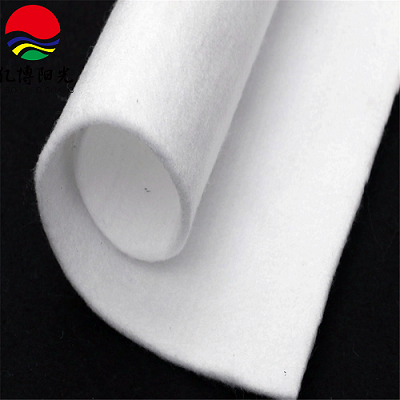

White Polyester Nonwoven Geotextile

High Chemical Resistance: Durable against acids, alkalis, and other chemicals.

UV & Weather Resistant: Reliable performance in outdoor conditions.

Superior Puncture Resistance: Withstands heavy loads and sharp objects.

Excellent Filtration & Drainage: Prevents soil migration while allowing water flow.

Flexible Installation: Easy to cut, weld, and lay on-site.

Cost-Effective: Long service life with minimal maintenance.

Product Introduction

1. Special high-strength polyester chips are used as raw materials, and the load-bearing capacity is further improved through the process of opening, removing impurities and needling.

2. High tensile strength, aging resistance and long service life.

3. Not easy to deform and decompose, can keep the original characteristics for a long time.

4. Acid-resistant, alkali-resistant, moth-proof and mold-proof.

5. Good water permeability.

6. Resistant to high temperature, severe cold and cold, and can be applied to different external environments.

Product Specifications

| Material | 100% Polyester (PET) Staple Fiber |

| Fabric Type | Needle-Punched Nonwoven Geotextile |

| Weight Range | 80g/m² – 1500g/m² |

| Width | 1 meter to 8 meters (customizable) |

| Length | Customized based on project requirements |

| Color | White, Black, Grey (or customized) |

| Standards | GB/T17638-2017 — Geosynthetics — Staple Fiber Needle-Punched Nonwoven Geotextile JT/T520-2004 — Geosynthetics for Highway Engineering — Staple Fiber Nonwoven Geotextile |

| Key Features: | High chemical and UV resistance Excellent puncture and tear strength Superior water permeability and filtration Flexible and easy to install Long-lasting and cost-effective performance |

Application

1. Segregation

The use of geotextiles to isolate materials with different physical properties (particle size, distribution, density and thickness, etc.) (e.g. soil and gravel soil, soil and concrete, etc.). So that two or more materials do not mix with each other, to maintain the overall structure and function of the material, is the structure of the bearing capacity has been strengthened.

2. Filter

When the water flows from fine-grained material into the soil layer of coarse-grained material, the needle punched geotextile's good air permeability and water permeability is utilized to allow the water to pass through, and effectively intercept the soil particles, cyclones, and small stones, so as to maintain the stability of the soil and water engineering.

3. Drainage

Needle-punched geotextile is a good hydraulic material, which can form drainage channels from within the soil to remove excess liquid and gas from the soil structure.

4. Reinforcement

Needle-punched geotextiles are utilized to enhance the tensile strength and deformation resistance of the soil and increase the stability of the building structure in order to improve the quality of the soil.

5 . Protection

Focus on effective stress diffusion, transfer or breakdown by external forces to prevent damage to the soil.

6 Sealing

An impermeable layer of insulation formed by a needle-punched geotextile in conjunction with other materials, primarily asphalt or plastic film. (Mainly used for road resurfacing and repair, etc.).

Packaging & Delivery

Delivery time: 7-10 working days after receipt of deposit

Reel size: width and length can be customized, each reel is equipped with two lifting straps

Packaging: Reel with core tube; double UV stabilized woven bag

About Us

Professional geomembrane manufacturer in China

The first 8-meter wide geomembrane production line in China

Annual output ≥20,000 tons

More than 20 years of production experience

Professional geomembrane testing equipment and strict quality control.

Undertaking domestic and overseas projects for more than 30 years

Quality certified by SGS, BV and other third-party testing organizations.

Products are exported to more than 120 countries worldwide.

Our Company Services

Quality Assurance

1. Regularly or according to the requirements of customers, we entrust national testing organizations to carry out quality testing.

2. Strictly according to the international quality system standards, we monitor and manage the whole process of production, quality testing and measurement to ensure product quality.

3. we provide return, exchange and repair service for construction delay or unqualified construction due to quality reasons (except for damage or loss caused by customer's responsibility or irresistible natural disasters), and we will reply to customer's feedback on quality problems within 24 hours.

A: We are factory.

Q: Is the quality of your products stable?

A: The company has a complete QC system, and each batch of products will be sampled and the samples will be kept for 5 years.

Q: Can you do OEM?

A: Yes, of course. We can produce the products exactly as your request.

Q: Do you provide samples ? Is it free or extra ?

A: Yes, we offer the sample for free but do not pay the cost of freight.

Q: How long does your delivery take?

A: Generally it takes 5-10 days if the goods are in stock;Otherwise it will take 10-15 days (of course, it depends on quantity at the same time).