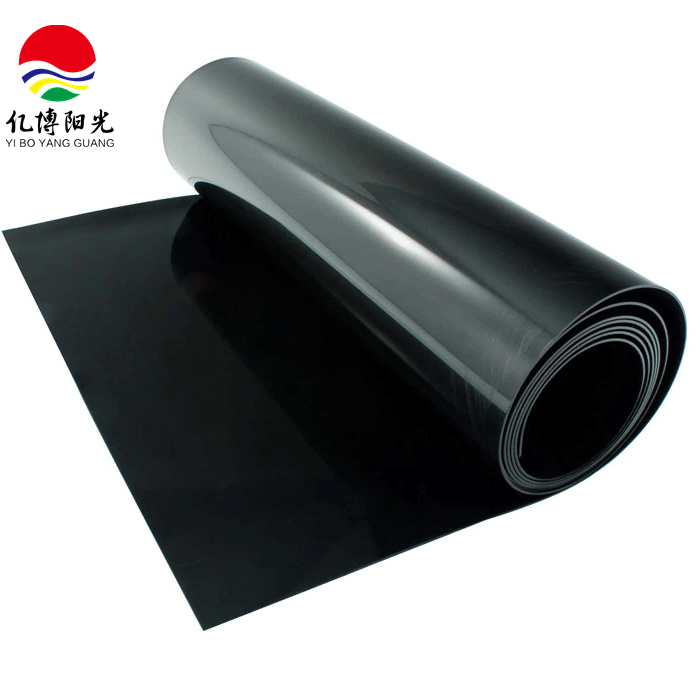

Gm13 LLDPE Geomembrane

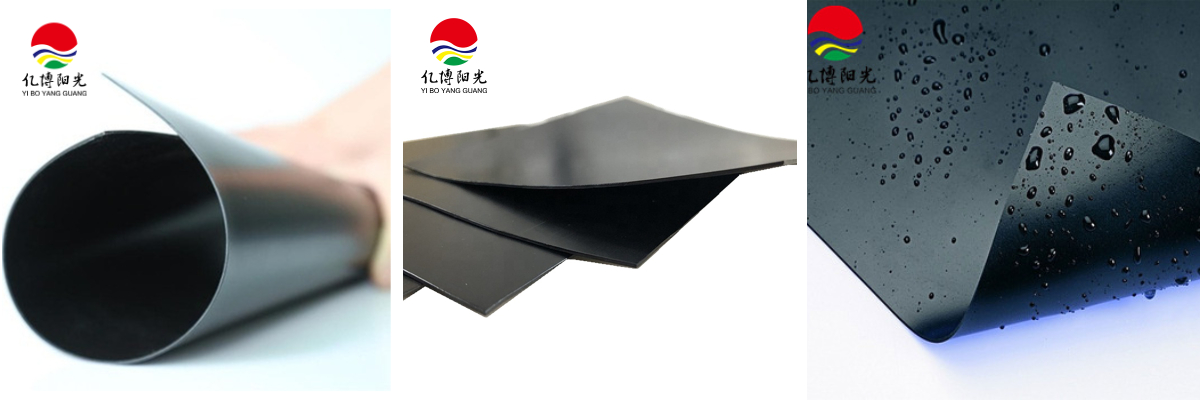

High Chemical Resistance: Excellent durability in harsh environments.

UV & Weather Resistant: Long-lasting performance outdoors.

Superior Puncture Strength: Withstands heavy loads and sharp objects.

Low Permeability: Ideal for effective seepage control.

Flexible Installation: Easy to weld and shape on-site.

Cost-Effective Solution: Long lifespan with minimal maintenance.

Product Introduction

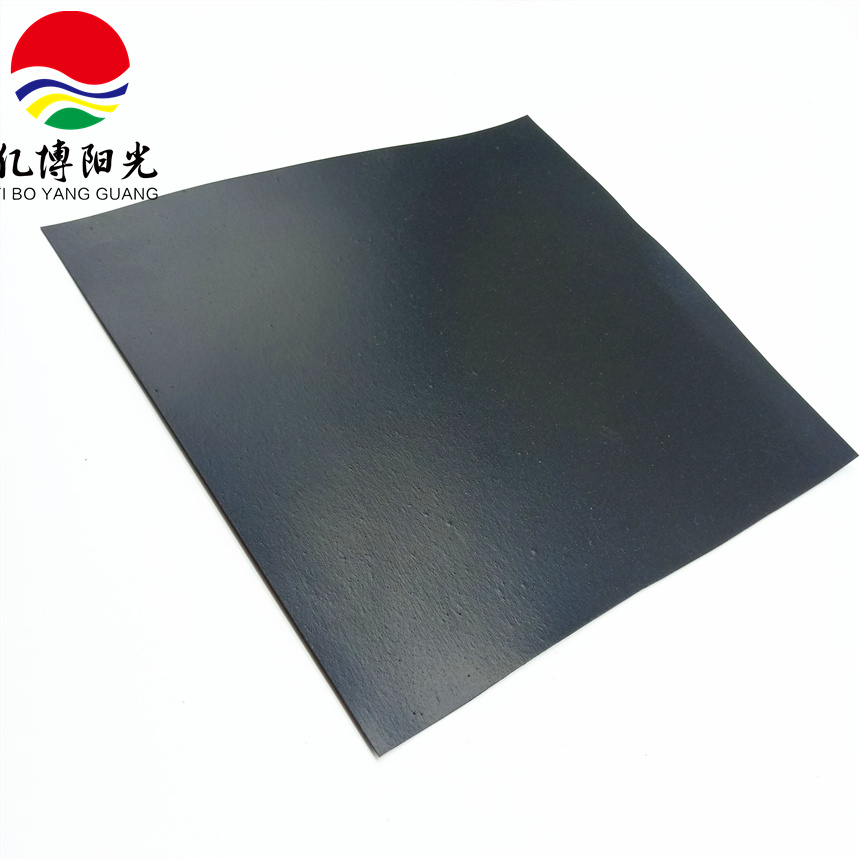

LLDPE geomembrane is mainly applied in various anti-seepage projects in different fields. Polyethylene geomembranes can be classified into high-density polyethylene (HDPE) geomembranes and linear low-density polyethylene (LLDPE) geomembranes based on the different resins selected. LLDPE double-smooth geomembrane is a type of geomembrane product with smooth surfaces on both sides. Compared with HDPE geomembrane, it has a better elongation at break, excellent puncture resistance and the ability to withstand multiple strains. LLDPE geomembrane is fully applicable to anti-seepage applications such as landfill sites and their closures, or any other applications with extremely uneven settlement, such as bioreactor landfills.

Product Specifcations

Parameter | Specification |

Strength of extension | Longitudinal (MD) : 15-30 MPa, transverse (TD) : 10-25 MPa |

Elongation at break | ≥500% |

Puncture strength | ≥200 N |

CBR puncture strength | ≥300 N |

Item | Geomembrane (Customizable parameters) | ||||||||

Item | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

Density (g/cm³) | ≥0.940 | ||||||||

Tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

Tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

Elongation at yield (%) | – | – | – | – | – | – | ≥11 | – | – |

Elongation at break (%) | ≥600 | ||||||||

Right-angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

Puncture strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

Carbon black content (%) | 2.0–3.0 | ||||||||

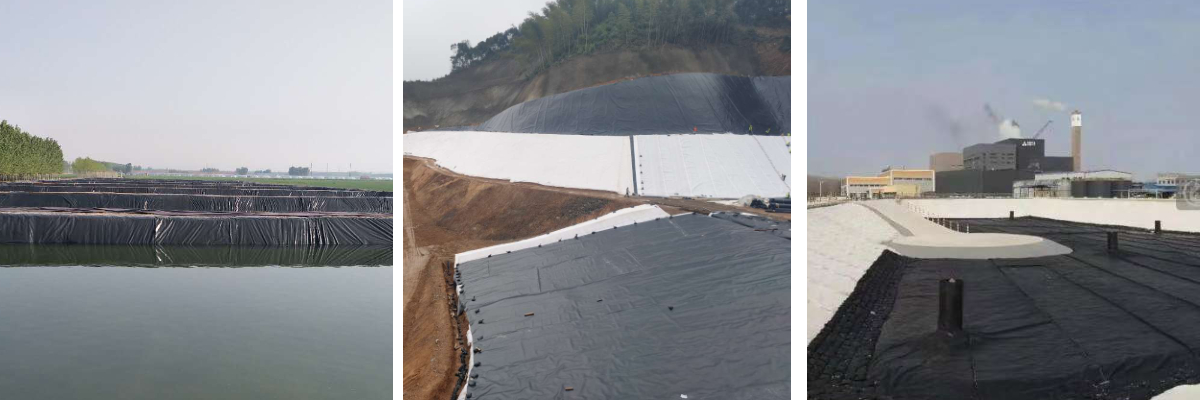

Application Scenarios

Mining anti-seepage: Anti-seepage for tailings ponds and waste rock dumps to prevent heavy metal pollution.

Post-disaster emergency seepage prevention: Temporary containment of pollutants or accumulated water after a flood.

Basement seepage prevention: Repair basement leakage to prevent groundwater from eroding the structure.

Tunnel lining: As a waterproof layer for tunnels, it prevents groundwater from seeping in.

Packaging & Delivery

We guarantee seamless project execution through our rigorous packaging protocols and precision-managed logistics, ensuring geosynthetic material orders arrive intact and on schedule. Backed by strategic inventory reserves and 24/7 production capabilities, we deliver 98% of orders within 72 hours using military-grade protective wrapping that eliminates transit damage risks. Our quality-first approach combines AI-powered quality control systems with ISO-certified handling procedures to preserve product integrity from factory to installation site.

Key advantages:

Logistics Assurance Framework

Just-in-Time Dispatch Protocol: Immediate shipment activation for in-stock inventory with real-time warehouse management system (WMS) tracking

Global Multi-modal Transport Network: Integrated sea/rail/air freight coordination with customs pre-clearance capabilities (incoterms 2020 compliant)

Military-Grade Protection System:

Custom-engineered packaging solutions with moisture-resistant film laminates (ASTM D7703 certified) Shock-absorption matrix achieving ≤0.5g vibration tolerance (ISO 13355 testing standard)

Engineered Packaging Configurations: Available modular systems for oversized loads (up to 15m x 3m x 3m)

Smart Supply Chain Operations

Our IoT-enabled logistics platform provides:

24/7 shipment telemetry via GPS/RFID hybrid tracking

Predictive delay alerts with 98% accuracy (machine learning-based)

Blockchain-backed documentation for cross-border compliance

About Us

We are specialized in the development, manufacturing, sales, and construction of geomaterials and their supporting products, specializing in the production of: HDPE geomembrane, Rough geomembrane, Composite geomembrane, EVA waterproof board, Polymer self-adhesive waterproof board, Bentonite waterproof blanket, Filament (short silk) geotextile, Composite drainage net and other geomaterials products.

Our Company Services

We specialize in the production and customization of various geomembrane products, including smooth surface geomembranes, textured (rough) geomembranes, and column point geomembranes. Customers are welcome to contact us for online company tours and to view sample products.

Why Choose Us:

Predictive Failure Analysis:

IoT-enabled sensors monitor strain (≤0.5% FS) and temperature (±0.5°C)

Cloud-based platform delivers failure alerts 72h in advance

BIM-Driven Installation:

3D model pre-visualization for complex geometries (AutoCAD Civil 3D compatible)

Laser-guided welding system (seam strength ≥28 MPa)

Certified Technician Training:

5-day immersion program (includes ASTM D7703 standard certification)

AR-assisted troubleshooting simulations

Smart Spare Parts Network:

Blockchain-tracked inventory with 4-hour emergency delivery capability

QR code-enabled traceability for all components