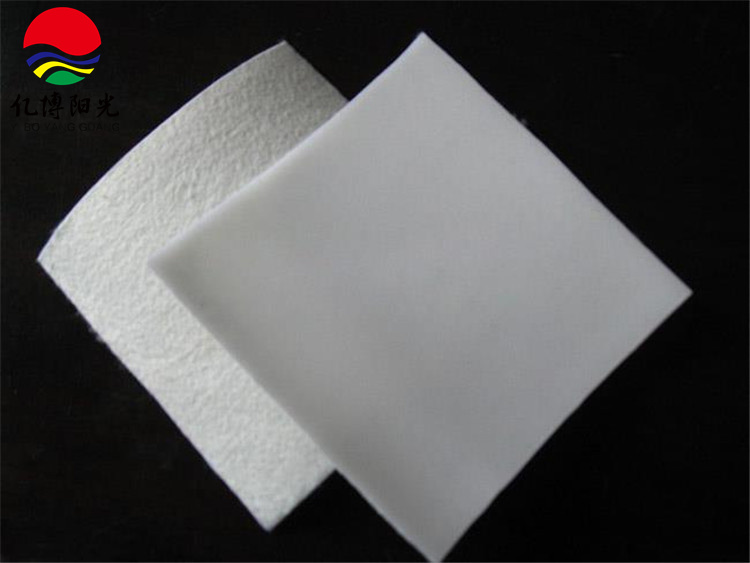

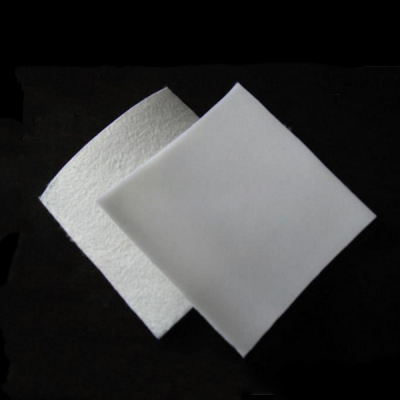

250g m2 White Geotextile Fabric

High Chemical Resistance: Durable against acids, alkalis, and other chemicals.

UV & Weather Resistant: Reliable performance in outdoor conditions.

Superior Puncture Resistance: Withstands heavy loads and sharp objects.

Excellent Filtration & Drainage: Prevents soil migration while allowing water flow.

Flexible Installation: Easy to cut, weld, and lay on-site.

Cost-Effective: Long service life with minimal maintenance.

Product Introduction

250g/m² White Geotextile Fabric is a type of geosynthetic material, characterized by its weight of 250 grams per square meter and its common white color. It is a permeable fabric, typically made from synthetic fibers like polypropylene (PP) or polyester (PET) through manufacturing processes such as needle-punching . This specific weight offers a balance of strength, durability, and functionality for various civil engineering and construction applications.

Product Specifications

| Material | 100% Polyester (PET) Staple Fiber |

| Fabric Type | Needle-Punched Nonwoven Geotextile |

| Weight Range | 80g/m² – 1500g/m² |

| Width | 1 meter to 8 meters (customizable) |

| Length | Customized based on project requirements |

| Color | White, Black, Grey (or customized) |

| Standards | GB/T17638-2017 — Geosynthetics — Staple Fiber Needle-Punched Nonwoven Geotextile JT/T520-2004 — Geosynthetics for Highway Engineering — Staple Fiber Nonwoven Geotextile |

| Key Features: | High chemical and UV resistance Excellent puncture and tear strength Superior water permeability and filtration Flexible and easy to install Long-lasting and cost-effective performance |

Application

Landfill and Environmental Protection: In environmental engineering, the fabric is valued for its filtering and protective qualities.

Gardening and Landscaping: In residential and commercial landscaping, its aesthetic white color and functionality are highly appreciated.

Packaging & Delivery

Roll securing: Fabric rolls are typically wound around cardboard tubes or steel mandrels to maintain shape stability and prevent deformation during transport. Some suppliers also reinforce the rolls with coated woven fabric on both sides and affix product information labels. Loading and unloading assistance: For heavy-duty rolls (such as large 4x100-meter rolls), some manufacturers equip them with two load-bearing slings (e.g., 2.5-ton slings), greatly facilitating mechanical loading and unloading at ports and construction sites, improving safety and efficiency.

About Us

The company emphasizes quality control through pre-production samples and final inspections. It offers comprehensive services, including onsite installation support, technical training, 3D project design, and warranties up to 3 years. With over 20 years of industry experience, Yibo Yangguang combines technical expertise with a customer-centric approach to deliver reliable engineering solutions.

Our Company Services

Professional Project Consultation & Design Support

Our team of experienced engineers provides expert consultation from the initial project stage. We assist with material selection, application-specific solution design, and technical drawings, helping you optimize project design for cost-efficiency and performance.