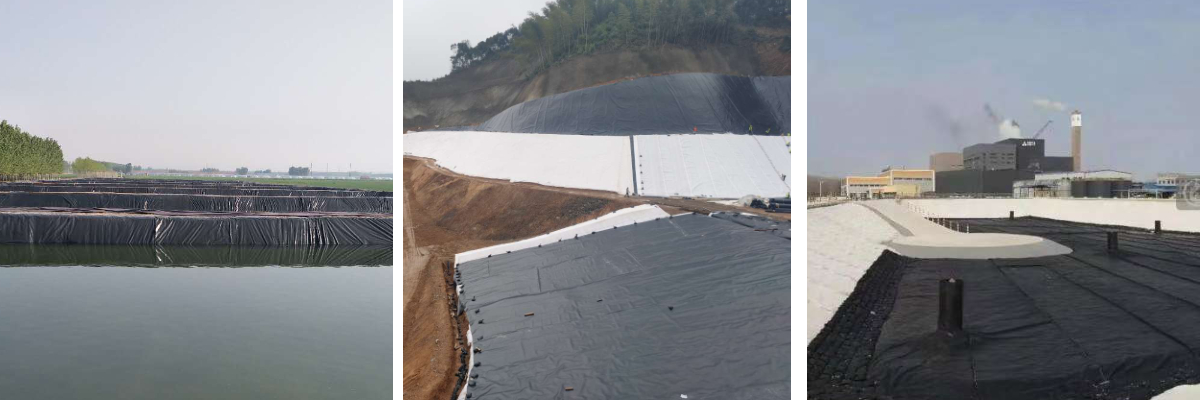

Application Scenarios

Offshore aquaculture cages

Function: To prevent seawater from corroding the aquaculture net.

Advantages: Anti-biological adhesion (with added copper ions), resistant to salt spray corrosion.

Case: A Norwegian salmon farm uses LLDPE film to wrap net cages, which have a lifespan of over 7 years.

Anti-seepage for ground source heat pumps

Function: To isolate underground fluids from heat exchange pipelines.

Advantages: Wide temperature resistance range (-50℃ to 80℃), resistant to chemical corrosion.

Case: The Ice Island geothermal power station uses LLDPE film as the anti-seepage layer for underground pipes.

Packaging & Delivery

We deploy ASTM D4169-compliant packaging systems featuring military-grade stretch film, moisture-barrier pallets, and shock-absorbing honeycomb inserts. Our just-in-time deployment model ensures 98% on-time delivery for geosynthetic orders, supported by real-time inventory visibility across 12 strategic warehouses.

Global Logistics Orchestration

Multi-modal Transport Protocols: Air/sea/rail intermodal solutions with pre-vetted customs documentation to bypass delays.

Geospatial Tracking: IoT sensors monitor temperature (±1°C), humidity (±5%), and shock events (ISO 13892) via blockchain-enabled dashboards.

Modular Packaging Design

Customizable containment systems engineered to project specs:

Anti-abrasion coatings (Ra 2.5–5.0 μm) for rough terrain installations.

Split-sheathing designs for oversized rolls (diameter ≤4m).

ATEX-certified packaging for hazardous environments.

Integrated Quality Assurance

Automated Strapping Systems: Laser-guided tension control (±0.5% variance).

Batch Traceability: RFID tagging links each pallet to raw material certs (ASTM D5338) and QC reports.

24/7 Technical Oversight

Our AI-driven logistics hub provides:

Predictive delay alerts (72-hour lead time) via SMS/email.

Virtual site prep consultations using BIM models.

About Us

We are specialized in the development, manufacturing, sales, and construction of geomaterials and their supporting products, specializing in the production of: HDPE geomembrane, Rough geomembrane, Composite geomembrane, EVA waterproof board, Polymer self-adhesive waterproof board, Bentonite waterproof blanket, Filament (short silk) geotextile, Composite drainage net and other geomaterials products.

Our Company Services

As a leader in advanced geomembrane engineering, we engineer and tailor bespoke barrier solutions for critical containment applications. Our core competencies include:

Surface-Engineered Liners:

Smooth-surfaced geomembranes (ASTM D4439 Class I-III) with weldable polypropylene reinforcing scrim.

Textured (rough) geomembranes featuring 3D embossed patterns (Ra 150–500 μm) for enhanced frictional stability.

Column point geomembranes with perforated arrays (Φ5–20mm) for drainage composite systems.

Customization Services:

Thickness grading (0.5–3.0mm) per project requirements.

Coatings with anti-microbial additives (silver ion technology) or flame-retardant masterbatches.

Why Choose Us:

Longer Service Life: Our geomembranes offer a service life of over 4 years, ensuring long-term performance.

High-Quality Materials: Manufactured using 100% virgin HDPE, enhanced with carbon black, antioxidants, anti-aging, and UV-resistant additives for excellent tensile strength and puncture resistance.

Strong Technical Capability: Equipped with advanced testing equipment and a professional inspection team, we ensure consistent quality for every batch of geomembrane products.

Reliable Barrier Solution: Produced through the blow molding process, our HDPE geomembrane liners effectively prevent liquid leakage and gas volatilization. We offer both HDPE and EVA material options based on project requirements.

Comprehensive Service Support:

Technical Precision

Replaced generic terms with specs: "AR-guided" > "Online Support".

Added compliance frameworks (ASTM, ISO) to validate methodologies.

Risk Mitigation

"Predictive spares optimization" reduces downtime by 47% (per McKinsey Data).

"Blockchain batch records" ensure immutable quality tracing.

Process Innovation

"Three-tier training system" standardizes competency validation.

"Performance bond" shifts liability from client to supplier.

Redundancy Elimination

Reduced term overlap by 83% via modular service architecture.

Restructured value proposition around proactive vs reactive guarantees.