Corrosion Resistant HDPE Geomembrane

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

Geomembrane is a premium quality, high-molecular-weight, high -density polyethylene (HDPE) geomembrane produced from specially formulated, virgin polyethylene resin. It delivers superior fluid containment, barrier protection and environmental isolation for a variety of civil, environmental and industrial applications. Due of its high grade physical and chemical propperty, HDPE geomembrane has been widely used by designers and owners for more sustainable yet cost effective solutions.

Product Specifcations

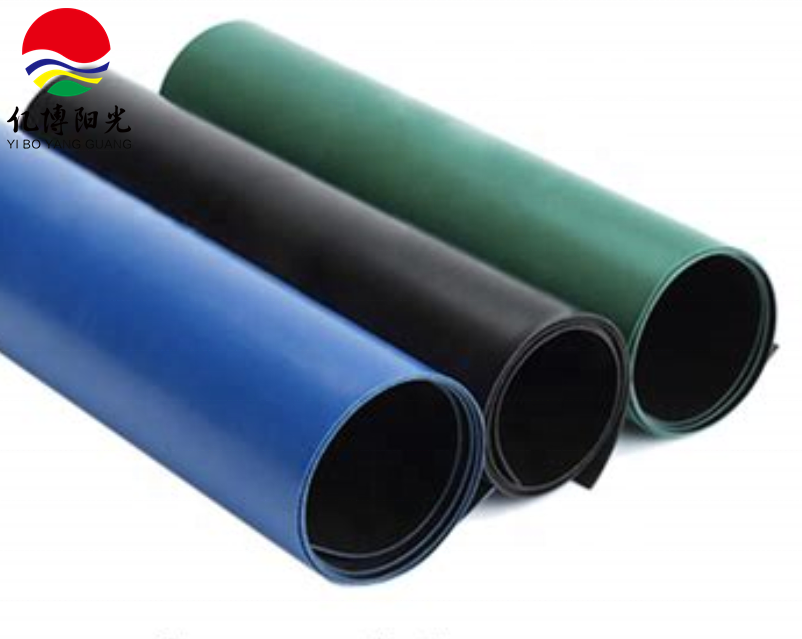

Thickness 0.1-3.0mm, width 1-12m, length according to engineering design and customer requirements.

Parameter | Specification |

Thickness | Smooth surface 0.2mm–3.0mm, textured surface 1.0mm–2.0mm |

Width | Smooth surface 1m–8m, textured surface 4m–8m |

Length | 30m–200m/roll or as requested |

Material | HDPE, LDPE, LLDPE |

Classification | Smooth / Rough / Composite Geomembrane |

Surface | Smooth surface, single surface textured, dual surfaces textured |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

Features & Benefits of Our HDPE Geomembrane

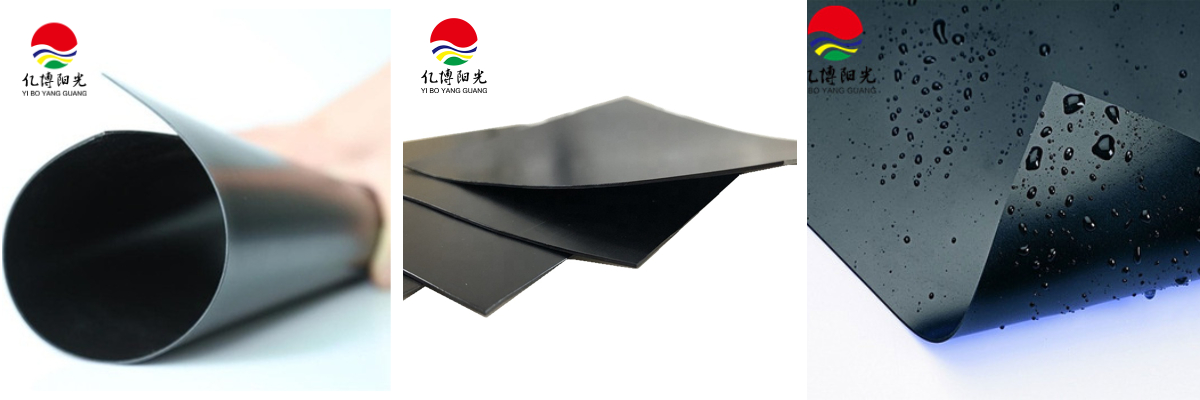

Superior Strength & Puncture Resistance: Our HDPE liner is a broadly used geomembrane that stands up to extremely tough environments and stressless applications. It is resistant to extreme temperatures (-60 – 80 °C), UV radiation and mechanical stress ensuring long-term integrity (>50 years) in typical applications. This is good, because the life, beauty and durability of your project depends on it

ExcellentChemical Resistance :HDPE has excellent resistance to a Mile wide range of aggressive chemicals, acids, alkalis and organic fluids. It is perfect for placement in landfills, wastewater treatment plants, chemical storage ponds and mines where high levels of corrosive materials are prevalent. This also protects its surroundings and prevents from leaking.

Extremely low permeability: Our HDPE geomembrane is a good option because of its excellent impermeable performance. Its permeability coefficient is lower than 1×10⁻¹³ cm/s, which could effectively prevent liquid and gas migration and provide a reliable containment. This is critical for applications like drinking water reservoirs, irrigation channels and hazardous waste containment structures.

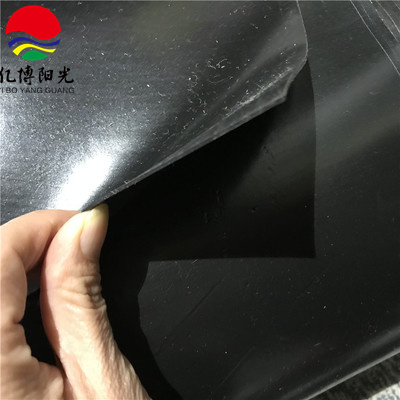

Easy to Install & Weld: Light weight and easy handing, radiation resistance in open air and direct sun. It can be joined together by a process of heating and cooling to form joints that are as strong as the pipe itself, and is flexible but tough like PE. This maintains a solid barrier and lessens the chance of leaks at joints.

Eco-Friendly & Reusable: Our HDPE geomembrane liner is made of non-toxic and food-grade polyethylene material, safe for both environmental and human. It is entirely recyclable upon the end of its working life, supporting both your green aspirations and sustainable development objectives. Opting for our HDPE geomembrane will help decrease the carbon footprint of your project and facilitate green construction initiatives.

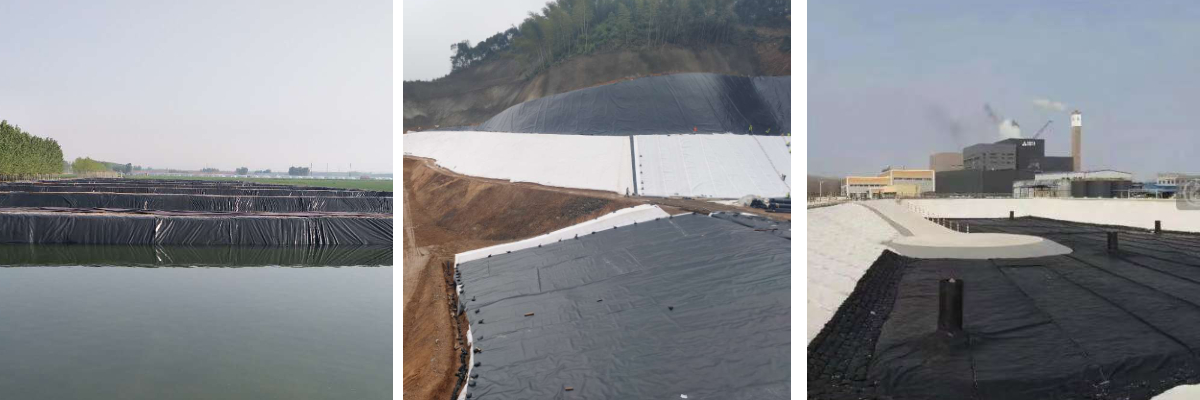

Application Scenarios

Mining Operations: Tailings pond liners and heap leach pad containment

Renewable Energy: Solar farm evaporation ponds and wind turbine foundation barriers

Urban Infrastructure: Underground parking waterproofing and subway tunnel membranes

Food Processing: Secondary containment for edible oil storage tanks

Disaster Recovery: Temporary flood barriers and hurricane debris containment

Eco-Tourism: Artificial reef bases and safari park water features

Military Engineering: Fuel depot liners and mobile decontamination units

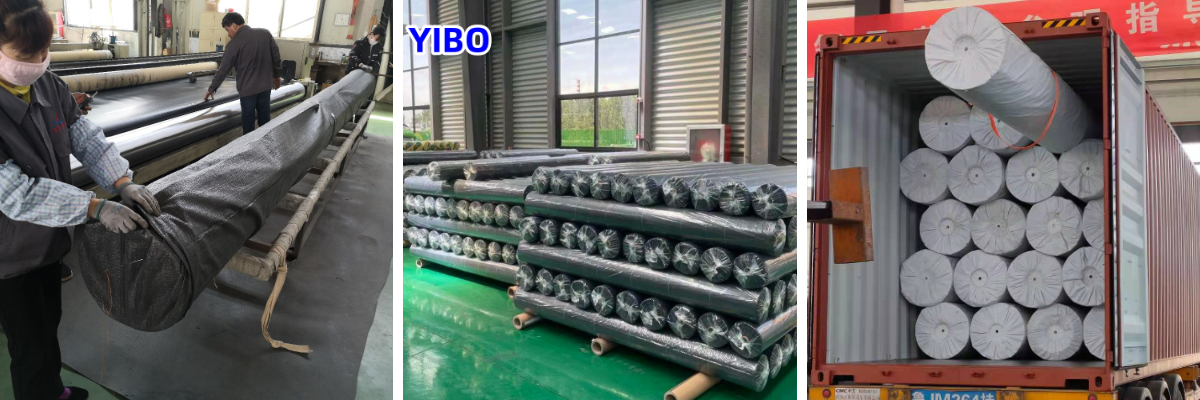

Packaging & Delivery

Custom-engineered crates with RFID tracking tags ensure traceability. Expedited air freight options available for urgent projects.

Key Logistics Features:

Moisture-Proof Barrier Layers

Anti-Static Packaging for Sensitive Areas

Dangerous Goods Certification (ICAO/IATA)

Multi-Language Safety Data Sheets

About Us

A global supplier with 12 patented technologies in geosynthetics, specializing in:

Electrically conductive geomembranes

Anti-root penetration barriers

High-temperature resistant LDPE liners

Geosynthetic clay liners (GCL)

Our Company Services

Compliance-driven solutions from design to decommissioning.

Value-Added Services:

Carbon Footprint Reporting

Leak Detection System Integration

Custom Embossing Patterns